- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- destruction

Results for

Destruction - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Penetrant non-destructive testing method is a system that is used for the detection of cracks in the surfaces of parts. After the material which is going to be subjected to penetrant test is pre-cleaned, it is subjected to penetrant application as dipping or spray. After this process, the material is rinsed and dried. Powder “developer” is applied electrostatically on the dried material. Finally, possible cracks and faults on the material are detected by checking under the UV lamp.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Applications and projects : integration of non-destructive testing equipment in an industrial environment Some practical examples : dimensional checks tomography 3D vision X-ray

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

With the dual chamber PPM leak test stand, Poppe + Potthoff Maschinenbau offers a powerful system for testing sensors in medical device industry. The test stand can be implemented in R&D processes, but also during production as an end of line test. With pressures of up to 50 bars this equipment offers a large spectrum of testing opportunities in the medical area. Some Global Test Standards include: ISO 14644 ASTM G122-96 ASTM D6361 SAE AMS 0302 The PPM leak test stand is able to be programed to the customers requirement. The powerful in house built software enables exact design of pressure curves, such as holding times and exact pressure increase over time. It is an ideal solution for any sorts of plastic components. This exemplarily displayed test bench can utilize air or nitrogen as a test medium. Please get in touch about any other test mediums. In addition the PPM test benches can perform tests of multiple test units at a time.

Request for a quote

KASAG SWISS AG

Switzerland

Our specialists have vast knowledge and many years of experience in non-destructive testing (NDT) of welding seams, welding constructions, pressure vessels, containers, equipment and plants. We use and offer the following testing procedures for that purpose: X-rays RT Dye penetrant testing PT Visual inspection VT Material testing/ Positive Material Identification PMI Helium leakage testing LT Riboflavin test Pressure tests of up to max. 1000 bar Surface roughness testing Ra/Rz Ferrit measurement Fe Wall thickness measurement Video endoscopy Pressure-loss test (liquid) With KASAG, you remain on the safe side.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

The D-Tect X-ray inspection software is completely developed by DÜRR NDT and is the perfect complement to all digital X-ray systems like imaging plate scanners and flat panel detectors (DDAs). DICONDE compliant The user can be certain that images can be viewed on any other DICONDE compliant system. All-in-one All functions are included: from image acquisition, image evaluation and report generation to data import and export. High performance GPU and multi-core CPU support makes D-Tect X extremely fast and efficient.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust flat-panel detector was specially designed for mobile use and the harsh conditions of industrial radiography and can be used with X-ray and gamma sources. With its active area of 23.0 x 28.8 cm, excellent contrast and uniquely high resolution thanks to a pixel pitch of 75 µm, even the most demanding inspection tasks can be mastered. - Weld seam inspection - Pipe inspection, corrosion inspection, erosion inspection - Crack detection - Casting inspection

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

CMOS detector for ultra-high resolution imaging which meets aerospace standards! Ultra-high resolution Brilliant results thanks to 19 μm pixel pitch Time to image Increased productivity through fast processing Compact design Versatile positioning options and universally applicable Most important features Because of its compact design, the detector is ideal for small tubes, and it can also be positioned in hard-to-reach places or even inside an object. In order to provide for efficient performance in a harsh test environment, the detector is equipped with a durable aluminum casing, and its active area of 36x26 mm is protected by a strong carbon layer.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

The one-part NDT X-ray chemistry ensures absolutely brilliant results in industrial film processing and is tried and tested in oil & gas, aviation, nuclear and military applications. As it is free of hazardous substances, it is not subject to any transport restrictions, it is odorless and free of hazardous and carcinogenic ingredients. It can be used universally and is therefore also suitable for mixed systems with different devices and X-ray films.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

DRIVE NDT is a cloud-based management software which integrates all NDT inspection methods and associated processes into a single system. With DRIVE NDT you can organize and control the complete NDT job workflow including individual test reports, staff, customer and device management, and much more. One solution for all NDT inspection methods Radiographic Testing (RT-D, RT-F, CT) Ultrasonic Testing (UT-PA, UT-TOFD, UT-WD) Visual Testing (VT) Electromagnetic Testing (ET) Magnetic Particle Testing (MT) Liquid Penetrant Testing (PT) Acoustic Emission Testing (AT) Acoustic Resonance Testing (ART) Infrared/Thermal Testing (IR/TT) Leak Testing (LT) Optical Methods (OM) ...

