- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric time

Results for

Electric time - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The double anodization process can be used to create a protective anodization layer on various parts of a consumer electronic product, including top and bottom portions, side walls, and chamfered portions. It’s particularly useful for improving corrosion resistance and wear resistance, and it provides better adhesion for paint primers and glues than bare metal does. The process is not limited to aluminum; it can also be applied to other metals like titanium, zinc, magnesium, and others. However, aluminum is the most common due to its widespread use in consumer electronics and other applications where weight and durability are important factors.Double anodization is a complex process that requires precise control over the electrolytic solutions, electrical current, and time to ensure the desired outcome. It’s a testament to the advancements in materials engineering and its ability to tailor the properties of metals for specific applications.

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The parts to be washed are placed on stainless steel rotative basket and are washed with water mixted with degreaser under high pressure. Washing is done in order to clean oil, sawdust, dirt and wastes on dirty surfaces from different angles by means of time-adjusted pressurized water nozzles according to the part structure and pollution rate. By filtering the water with the recirculation system, the machine is designed to wash parts with minimum consumption of water, detergent, electricity and time.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product Name: Copper Tin Nickel Alloy Width:10-630mm Material:Bronze Grade: Oxygen Free Copper Cu (Min): 75% Model Number:Copper Alloy Place of Origin: China Size: Customised Standard: JIS ASTM DIN EN ISO Certificate: SGS / ROHS / ISO9001:2008 Package: standard export packing Price Term: CIF CFR FOB Ex-Work etc. Usage: Electric Components Lead time:20 Days

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

CHARACTERISTICS •Design and manufacturing of orientation moulds were carried out •Having high dimensional precision and impact-resistance •Capable of forming products with inlay •The injection moulding parts are suitable for forming products with various shapes and thin walls •Multi polar magnetization can be carried out as per customer's requirements APPLICATIONS •Different kind of micro-special motor •Different kind of fan motor •Different kind of DC motor •Synchronization electric motor •House electric apparatus •Ice chipper electric motor •Hand-operated electric generator •Automobile motor •Time gauge •Instruments for auto

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Klöpper Therm electric flow boilers are used for generating hot water in heating units for direct heating, storage operation or for Power to Heat systems. As an alternative to other energy types in new buildings or when converting central heating units, these boilers offer a universal range of applications radiator heating, floor heating, mixed systems or bivalent operation with other energy types. Depending on the relevant operating conditions of the energy supplier, the boilers are used for direct or storage heating by utilising free electric power during off peak times.

Request for a quote

EMBRO GMBH

Germany

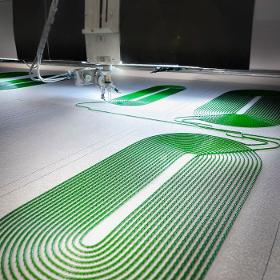

Where are magnetic field mats used? The coils currently manufactured by us are processed by our customers into so-called electromagnetic field mats. These mats are used in Pulsed Electromagnetic Field (PEMF) therapy. Many PEMF devices are suitable for private use at home. However, various health service providers including physical therapists as well as non-medical practitioners offer therapies based on magnetic fields. Why is our embroidery technology used for production? This technique creates circular-shaped structures that form the basis for a homogeneous flow/direction of the electric current. At the same time, the mechanical wire laying has an extremely high level of accuracy. The distances can also precisely be determined. How is the magnetic field created? Simply put, this is how electromagnetic fields are created: pulsating magnetic fields are generated by the electric current flowing through the wire. The more wire, the stronger the magnetic field.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

