- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive roller

Results for

Drive roller - Import export

KRAUS BETRIEBSAUSSTATTUNG UND FÖRDERTECHNIK GMBH

Austria

In our offer you will find motor rollers with a diameter of 30 mm to 168 mm. Motor rollers are well suited for both container and pallet conveyor technology.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work services are fully adapted to meet your facilities maintenance and safety needs : replacement and/or modification of walkways installation and/or modification of ventilation ducts manufacture and installation of floors and access doors on production lines welding of reinforcements on to machine frames modification of fabric drive systems, presses, cylinders and rollers modification of pneumatic and hydraulic control systems installation of conveyor lines mechanical protective equipment: grids, gratings, walkways and doors machine guarding: stainless steel, steel, etc. We guarantee a highly flexible and adaptable service, while meeting all of your production requirements and maintaining the configuration of your existing facilities.

Request for a quote

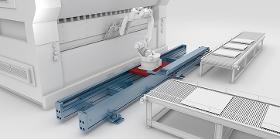

ROLLON GMBH

Germany

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable for highstrength steel applications Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

Most simple threading Short setup as roller adjustment can be maintained with coilchanges Most comfortable maintenance and cleaning Synchronized drive of all bottom work rollers and both pinch rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive Movable base Manual or hydraulic loop bridge... etc.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Drive wheels are used to drive appliances and equipment. They use the force generated by a motor within the appliance to get it moving. One area where they are currently used is in the drum systems of wind turbines. Blickle has developed a heavy duty drive roller for the wind power industry. Click here to find out more in our success story. Drive wheels use a hub keyway and key to connect the wheel to the axle. This connection is also used for hub fitting wheels. Hub fitting wheels are also used to drive machinery and vehicles.

Request for a quote

NOVELTY STEEL

Turkey

Belt Conveyor systems consist of several key components with each playing a crucial role in the conveyor’s operation and efficiency. Novelty Steel supplies; *Belt (Belt Carcass) *Conveyor Idlers ( Rollers) *Pulleys *Drives *Other Components

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PU V-belts run individually or alongside one another and convey products on slightly ascending or descending conveying systems without allowing the products being transported, e.g. boxes, tiles, glass slabs, cardboard articles etc., to slip. In addition, PU V-belts are used for driving live roller conveyors. Standard stock program: 75° Sh.A red 80° Sh.A transparent, FDA 80° Sh.A sky-blue, FDA 85° Sh.A green 90° Sh.A white Profiles 6x4 / 8x5 / 10x6 / 13x8 / 17x11 / 22x14 Smooth or notched

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G1 series (with closed impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern on roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. * Suitable for flow rates up to 30 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G2 series (with open impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern with roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. *Suitable for flow rates up to 80 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Robust version for workshops, test-beds etc. Suitable for hose rollers, drive-over proof, long-term loading up to 160°C, short-term to 190°C. Anti-kink finish due to plastic spiral with very good bending characteristics. Construction: Black EPDM tube Fabric inlays Embedded PA-Helix Black cover Interior smooth, exterior rectangular or round and ribbed coupling both ends In fixed lengths with cuffed ends and/or widened hose endings. Other versions and dimensions on request.

Request for a quote

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGAGER, UNIPESSOAL, LDA

Portugal

Powerful and compact, great for MIG welding The Powertec 305C was designed around the need to satisfy our customers' demand for robust and robust compact MIG welders. Built as a true all-rounder, ideal for both thin sheet metal applications and light to medium construction work . Excellent start-up performance. Multi-step voltage knobs for precise adjustment. Excellent drive system with transmission roller Electronic feedback system on the wire drive ensures a constant wire feed speed. Equipped with large diameter wheels, push/pull bar and lifting eyes for total manoeuvrability. Meets IEC974-1, ROHS and CE standards for safety and reliability.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Bester 305C welding machine Lincoln AR/CO2 Regulator/ Flowmeter 30L LE Lincoln Electric LGS3 250 G MIG Torch - Air Cooled - 4M Lincoln Electric 305C It is truly a multi-purpose model, ideal for thin sheet and lightweight applications for medium fabrication work. Powerful and compact, excellent for MIG welding The Powertec 305C was designed around the need to satisfy our customers' demand for robust and robust compact MIG welders. Built as a truly multipurpose model, ideal for both thin sheet metal applications and light to medium construction work. Excellent starting performance. Multi-step voltage knobs for precise adjustment. Excellent drive system with transmission roller Electronic feedback system in the wire drive guarantees a constant wire feed speed. Equipped with large diameter wheels, push/pull bar and lifting eyes for total maneuverability. Meets IEC974-1, ROHS and CE standards for safety and reliability.

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

WM300 Warping Machine The yarn warping machine is applicable to each kind of yarn. Warping can be effected on one of beams at a time special attachments guarantee a perfect uniformity of tension of all ends from the beginning to the end of the warping operation. In fact, the warping angle is held constant and the pressure between the drive roller and the beam is brought about by a air pressure between the drive roller and the beam is brought about by a air pressure system, permitting a varia... WM300 Warping Machine The yarn warping machine is applicable to each kind of yarn. Warping can be effected on one of beams at a time special attachments guarantee a perfect uniformity of tension of all ends from the beginning to the end of the warping operation.

Request for a quote

COMERC SP. Z O.O.