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

Extremely robust and waterproof digital detector array (DDA) for the harsh conditions of industrial radiography and maximum portability. High contrast High sensitive GOS scintillator Large format 35 x 43 cm active area, perfect for profile images Portable & ruggedized 7.4 kg / 70 cm drop test pass Important features: • 100 μm pixel pitch (5.0 lp/mm) • Suitable for X-ray and gamma sources • Equipped with internal shielding for use up to 450 kV • Light-weight full size detector • Hot-swap function enables battery change during operation • Built-in wireless access point • Connector for Gigabit Ethernet and power • Dust-tight and waterproof (IP67) • 70 cm drop test pass

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust and waterproof digital detector array (DDA) has been specially developed for maximum portability and the harsh conditions of industrial radiography. High-resolution 76 μm pixel pitch Compact design 10 x 24 cm active area Lightweight & ruggedized 2.2 kg / 1 m drop test pass IMPORTANT FEATURES - Suitable for X-ray and gamma sources - Equipped with an internal shielding for use up to 350 kV - Extremely robust design with detachable carry handle - High resolution 76 μm pixel pitch (6.5 lp/mm) - Built-in wireless access point - Connector for Gigabit Ethernet and power - 1 meter drop test pass - Dust-tight and waterproof (P67) - For stationary and mobile applications

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

Portable high resolution CR scanner for all NDT radiography applications - weld inspection, profile images and aerospace Unique 30 μm basic spatial resolution – BAM-certified Scans flexible imaging plates up to 35 cm in width Widest range of applications thanks to TreFoc Technology Intuitive handling & easy transition from film Portable and compact (17.5 kg) What does TreFoc Technology mean and how does it work? TreFoc Technology is the name for the our new laser focussing technology, uniquely in systems from DÜRR NDT. With TreFoc the laser beam is adjusted perfectly to give optimal image results and the highest signal-to-noise ratio in any application. Inside the laser tube, an iris diaphragm adjusts the laser beam diameter. Since the perfect laser beam diameter can be selected for each object and image type, optimum results for any particular application can be easily achieved. Regardless of the application – high-resolution image or low-exposure c

Request for a quote

TELEDYNE ICM

Belgium

The CP300DM is a constant potential portable generator with a duty cycle of 100% in 30°. Its metal-ceramic tube makes this generator the robust partner you need for your digital radiography inspections. With its high output voltage range (up to 300 kV), the CP300DM has a steel penetration of 66 mm and will adapt to a wide range of NDT applications. Like the other CPSERIES generators, it features a build-in carrousel with 5 output positions and operates with the plug-and-play POWERBOX control unit.

Request for a quote

TELEDYNE ICM

Belgium

The CP300DS is the perfect tool for digital radiography. Its small focal spot generates sharper and clearer images which will enable you to accurately detect the slightest defect during your NDT inspections. With its metal-ceramic tube and its high output voltage range (up to 300 kV), this constant potential portable generator is also a robust partner for a wide range of NDT applications. The CP300DS features our famous build-in carrousel with 5 output positions and has a 100% duty cycle at 30°. It operates with the plug-and-play POWERBOX control unit, like the rest of the CPSERIES product range.

Request for a quote

PEROZENI SRL

Italy

The quality of the welded structures is guaranteed by non-destructive tests carried out on request by our qualified in-house personnel or by certified external organizations. We also perform dimensional tests that, on the basis of the precision required, are made using calibers, micrometers or the special tool “FARO Cam2 Laser Tracker Vantage”. Other types of processing can also be handled by us, such as distension heat treatment, metallic galvanization, chrome plating and other treatments, through our partnership with qualified suppliers with whom we have established advantageous collaboration for many years.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

