- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dry steam

Results for

Dry steam - Import export

GENERAL VAPEUR S.R.L.

Italy

MK07 Process is a 12 kW stationary steam generator that can be installed on a production line. It offers greater ease of use than mobile generators and is designed for complex cleaning cycles. It allows the delivery of dry steam at constant pressure during prolonged use, even 24 / 24h. It can be managed automatically by the customer's production line and combined with suction systems. It is possible to position it at a considerable distance from the place of use, for better integration in the spaces made available. It is simple to use and maintain. PRODUCT FEATURES 12 kW (7 lt boiler) Steam production from 15.6 to 39 kg / h Operating pressure 6 bar Steam temperature 165 ° C Positioning the boiler horizontally

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

MK27 Process is a 30kW fixed steam generator that can be installed on a production line. It offers greater ease of use than mobile generators and is designed for complex cleaning cycles. It allows the delivery of dry steam at constant pressure during prolonged use, even 24 / 24h. It can be managed automatically by the customer's production line and combined with suction systems. It is possible to position it at a considerable distance from the place of use, for better integration in the spaces made available. It is simple to use and maintain. PRODUCT FEATURES 30 kW (27 lt boiler) Steam production from 15.6 to 39 kg / h Operating pressure 6 bar Steam temperature 165 ° C Horizontal boiler positioning

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The Steam Max series has been specially designed for professional cleaning. Steam Max and Steam Max Vacuum, with a professional dry saturated steam jet and extraction cleaning function, offers a cleaning system suitable for multiple applications. Steam Max combines technology and flexibility, and is equipped with a series of accessories designed for every need.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The cleaning and sanitizing activities with traditional methods can be replaced with the use of dry saturated steam, with a considerable advantage on the consumption of water and chemical agents. The Steam Masters are steam generators designed for cleaning and sanitizing surfaces, equipment and industrial environments.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

DI20 uses dry saturated steam technology for deep cleaning of machinery and environments. It was made primarily for external cleaning and is easily transportable. The combination of heat and pressure creates a powerful cleaning solution that removes all kinds of dirt, grease, oil, tree yield and bird droppings like no other system can.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GENERAL VAPEUR S.R.L.

Italy

1 outlet with detergent dispensing The cleaning and sanitizing activities with traditional methods can be replaced with the use of dry saturated steam, with a considerable advantage on the consumption of water and chemical agents. The steam masters are steam generators designed for cleaning and sanitizing surfaces, equipment and industrial environments.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

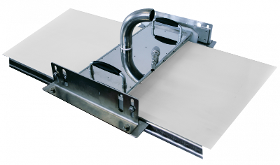

reduction of cleaning costs fast cleaning cleaning in a dry environment speed of change of production on the line portable equipment for different applications cleaning fully integrated systems are available to be installed in the production line the best cleaning unit for belts on the market reduction of chemical disinfectants with the use of dry steam technology reduction of waste water The belt cleaner has been specially designed as an accessory for cleaning synthetic conveyor belts. The jet of steam passes through the mesh and eliminates any deposits or encrustations, guaranteeing perfect sterilization. In flat belts the action of steam, combined with a powerful suction, leave the belt perfectly clean and dry.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The Steam Max series has been specially designed for professional cleaning. Steam Max and Steam Max Vacuum, with a professional dry saturated steam jet and extraction cleaning function, offers a cleaning system suitable for multiple applications. Steam Max combines technology and flexibility, and is equipped with a series of accessories designed for every need.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The cleaning and sanitizing activities with traditional methods can be replaced with the use of dry saturated steam, with a considerable advantage on the consumption of water and chemical agents. The steam masters are steam generators designed for cleaning and sanitizing surfaces, equipment and industrial environments.

Request for a quote

GENERAL VAPEUR S.R.L.

