- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dewatering screen

Results for

Dewatering screen - Import export

NOVELTY STEEL

Turkey

Various minerals are found in nature either in a dispersed state, where they exist as separate entities, such as native gold particles in silica rock, or in a combined form, where they are bound within a host rock. Dry material separations using screens and sieves are typically attempted down to particle sizes of about 75 microns. Finer materials have a tendency to block the sieve openings. In such cases, screening in the presence of water can be helpful. Separating even finer-sized materials becomes challenging using traditional sieves. For such fine materials, alternative processes like classification need to be employed. Screen Types: * Grizzly Screens * Inclined Vibrating Screens * Horizontal Vibrating Screens * Dewatering Vibrating Screens Novelty Structures supplies various type of Screens for Mineral Processing Plants.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A dewatering screen is an apparatus primarily used in mining, aggregate processing, and recycling industries for ridding water from sand, gravel, and other solid materials. This becomes necessary in removing water from a substance to reduce the moisture content so that it can be handled and transported with ease, processed further, or even possibly stored. It operates on high-frequency vibrations, which drive out the water from the screens, leaving the solid material at the surface of the screens. The material is conveyed along the vibrating screen deck and the expelled water separates away, leaving a drier, more manageable product in its wake.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Dewatering screens are designed as linear vibrating devises for drainage of sand, plastic granules, kieserite, limestone, etc., even to depart insoluble contaminants from wash water or carrier liquids. Advantages & benefits double, specific screening performance of linear vibration with respect to flat screening easy replacement of screen decks low height Construction The design of the screen, depending on the requirements, in single or multi-deck construction. Possible drives are magnetic vibrators, unbalanced motors, exciters and circular vibrators. Dewatering screens are generally designed with top-mounted drives. Selection The sizing depends on: the material to be drained properties of the bulk material, such as bulk density, grain shape, size, size distinction Key figures The dimensions are determined by the task. Previously executed dimensions: length: up to 5,000 mm width: up to 2,800 mm throughput: up to 200 m³/h drives: magnetic vibrator, unbalanced motor, exci

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating Circular motion screens divide into several bulk grain size ranges, seven small amounts of over-or undersize or separate from impurities and foreign matter from the screenings. Vibrating screens are working with directed vibrations/amplitudes, which are selected on special product to screen, depending on the installation conditions. The screens can separate different fractions simultaneously. The choice of the screen size and dimension depend on the task. Advantages & benefits low operating costs, high operational safety, long service life good value for money compact design dust-proof design possible low wear different possible screening performance, depending on size and design different possible meshes and screen shapes possible different possible screen materials (PU, spring steel, stainless steel, wedge-wire screens, perforated plates, etc.) Construction The main components are: strainer with drive traverse strainers / cassette or tensioned version mechanism

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating screens are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or as functional organs to feed belts or crushers. Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three bar grate levels. Each rod is made in a tapered shape which results in a widening gap and bulk jams are avoided. The areas to use such strainers are the primary industry, stones, earth, coal industry with grain sizes up to 1,000 mm in length, but also the chemical and food industry. Everywhere, where a roughly screening and separation of fine and gross material is needed. Advantages & benefits Wide range of applications: product to feed screening of gross grain separation of gross grain before classifying separation of fine grain from crushers protection screening in front of conveyor belts Construction The main components ar

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

PWL static screens provide high operational reliability in the static liquid solid separation for municipal and industrial applications particularly for the separation of fibrous and non-greasy solids. The PWL static screen is very economical and easy to use. The operation of the static screen does without an electric drive or other moving parts. In industrial sewage treatment plants the PWL static screen is known for waste water treatment. Industrial users such as paper mills, food processors, tanneries, laundries, malt houses, breweries, zoos, recycling plants and many other branches rely on the PWL static screen for product recovery and waste water treatment. The curved screen surfaces are basically removable and can be pivoted depending on the width of the static screen. A specially shaped edge at the screen guides the drainage water of the statically dewatered screenings into the discharge trough of the static sieve. Optionally, the PWL static screen can be supplied with a...