This magnetic system is specially designed for non-destructive testing of pumped vacuum devices, that required the creation of a uniform magnetic field not only in the center of the operating bore, but in the toroidal region of large size. The system is assembled on the basis of NdFeB permanent magnets.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SONATEST LTD

United Kingdom

Discover our extensive range of UT transducers. Visit our UT webpage for more information: https://sonatest.com/products/transducers For more information on all our transducers, download our latest Transducer Catalogue: https://sonatest.com/transducers/register Sonatest Ltd and Sonatest Inc manufacture and design a complete range of high performance, high technology ultrasonic transducers for general flaw detection and thickness measurement applications. Each transducer is made to exacting standards regarding acoustical, electronic and mechanical properties. Our transducers are tested thoroughly, typically at three stages of manufacture. The complete range of transducer types are available with a variety of connector styles, case configurations, frequencies and element sizes.

Request for a quote

SONATEST LTD

United Kingdom

The WheelProbe 2 64e and 128e have demonstrated unparalleled performance in the realm of composite inspection and corrosion monitoring, excelling in terms of both speed and user-friendliness while consistently delivering outstanding results. Applications where the WheelProbe 2 is currently in use include, aeronautical and astronomical aerospace part inspections, marine hull inspections, corrosion mapping asset integrity inspections in the oil and gas industry, composite inspections in the automotive and structural industries and many more.

Request for a quote

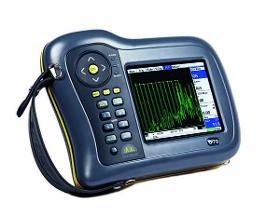

SONATEST LTD

United Kingdom

The Masterscan D-70 offers the inspector a fully capable and functional set of tools and software for inspection across all applications. Capabilities include encoded B-Scan, Advanced Thickness logging and Dryscan capability in a portable enclosure. Features Include: Customisable & Inituitive Menus Split DAC/AVG/DGS Angle Measurement Mode. Dryscan capability. Configurable on-board software. Field Upgradeable. Encoded B-Scan A-Scan Fade. 4GByte on-board memory. USB Interface for PC import/export. Video Output for training.

Request for a quote

SONATEST LTD

United Kingdom

The Sitescan 500S offers the end user an entry level broad band flaw detector with a full VGA display, sync and proportional outputs and a 50nS 200V Pulser. Customisable & Inituitive Menus Split DAC/AVG/DGS Angle Measurement Mode. Configurable on-board software. Field Upgradeable. Encoded B-Scan A-Scan Fade. 4GByte on-board memory. USB Interface for PC import/export. Video Output for training.

Request for a quote

SONATEST LTD

United Kingdom

The Sonatest AlphaGage+ series is definitely a key asset for inspectors, maintenance operators or QA technicians looking to measure essentially any engineering material thickness as it combines years of ultrasonic design and knowhow. Packaged in an extremely rugged and ergonomic hand held enclosure, the AlphaGage+ is a versatile piece of equipment as it can be used to perform integrity assessment of metal steel works affected by erosion or corrosion processes as well as measure precisely the thickness of critical pieces of equipment which have very strict quality control requirements.

Request for a quote

SONATEST LTD

United Kingdom

Retaining the best features of the established Veo line, the new Veo3 now offers a PCAP touch interface, user templates, and more importantly, live TFM. Key design elements of the Veo3 are user and performance focused. Based on superior and innovative digital technology and its live concurrent multi-scan / multi-technique capabilities, the Veo3 truly helps you to inspect with confidence. The Veo3 multi-techniques allow inspectors to keep inspecting as they always have, with no need to change their current workflow and by doing so, users can benefit from the additional resolution and sizing performance of TFM while carrying out an already approved, trusted and reliable procedure.

