- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drilling services

Results for

Drilling services - Import export

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Drilling works in our country started with the establishment of MTA in 1935. With the 1950s, drilling applications started not only in the field of oil extraction, but also in the field of mining and natural resources. After the 1970s, the number of private drilling companies has increased and today it is over 1000. With the development of the drilling industry, the use of plastic injection products has increased. The parts, which are mostly called plastic gaskets and felts, are produced and used as plastic injection. Molds of gaskets made of rubber are also produced within our company and product prints are taken. Rubber and plastic seals etc. belonging to the equipment used in this sector. As AYBERKSAN Kalıp Sanayi, we bring the products together with the end user.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the most popular sectors in the field of Injection Molding and Plastic Injection is the Automotive Sector. In general, the majority of automotive accessories consist of plastic and rubber. This is the most important indicator that injection molds and plastic injection products maintain their value. The markets formed in the global world have almost taken on the nature of domestic markets, and competition between countries has gained momentum. AYBERKSAN Plastic Mold Industry takes the necessary steps one by one, with quality and corporate awareness, for its goals to become a brand in both local and world markets.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Custom gun drilled parts, gun drilled shaft, gun drilling spindle, deep hole drilled parts

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

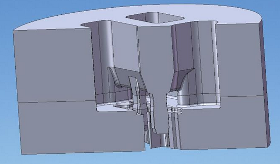

Milling on a 5-axis machine with product dimensions: X=7100mm Y=2400mm Z=1500mm within tolerance of +/-0.02mm. Products are measured using a 3D measuring probe. Machining simulations are done in MasterCam program. We process various materials such as aluminum, steel, and plastic. Milling on 3-axis machines with product dimensions: X=2000mm Y=1000mm Z=550mm within tolerance of +/-0.01mm. Product control is done via Ranishaw measuring system. The system allows for quick control, precise adjustment, and, above all, high quality. Milling on a horizontal milling-boring machine with product dimensions: X=2810mm Y=1920mm Z=2000mm within tolerance of +/-0.02mm. Processing combines milling and drilling on a machine with a rotary table measuring 1800x2000mm and a load capacity of 10 tons.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALUMAX

Greece

Alumax, also, offers final parts of a high quality level in competitive prices. We produce medium and even small batch size components, at short lead times, using our customer’s own drawings or samples. For this purpose, we have invested in modern machinery, such as CNC milling machines, sawing centers and punching & drilling center. Sawing Drilling Milling (from small parts up to 6m bars) Turning (up to a diameter 250mm and a length 800mm) Laser cutting Shearing Forming Punching Laser engraving The above processes, if appropriate, are followed by joining the parts together or with glass, plastic, etc., by welding, bolting, riveting or binding with adhesives.

Request for a quote

ALUMAX

Greece

Alumax uses its experience, which is based on the realization of a large number of special aluminium products on behalf of large European companies. Our qualified working team will inform you about any possible improvements, which limit the costs and lead to the best productive and qualitative result. Our knowledge in the entire range of activities – definition of quality standards, appropriate materials and equipment, extrusion, powder coating or anodizing, required controls and tests – enable us to design and complete your projects effectively. We emphasize in the critical phases (tooling manufacturing, prototypes production and tests), we monitor closely the production procedures and we can guarantee short lead times. Our aim is the development of a creative and long-lasting cooperation with our customers, by offering products of high quality level, on time and at inexpensive prices.

Request for a quoteResults for

Drilling services - Import exportNumber of results

8 ProductsCountries

Company type