- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drill supports

Results for

Drill supports - Import export

AZ MACHINERY

France

3 manual dock levelers with gas cylinder compensation Pre-drilled support legs, integrated dock bumpers. Side safety rails, height: 1.20 m, removable Anti-slip running surface in hot-dip galvanized grating.

Request for a quote

AZ MACHINERY

France

3 manual dock levelers with gas cylinder compensation Pre-drilled support legs, integrated dock bumpers. Side safety rails, height: 1.20 m, removable Anti-slip running surface in hot-dip galvanized grating

Request for a quote

AZ MACHINERY

France

loading ramp with integrated hydraulic dock. Brand: AZ RAMP- Type: FORMATION 2020 ADJ- 10T-ZR-STV Rated Capacity: 10,000 Kg Dimensions: Overall length: 16.18 m Overall Width: 2.22 m - Useful Width (Inside): 1.94 m Length Inclined plane / Inclined part: 6.60 m Length Height Flat-shaped horizontal: 1.10 m Integrated Hydraulic Leveling Wharf (Power Supply 220 V- 50 Hz) Lifting Height: Min: 0.60 m - Max: 1.55 m Support feet, 2 integrated dock stops with refuge zone of 500 mm. Side safety rails, height: 1.20 m, removable Non-slip bearing surface, and hot-dip galvanized Pre-drilled support legs

Request for a quote

AZ MACHINERY

France

Brand: AZ RAMP- Type: FORMATION 2020 ADJ- 8T-ZR-STV Rated Capacity: 8,000 Kg Dimensions: Overall length: 16.18 m Overall Width: 2.22 m - Useful Width (Inside): 1.94 m Length Inclined plane / Inclined part: 6.60 m Length Height Flat-shaped horizontal: 1.10 m Integrated Hydraulic Leveling Wharf (Power Supply 220 V- 50 Hz) Lifting Height: Min: 0.60 m - Max: 1.55 m Support feet, 2 integrated dock stops with refuge zone of 500 mm. Side safety rails, height: 1.20 m, removable Non-slip bearing surface, and hot-dip galvanized Pre-drilled support legs The + Product: specially designed for forklift school. Designed for use with self-mounted trans-pallet, 3 and 4-wheel forklift. Vertical platform of 45.64 m² to turn around with a trolley type 3 electric wheels

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

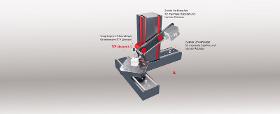

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

Balancers for Rotors of Turbines is one of CIMAT’s horizontal balancing machines. Main features universally applicable custom design for every customer permanent calibration and rotor specific calibration as standard intuitive and easy to operate software latest measuring and control unit ROTORTEST based on microprocessor technology different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed. The greatest advantage of these machines is their versatile application. With this machine different rotors could be balanced, such as discshaped, rotors with own journals as well as blowers, turbines, and many others. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, Onsite drilling units are available, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed for rotors of pumps of different size. The greatest advantage of these machines is their versatile application. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant.

Request for a quote

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special automatic (or manual) collet adapters with the highest clamping repeatability. Compensation of unbalance caused by eccentricity of adapter clamping. We’ve made component marking obsolete—our machines use the latest rotating speed measuring systems. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request. Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690)compliant. Permanent calibration and rotor specific calibration as standard. Intuitive and easy to operate software. Latest measuring and control unit ROTORTEST based on microprocessor technology. Different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights.

Request for a quote

CIMAT

Poland

Balancing machines on a bed for electric armatures. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quoteResults for

Drill supports - Import exportNumber of results

11 ProductsCountries

Company type