Request for a quote

SONATEST LTD

United Kingdom

Discover our extensive range of Phased Array transducers. Visit our Phased array webpage for more information: https://sonatest.com/products/phased-array For more information on all our transducers, download our latest Transducer Catalogue: https://sonatest.com/transducers/register Sonatest Ltd and Sonatest Inc manufacture and design a complete range of high performance, high technology ultrasonic transducers for general flaw detection and thickness measurement applications. Each transducer is made to exacting standards regarding acoustical, electronic and mechanical properties. Our transducers are tested thoroughly, typically at three stages of manufacture. The complete range of transducer types are available with a variety of connector styles, case configurations, frequencies and element sizes.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

JME LTD

United Kingdom

JME portable Betatron systems are a range of compact circular electron accelerators producing a high energy directional X-Ray beam. The Betatron systems are easy to assemble, operate and maintain. They contain no moving parts or cooling liquids so maintenance required on the systems is minimal. They are capable of producing radiographs of very high contrast, sensitivity and resolution allowing operators to meet the tightest inspection standard. JME offer 4 systems within the Betatron range each with a different maximum energy, the outputs are 2.5, 6, 7, 7.5 and 9MeV. The energy output on all systems is variable from 2Mev through to the maximum energy and adjustments can be made in 0.1MeV increments. The systems offer cost savings and a greater degree of portability when compared with systems such as linear accelerators (Linacs) which are much larger, non-portable, and can cost up to 10 times the price of a JME Betatron.

Request for a quote

JME LTD

United Kingdom

JME Advanced Inspection Systems has a reputation as the market leader for the design and manufacture of high quality inspection systems, this includes our range of Pipeline Crawlers used by the ‘Non-Destructive Testing’ industry. For over 30 years, JME Pipelines Crawlers have been continually improved and updated to produce panoramic radiographs of the highest quality. Our range of systems are designed to inspect circumferential butt welds in new pipelines, such as oil and gas transmission pipelines, from 6” to 72” (15.24cm to 183cm). As a self-contained and self-powered exposure vehicle, they are ideal for a vast range of NDT applications both on and off shore. Over the past 30 years, JME has built its reputation on innovation, quality, service, and commitment to our clients. As a company, JME thrives on customer satisfaction, which is why many of our customers have been using our services for nearly 30 years.

Request for a quote

NOVOSOUND LTD

United Kingdom

A non-invasive, compact ultrasound sensor for the continuous monitoring of corrosion and erosion. With its low-profile size and flexibility, the Belenus can be fitted to a range of structures including pipes, storage tanks and pressure vessels, enabling 24/7 asset monitoring. Suitable for fixed installation in both extreme and ambient environments, the Belenus is the world’s first corrosion monitoring sensor that can operate completely soaked in high-temperature atmospheres up to 400°C (752°F) for extended periods of time. The Belenus provides real-time, asset integrity data, enabling operators to proactively manage corrosion risk, make data-informed decisions and reduce the overall cost of operations. Via a cloud-based system, the Novosound Nebula, plant operators can access inspection data remotely - anytime, anywhere. This allows analysis of key asset integrity data across a range of locations, informing key operational decisions.

Request for a quote

NOVOSOUND LTD

United Kingdom

Representing a breakthrough in ultrasonic inspection, the Kelpie’s unique flexibility and low-profile form (0.5mm) allows it to flex, twist and bend during scanning, conforming to difficult shapes and surfaces. Designed for detecting flaws such as cracks and voids in metals and composites, the Kelpie can wrap around small-diameter piping, scan uneven surfaces and bend round elbow joints with unparalleled precision and accuracy. With enhanced surface conformance, the Kelpie is a market-leading tool for corrosion mapping of critical assets – achieving increased scan speed and enhanced imaging. Put the Kelpie to the test with an Evaluation Kit. Easy, accessible and exciting to use, the kit enables users to assess, calibrate and test the Kelpie for a specific application. If you’re looking for a unique solution to fit your requirements, we can help. With a range of customisable parameters including frequency, pitch, kerf and form, the Kelpie can be transformed to fit your application.

Request for a quoteResults for

Destruction - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Non-destructive tests (20)

- Electricity generators (3)

- Mechanical engineering - custom work (2)

- Radiology equipment, industrial (2)

- Cutting - machine tools (1)

- Lasers - medical applications (1)

- Magnetic equipment (1)

- Motor mechanics - hand tools, non power (1)

- Paint spray guns and accessories (1)

- Production and operational inspection (1)

- Software (1)

- Supply vessels (1)

- Testing equipment (1)