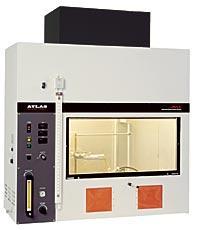

The Atlas HVUL2 Horizontal Vertical Flame Chamber is designed for the flammability testing of plastic materials used in consumer electric devices and appliances. The chamber is constructed of stainless steel with a black interior and large sliding window for easy viewing. The HVUL2 includes a fully adjustable specimen support and a precision metered gas burner. Three digital timers with remote control are mounted on the inside back wall of the chamber, allowing for precise and simplified operation. Burner angle adjustable to 0º, 20º, 45º Flexible iris hand access ports Remote burner positioning Sliding tempered glass viewing window Removable burner carriage assembly Flexible laboratory fixturing Interior light Digital timers located in line of sight with specimen Digital timers with resolution of 0.1 sec Remote control with push button reset for in-chamber event timing. Electrical gas shut-off solenoid Gas control system Flame confirmation kit (ASTM D5207) Black interior finish Performs all UL 94 tests (Except Section 10.0 Radiant Panel Test) Bench top chamber (Volume greater than 0.75 m 3) Tirril Burner Multi-directional specimen and burner positioning apparatus Quick release mount for burner during manual operation Large sliding, tempered-glass window for test viewing Exhaust blower (1/3 hp) with variable speed control (580 cfm in free air) Sliding damper for draft free chamber Manometer/pressure gauge, 300 mm Four flame height and sample gauges Interior Dimensions: 122 cm (48'') W x 112 cm (44'') H x 60 cm (23.5'') D Exterior Dimensions: 122 cm (48'') W x 140 cm (55'') H x 61 cm (24'') D Bench Weight: 163 kg (360 lbs) Simple burner angle adjustment (0°, 20°, 45°) Specimen holders for all five Bunsen burner tests Digital timers for specimen test duration, 0.1 sec. resolution Remote control with push button reset for in-chamber event timing Quick release mount for burner during manual operation Hand access openings with irises for closed window access

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

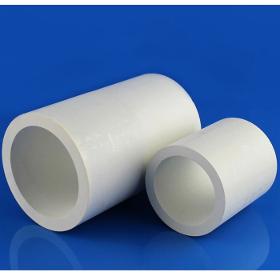

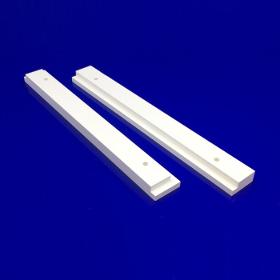

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

JOYOR E-MOVING S.L

Spain

The Joyor X1 and X5S electric scooters are all time best sellers of Joyor Electric Scooter. Joyor X1 has a 400W motor and a range of 35km. Electric scooter Joyor X1 is very light and powerful. Joyor X5S has a 500W motor and a range of 50km. Both Joyor X1 and X5S electric scooters have front suspension and front and rear lights powered by LCD screen. These electric scooters are limited to 25km/h (maximum speed recommended by most European regulations). The Joyor X1 and X5S electric scooters arevery well balanced and stable with large 10" tires. These electric scooter are economical considering their high performance.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Analogue version ▪ 5-pin connection ▪ Can be used with all analogue Hydraulic Testers of the PPC series ▪ CAN version ▪ 5-pin SPEEDCON connection plug ▪ Housing: Aluminium (black anodised) ▪ Gaskets: FPM (Viton®) ▪ Accuracy (at 21 cSt): ±1 (% FS*) or ±1 (% of the displayed value) ▪ Pressure measurement connection: SMK20 (M16 x 2) ▪ Temperature measurement connection: M10 x 1 (standard screw plug) ▪ Calibration certificate on request ▪ UNF version on request Ambient Conditions ▪ Media temperature: -20 °C ... +90 °C / -4 °F ... +194 °F ▪ Ambient temperature: -10 °C ... +50 °C / +14 °F ... +122 °F ▪ Storage temperature: -20 °C ... +80 °C / -4 °F ... +176 °F ▪ Permissible particle size: < 10 Micron for SFM-015 < 25 Micron for others ▪ Viscosity range: 10 ... 100 cSt Electrical Data ▪ Response time: 50 ms ▪ Flow Turbine (analogue): A PPC-04/12-CAB3 (3 m / 9.84 ft) Connection Cable is needed to connect the sensor to the current Hydraulic Testers. A PPC-04/12-CAB5-EXT (5 m / 16.40...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Analogue version ▪ 5-pin connection ▪ Can be used with all analogue Hydraulic Testers of the PPC series ▪ Input voltage: 9 ... 36 V DC ▪ Output signal: 0 ... 3 V DC ▪ CAN version ▪ Indication of the sensor status via LED ▪ 5-pin SPEEDCON connection plug ▪ CANopen protocol profile DS406 v3.2 with manufacturer-specific additions ▪ LSS service DS305 v2.0 ▪ Sturdy Stainless Steel housing (1.4301) ▪ FPM (Viton®) gasket ▪ Weight: 85 g / .19 lbs ▪ Suitable for gases and liquids (in the case of aggressive media, only after consultation) ▪ Accuracy (±0,25% FS* typ.) ▪ Automatic sensor recognition ▪ Process Connection G1/4 (without adaptor) ▪ Calibration certificate on request Ambient Conditions ▪ Media temperature: -25 °C ... +105 °C /-13 °F ... +221 °F ▪ Ambient temperature: -25 °C ... +85 °C / -13 °F ... +185 °F ▪ Storage temperature: -25 °C ... +85 °C / -13 °F ... +185 °F ▪ Load cycles (10 6): 100 Electrical Data ▪ Response time: 1 ms ▪ Long-term stability: < 0,2 % FS* /a ▪ Vibration...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The industry's most popular, work-horse carbon probe. Alloy protection tube for versatility and ruggedness. Accepted as an industry standard, around the world. • Available in multiple insertion lengths up to 47" (1200mm) • 1.05" diameter, schd. 40 sheath eliminates probe sag problems found on competitor probes - no need to periodically rotate the probe in order to prevent failure • Can be inserted up to 10" inside the furnace - no 4" limit as found on smaller diameter products • Genuine RA330 alloy sheath - we don't substitute cheaper alloys like the competition! • K", "R", and "S" integral thermocouples are available • Fast probe burn-off (90 seconds) and rapid recovery time • Probe electrical disconnect allows for simple replacement • Strain-relief grommet for direct-to-terminal wiring