Italy

The nebulizer is based on the principle of the Venturi injector, exploiting a suction effect that forcefully injects the detergent into the dry steam jet, creating an ideal nebulizing mixture to be sprayed on any type of surface. Certified by the SANA srl laboratory, Italy; accredited by ACCREDIA n ° 0747 and UNI EN ISO 17025 2018 standard EVH2O2 SILVER BIO LIQUID DETERGENT It is a combination of hydrogen peroxide and silver nitrate with excellent bactericidal, virucidal and fungicidal properties for a wide range of applications. According to the WHO (World Health Organization) it is effective against the Coronavirus SARS CoV2. It is widely recognized as the most environmentally friendly disinfectant in the world. It has no harmful and toxic effects and is safe for humans, animals and the environment.

Request for a quote

ATAC ELEKTRIK VE MAKINA SANAYI TICARET LTD STI

Turkey

GK40C Continuous Stenter is designed to make Chemical and impregnation application on Fabric samples in laboatories with bulk production conditions. Thermasoling, Fixation, Drying, Heat setting or any similar application can made on 35cm fabrics. Can be designed according to customers demand like Continuous Stenter with Chain, lamination Line, Pad Thermasol line, Pad Dry-Pad Steam line and/or special application Curing line.

Request for a quote

NERO LEATHER & FUR

Turkey

PRODUCT DETAILS -Our product is shearling. -All the materials used in the production of the product are of higher quality compared to their equivalents. -Cutting pattern is normal base. -Metal materials (zipper, buckle, snap) used in our product comply with ISO standards. CARE AND STORAGE CONDITIONS -The product should be stored on thick hangers when not in use. -It should not be stored in a stout way. In case of obligatory folding, the inside of the jacket should be folded to the outside. - If the jacket is wrinkled, it should never be ironed with a hand iron. It should be ironed at a temperature of 100 ° C-150 ° C in the press irons in dry cleaning. Steam should never be given while ironing. -If the product gets wet, it should be left to dry at room temperature. It should never be subjected to a heat source.

Request for a quote

NERO LEATHER & FUR

Turkey

PRODUCT DETAILS -Our product is shearling. -All the materials used in the production of the product are of higher quality compared to their equivalents. -Cutting pattern is normal base. -Metal materials (zipper, buckle, snap) used in our product comply with ISO standards. CARE AND STORAGE CONDITIONS -The product should be stored on thick hangers when not in use. -It should not be stored in a stout way. In case of obligatory folding, the inside of the jacket should be folded to the outside. - If the jacket is wrinkled, it should never be ironed with a hand iron. It should be ironed at a temperature of 100 ° C-150 ° C in the press irons in dry cleaning. Steam should never be given while ironing. -If the product gets wet, it should be left to dry at room temperature. It should never be subjected to a heat source.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary. FUNCTIONAL PRINCIPLE OF THE HOT FILTER PRESS – WITH THERMAL FILTER CAKE DRYING In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press. For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved.

Request for a quote

SCW MACHINE

Turkey

WHY MY STEAM WASHING AUTO? • You will save 97% of the water you will spend in water washing. (Aqueous washing average: 70-80 Lt. Steam Car Wash 3-5 Lt) • You will save 97% of the water you will spend in water washing. (Aqueous washing average: 70-80 Lt. Steam Car Wash 3-5 Lt) • When you wash by steam, you wash in 1 hour, while cleaning the outer car. You spend 3-4 hours in the water wash. Why spend extra time? • No brushing required! Thus, the car seats do not damage, wear. • Steam cleaning is hygienic. • Steam gives the car a smooth, vibrant and brighter appearance. • Provides cleaning that you will never get in water washing. WHY IS SCW MACHINE? • CE Certificate (compliance with European Standards) • Internal 10 Ml boom boiler • Washing the inside and outside of the same machine with the same machine (no energy loss) • Up to 33 Lt tank capacity • 15 kW machine • One machine is both dry steam. (Dry steam provides special cleaning for electronic components and breasts.)

Request for a quoteResults for

Dry steam - Import exportNumber of results

16 ProductsCountries

Company type