- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- draining wells

Results for

Draining wells - Import export

BELLUNO PLAST S.R.L.

Italy

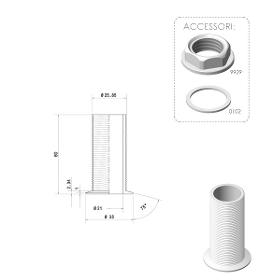

Suitable for draining water and condensate. It is supplied with or without the fixing ring nut code 9929 and on request with: sealing gasket code 0102.

Request for a quote

BELLUNO PLAST S.R.L.

Italy

It is supplied with or without fixing ring nut code 9924 and on request with: closing cap code 9912 sealing cap code 9912/S sealing gasket code 0101

Request for a quote

EXOTIC WHIP

Malta

And finally, a modern take on an old recipe; familiar to most grandparents. With this espuma of eggnog, you show the older guard that not everything used to be better. 300ml eggnog 200ml cream Cream charger Whipped cream siphon Beat the eggnog and cream together until smooth. Add this mixture to the whipped cream syringe and put it to rest in the refrigerator. Before serving the eggnog, it is important to shake the whipped cream syringe well to keep the liquids well mixed. Drain two whipped cream cartridges into the whipped cream syringe so it can be served with the right pressure and right airiness. Paired with a good cup of coffee and a regional cookie, this is the perfect afternoon snack. If you want to make the process of some of these recipes a little easier, you can use our unique cream charger in combination with our taste beads. You can simply insert the taste beads into the cream charger and add exotic flavors to any dish.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

An especially large system with six pumps and a tank content of 26.0 m3, a system power of 800 m3/h and a weight of approx. 6.3 t can reliably handle drainage for a city with up to 37,000 residents. The unique pump controls achieve a discharge head of 40 mWS, while the AWALIFT 10/6x2 version boosts this discharge head to 80 mWS. Proven components, such as our separator, separating flaps, level controller, etc. are used in this system as well. Draining towns with up to about 37,000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with six separator systems Six centrifugal pumps and motors according to type and operating location required Twelve pump gate valves Six STRATE non-return valves One Y-pipe DN 300

Request for a quote

BS ATHLETICS

Turkey

The sandwich system is a cutting-edge technology that has revolutionized the world of athletics tracks. It represents a significant advancement in track construction, offering a range of benefits that enhance performance, durability, and safety for athletes. 1. Layered Construction: The sandwich system is so named because it consists of multiple layers stacked on top of one another, similar to a sandwich. These layers are carefully engineered to provide a combination of qualities that optimize the track’s performance. 2. Base Layer: At the very bottom of the sandwich system lies the base layer. This layer is typically made of asphalt or concrete and serves as the foundational support for the entire track. It provides stability and ensures that the track surface remains level and well-drained.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LEWIS WORLD TRADE SL

Spain

Long Life Deep-frying oil is a special mix of different types of edible oils specifically blended for long life requirements. It is characterized by its long life, contains no trans fatty acids and is cholesterol free. The oil is liquid at room temperature and can be put directly into the fryer. It drains off very well and gives a crispiness to your fried foods.This all-purpose deep-frying oil is very profitable in use and therefore highly efficient for restaurants, fast-food chains and catering establishments.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The injector-glass-blasting cabin is operated by hand with a gun. A blast-collecting collector ensures a smooth blasting circuit within the system. With the help of roller rails, as well as through-slots (on the side and in the roof surface with special brushes against the penetration of dust), surface treatment of glass panes is easy. On the front side there is an easy-open loading door for radiating hollow glass bodies. A work grate and two shock-proof long-field lamps (for glare-free illumination of the blasting chamber) guarantee a smooth workflow. The foot switch as well as the drain cup on the blasting agent funnel, an attached control box with pressure reducing valve and pressure gauge, motor protection switch, on / off button, solenoid valve, control lights, switches for interior lighting, main switch, emergency stop switch and support control ensure uncomplicated operation.

Request for a quoteResults for

Draining wells - Import exportNumber of results

8 ProductsCompany type