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts Characteristics SIM-Marker Compact: — mechanical Z-axis, manual adjustment of the focal point with adjusting wheel — Opening and closing of lift door with operating button (electrical) — Lift door opening time < 2.0 sec. — PC-Link — Set up: directly on a desk or mounted onto the movable base frame — Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive — mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position by means of a Hall sensor and signal processing including generation of the output signal - in addition to the angular position, a speed signal can also be output in digits / time unit - electrical connection via screw clamp (5-pin, conductor cross-section max. 0.5 mm²) or PTFE pigtail connector, 300 mm long - a CAN controller at the output enables connection to the CANopen network. According to CANopen Application Layer and Communication Profile, CiA Draft Standard 301, Version 4.1 and according to Device Profile for Encoders CiA Draft Standard Proposal 406, Version 3.0 and CANopen Layer setting Services and Protocol (LSS), CiA DSP 305. In the multiturn version, the number of revolutions is recorded in a counter. The position value is saved on shutting off the supply voltage. In voltage-free condition, the position value is recorded on movement of the shaft in a range of ≤ ± 90°.

Request for a quote

TRIO UKRAINE LLC

Ukraine

It gives gentle heat without drying the air and burning the oxygen (the surface temperature does not exceed 85 ° C) It consumes 3-4 times less electricity than regular heaters (consumption – 400 W) It ia safe

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELCOM, S.R.O. PREŠOV

Slovakia

8-inch touch screen provides the accountant with a comfortable overview of ongoing payments. In addition, the screen backlight offers exceptional readability even in extremely bright environments. Faster, quieter and more reliable receipt printing than you've been used to. A 2-inch thermal printer with a simple drop-in tape change system will help speed up the customer's equipment and a more efficient billing process. Thanks to the excellent technical design, the Euro 80 cash register has up to several times lower electricity consumption at the same output than a regular computer or other cash register equipment. In addition, it is ready to work fully on Android platform. It offers a wide range of communication options with remote devices. 1x USB (guest), 1x USB (OTG), or the possibility of connecting to the Internet via Wifi and LAN will simplify the transfer of data either to the device or for the seller. In addition, the device has multiple ports for connecting external devices.

Request for a quote

EUROMACK

Turkey

AREAS OF USE - Automotive industry - Aircraft industry - Ship industry - Defense industry - Metal industry PRINCIPLE OF OPERATION The parts to be washed on the basket placed on a stainless rotary platform with a sliding system are subjected to rotary basket washing with water with high pressure detergent in a closed cabin to be placed. Washing process is carried out to clean oil, sawdust, dirt and waste from dirty surfaces from different angles by means of time-adjustable pressure water nozzles according to the part structure and pollution rate. By filtering the water with the cycle permanent system, it is designed to reduce the consumption of water, detergent, electricity and time (labor) with the least consumption of parts. OPTIONAL FEATURES - Steam Evacuation Unit - Stainless chrome body structure - Basket structure - Number of nozzles - Liquid level control system All kinds of parts washing machines can be manufactured in our company upon request.

Request for a quoteResults for

Electric time - Import exportNumber of results

20 ProductsCompany type

Category

- Aluminium coatings (1)

- Automation - systems and equipment (1)

- Boilers, cast iron (1)

- Cash registers (1)

- Ceramics (1)

- Ceramics, industrial (1)

- Electric vehicles (1)

- Furnishings - accessories and decorative objects (1)

- High-pressure cleaning machines (1)

- Magnets (1)

- Medical electronics - apparatus and equipment (1)

- Plasma cutting machines (1)

- Potentiometers (1)

- Scooters (1)

- Steels, nickel (1)

- Washing machines, domestic (1)

- Water treatment, industrial - systems and equipment (1)