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A dewatering screen is an apparatus primarily used in mining, aggregate processing, and recycling industries for ridding water from sand, gravel, and other solid materials. This becomes necessary in removing water from a substance to reduce the moisture content so that it can be handled and transported with ease, processed further, or even possibly stored. It operates on high-frequency vibrations, which drive out the water from the screens, leaving the solid material at the surface of the screens. The material is conveyed along the vibrating screen deck and the expelled water separates away, leaving a drier, more manageable product in its wake. The ability of dewatering screens to perform moisture control is essential for the effectiveness of many industrial processes. Preparing sand for the production of concrete, or ore for further processing after mining, will require guaranteed moisture content of the material.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

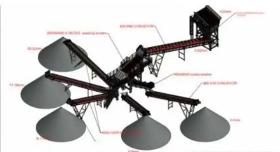

What is a Track Mounted Mobile Washing and Screening System? Track-mounted mobile screening and washing units are adaptable and productive pieces of machinery used in recycling mining and aggregate production. A vast variety of materials including aggregates ores coal and industrial minerals can be screened cleaned dewatered and classified using these units. The mobility of track-mounted mobile screening and washing units is a significant benefit as it facilitates their easy transportation to various job sites. This adaptability lowers the need for multiple machines at different locations while increasing productivity. Furthermore these units are outfitted with cutting-edge features like hydrocyclones vibrating screens and water treatment systems to guarantee peak performance and superior quality of the finished product. All things considered mobile screening and washing-track mounted units which offer effective and affordable solutions for screening and washing operations

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Compact Sand Washing Plants are small, specifically designed plants developed for the effective cleaning and separation of sand particles in industrial applications. Most of the plants consist of a combination of equipment, including a sand washer, dewatering screen, hydrocyclones, and fine material washers, all integrated into one compact and mobile unit. Compact Sand Washing Plants are mainly designed to remove impurities, silt, and contaminants from sand to leave the final product clean, well-graded, and fit for use in construction, concrete production, and other industrial procedures. These plants integrate several washing and screening mechanisms in an integrated compact design, ensuring high effectiveness in washing and dewatering sand while guaranteeing better output quality at space and operationally lower footprints.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Compact Sand Washing Plants are small, specifically designed plants developed for the effective cleaning and separation of sand particles in industrial applications. Most of the plants consist of a combination of equipment, including a sand washer, dewatering screen, hydrocyclones, and fine material washers, all integrated into one compact and mobile unit. Compact Sand Washing Plants are mainly designed to remove impurities, silt, and contaminants from sand to leave the final product clean, well-graded, and fit for use in construction, concrete production, and other industrial procedures. These plants integrate several washing and screening mechanisms in an integrated compact design, ensuring high effectiveness in washing and dewatering sand while guaranteeing better output quality at space and operationally lower footprints.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Track Mounted Mobile Washing and Screening System? Track-mounted mobile screening and washing units are adaptable and productive pieces of machinery used in recycling mining and aggregate production. A vast variety of materials including aggregates ores coal and industrial minerals can be screened cleaned dewatered and classified using these units. The mobility of track-mounted mobile screening and washing units is a significant benefit as it facilitates their easy transportation to various job sites. This adaptability lowers the need for multiple machines at different locations while increasing productivity. Furthermore these units are outfitted with cutting-edge features like hydrocyclones vibrating screens and water treatment systems to guarantee peak performance and superior quality of the finished product.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UMDS series dewatering screens are designed to remove water from the acquired sand in a washing system. After any washing, sand contains a minimum of 20% water. It will be possible to stock up this amount of water and dry it in weeks minumum. However, this increases the inventory cost excessively. For this reason, dewatering screen is very valuable equipment for washing systems.

Request for a quote

KESTASMAK MINING MACHINERY AND SPARE PARTS

Turkey

jaw crushers, primary impact crushers, secondary impact crushers, dewatering systems, screens, vertical shaft impact crushers, VSI, VSI spare parts, crusher wearing parts, feeders, bunkers, conveyor systems, conveyor belts, conveyor rollers, conveyor drums, belts, clamps, high carbon steel woven meshes, anti clogging, anti-clogging screen meshes, flex screens, perforated steel screens, bolts, polyurethane screens, polyurethane tensioned screen panels, polyurethane jig screens, polyurethane dewatering screens

Request for a quoteResults for

Dewatering screen - Import exportNumber of results

14 ProductsCountries

Company type