Poland

Belt conveyors(also sometimes called conveyor belts) are widely used in industry (as part of various production lines), logistics (equipment for warehouses and sorting plants), construction, trade, etc. Belt conveyors are designed for horizontal transport of various bulk materials such as pellets, sawdust, wood dust, wood chips etc. They are used as devices for loading and unloading silos (just like other types of our conveyors such as chain conveyors). Depending on the requirements and purpose, belt conveyors could work with capacities from 25 m3/h to 250 m3/h. Belt conveyors consist of drive section, tension section and intermediate sections. The number of intermediate sections depends on its length. Conveyors are equipped with multi-layer conveyor belt, driven by drive section and moving on rollers. Conveyor housing is made of structural steel with Magnelis® coating. Width of conveyor depends on required capacity.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

General-purpose offset printing system for cold plastic tubing and hoses as well as plastic insulated cables including products with irregular surfaces. General pupose printer Indirect printing system Marking speeds up to 150 m / minute Marking cold plastic tubing and hoses as well as plastic insulated cables including products with irregular surfaces STANDARD CONFIGURATION Frame with support column and height adjustment crank mechanism. Marking unit with one marking station, guide rollers, and drive wheel. Complete marking station with ink tank, solvent feed unit, printing disc shaft, and rubber faced transfer roll. 1 set jof dedicated ink wipers and guide roller matching the specified printing disc. Complete accessories kit without printing discs.Offset printing machine with laser engraved steel printing disc and rubber faced transfer roll Also suited for flexo printing using rubber plates (available separately)

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Transport and drive rollers must provide precise transport of the print media in the digital printing process. This is especially true for wide format inkjet printers. Tracking lines, artifacts on the printout, or paper feeding failures are not accepted by the end-user. Our transport rollers are subject to the highest quality standards in respect to: Perfect, defect-free surfaces Precisely defined surface roughness High friction stability over life Tight tolerances in all dimensions

Request for a quote

KRAUS BETRIEBSAUSSTATTUNG UND FÖRDERTECHNIK GMBH

Austria

Power-driven conveyor rollers are used with round belts, Multi-W belts, toothed belts or chain drives. Power-driven conveyor rollers can be used for goods with a wide range of load-bearing capacities.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Suspension Products Horton Roller Bushings Suspension Product last for hundreds of thousands of miles so they rarely need to be replaced — saving you costly downtime and repair costs. Traditional spring pins and bushings aren't designed to withstand the daily abuses of the road. Roller Bushings from Horton provide a long-term lubrication necessary for a properly maintained suspension system. Now you can eliminate the worry of seized pins and front wheel hop. Benefits - Smoother ride - Improved handling - Less chassis stress - Trouble-free solution Features - Special ribbed casing for easier installation - Patented needle bearings provide maximum lubrication - Dual lip seals keep dirt out Links - Order or View Literature - Roller Bushings Suspension Product Catalog

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

THE EFFICIENT SOLUTION FOR SMALL PRODUCTION SERIESAre you looking for a solution that is a more economical choice than a larger Trowal system? Then look no further than our E5 mini barrel. It is perfect for deburring and abrasion, above all on small workpieces from the optical and fine mechanics industries. The double-conically shaped rotating barrel body generates an intense rotation to achieve the perfect abrasion result. SOPHISTICATED TECHNOLOGY The mini barrel stands on a steel sheet construction with four pedestals. The barrel bodies are secured to a drive roller and support roller with locking rings. The barrel body is made from polyurethane and the quick-action cap is waterproof. SPECIAL EQUIPMENT It is also possible to attach two additional barrel bodies if necessary. These are driven via a roller system that is fully variable thanks to a three-phase motor. The cover can also be ordered with safety switches.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Precision Transmission Chains from iwis:Roller chains / Transmission chains

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

KOMAX HOLDING AG

Switzerland

The Kappa 331 is a modular cut and strip machine with a rotating blade module. Round, multilayered cables – with and without shielding – are precisely stripped in multiple steps. The machine can be changed over quickly, making it ideal for flexible use. The Kappa 331 automatic cut and strip machine is used for round conductors with a cross section of 0.22 to 35 mm² (AWG23 – AWG2) and for specific applications up to 50 mm². It performs full and partial pull-off operations on individual layers and strips the outer jackets from jacketed cables with outside diameters of up to 16 mm that are with or without shielding. The high efficiency results from the flexible configuration possibilities and the short conversion times. The Kappa 331 is ideal for work environments with highly diverse products made in large and small batches. Powerful belt or roller drives transmit forces in an optimum way for the widest various of jackets.

Request for a quoteResults for

Drive roller - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Metal straightening machines (6)

- Conveyor belts (2)

- Conveyor systems (2)

- Goods handling systems, continuous (2)

- Harvesting machinery and equipment (2)

- Pumps (2)

- Shearing machine tools (2)

- Cylinders, hydraulic (1)

- Fabric printing - machinery and equipment (1)

- Internal transport systems (1)

- Labelling machines (1)

- Machine tools, cutting - parts and accessories (1)

- Mechanical surface treatment - machinery (1)

- Mechanical transmission systems and components (1)

- Motor mechanics - hand tools, non power (1)

- Needles, industrial (1)

- Pneumatic conveyor equipment (1)

- Textiles - Machines & Equipment (1)

- Transmission belts (1)

- Transportation chains (1)