- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- design of hydraulic systems

Results for

Design of hydraulic systems - Import export

HII

Turkey

Sandwich panel press Sandwich Panel Production Line Our contionuous PUR / PIR sandwich panel production line is already recognized its value by exporting to European country with CE and other major sandwich panel producing companies at domestic and foreign, DMMET, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels. APPLICATION of the PU-PIR PANEL PRODUCTION LINE This production line is suitable for manufacturing socket type ( wall plate panel ) and lapped type ( roof tile panel ) pu sandwich panels. FLOW CHART Uncoiler - Feeding Guide - Protective Film Coating - Roll Forming Machine - Rolling Conveyer - Steel Pre-Heating - Foaming Machine - Double Belt Pressing Machine - Rolling Conveyer - Auto Fly Cutting To Length - Runout Table - Auto Vacuum Stacker - Auto Packing Machine MAIN TECHNICAL DATAS Production Type : Continuous and automatic production Specification of Metarial : 0.3 - 0.

Request for a quote

ALS HYDRAULIC

Turkey

We have power units at difference dimensions and features

Request for a quote

BDSENSORS GMBH

Germany

The industrial pressure transmitter DMP 334 has been especially designed for use in hydraulic systems up to 2200 bar. The base element of DMP 334 is a thinfilm sensor, that is welded with the pressure port and meets high demands of foolproofness and reliability. All of characteristics and the excellent mesurement data of DMP 334 as well as distinguished offset stability offer a pressure transmiter with easy handling, reliability and robustness for hydraulic user. The DMP 334 is deliverable with pressure ports of extrem pressure technics. Features: — nominal pressure: 0 ... 600 bar up to 0 ... 2.200 bar — accuracy: 0.35 % FSO — pressure sensor welded — extremly robust and excellent longterm stability Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts — pressure port M20 x 1.5 oder 9/16 UNF — adjustability of span and offset — different kinds of electrical connections

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Food Grade Hydraulic Fluids are lubricants designed for use in hydraulic systems within food processing facilities, where there may be occasional contact with food. They are also suitable for application in the maintenance of bearings, chains, and valves in canning and bottling equipment. These specialized fluids are formulated using synthetic hydrocarbons known as Poly Alpha Olefins, combined with carefully crafted additive blends. This unique composition ensures exceptional wear resistance, temperature stability, and safeguards against the accumulation of varnish and deposits.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The Oil Condition Sensor OCS is designed for continuous monitoring of hydraulic systems. Permanently installed in the system the OCS sensor monitors the condition of hydraulic fluids and lubricating oils in real time, whereby water ingress and oxidation can be detected in time. The OCS sensor is 60 times more sensitive than dielectric sensors on increasing contamination and protects the system from cost-intensive downtimes and reduces machine downtimes. Thanks to its robust construction the OCS sensor can even be used under extreme conditions and temperatures. ▪ Robust construction ▪ ƒƒUsage under extreme conditions with temperatures from -20 °C ... +120 °C /-4 °F ... +248 °F ▪ ƒƒSuitable for use at operating pressures up to 20 bar / 290 PSI Materials ▪ ƒƒStainless Steel (corrosion-resistant Steel) AISI304, 1.4301. Dimensions ▪ ƒƒ90 x 37 mm / 3.54 x 1.46 in Weight ▪ ƒƒ160 g / .35 lbs Sealing Material ▪ FPM (Viton®) Max. Burst Pressure ▪ 20 bar / 290 PSI Media Temperature ▪ -20 °C...

Request for a quote

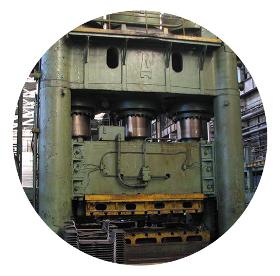

SIMPAC EUROPE GMBH

Germany

Hydraulic presses are suitable for the high-precision forming of various parts, whereby the maximum press capacity is available in every position of the slide. In combination with their flexibility in terms of slide speed and dwell time, they are also particularly suitable for press hardening applications. Overview: ● Press capacity: 1,500 - 25,000 kN ● Part size: small, medium, large ● Application: for the production of drawn parts or as part of a press hardening line Description and benefits: ● Slide movement either pressure and / or travel-dependent ● Specially designed hydraulic system without shift shock during operation ● Motorized oil circulation with cooling or heating unit The models for press hardening are available in 8,000, 12,000 or 16,000 kN and come with a newly developed combination of servomotor and hydraulics that allows higher speeds in the closing and return movement of the slide.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling timber, stacked wood, etc., for downstream industries, in sea and inland ports or at storage facilities. For ship-to-ship, ship-to-storage/wagon/lorry handling. For various types of crane with control systems designed for hydraulic grab systems. Technical design Designed to grip stacked wood, with two interlocking shells to grip one or several logs Optimisation of crane load capacity thanks to its lightweight design which can grip maximum amounts Slim shell design for optimal penetration Wear-resistant cutting edges The hydraulic system’s dimensions, short open and close times and high closing pressure guarantee the quick grab and secure hold of the logs Protected and easily accessible inbuilt electro-hydraulic propulsion motor Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Designed as a discharge and ship unloading grab with retracted pivot bearings for easy gripping under the ship’s gangway Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab connection bearing: Re-greaseable steel bushing bearing Stable, torsion-resistant design using direct cylinder linkage

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, car bodies, steel chips, shredder scrap, paving stones and much more, in sea and inland ports or at storage facilities. For pier engineering and riverbed maintenance. For various types of cranes and excavators with internal or external holding cables. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Open, half-closed or closed grip design Suitable for handling scrap, stones, waste and other difficult to grab goods depending on design Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads, self-locking grab suspension for crane hooks Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab connection bearing:

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. The compact alternative to the MZG type grab for ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Designed as a discharge and ship unloading grab with retracted pivot bearings for easy grab under the ship’s gangway Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Self-locking grab suspension for crane hooks Grab drive: Horizontal electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab shells: Material: S355J2+N Grab connection bearing: re-greaseable, robust steel bushing bearing Small grab dimensions thanks

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC rotary table SKV-NC2 - worm drive, i=72 - safe transport load vertical 200 kg, horizontal 700 kg, with counter bearing 400 kg - table plate Ø 250 mm - vertical/horizontal use - construction design: continuous rotary table with hydraulic clamping system - max. table plate speed: 41 rpm at motor n=3,000 rpm - safe axial load : vertical 7,500 N, horizontal 24,000 N - safe radial load: vertical 7,500 N, horizontal 24,000 N

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KW HYDRAULIK GMBH

Germany

Cable cutting unit in several sizes for cutting cables, in case of failure under voltage.

Request for a quote

MCS HYDRAULIC&PNEUMATIC

Turkey

We have every type of hydraulic fittings.

Request for a quote

MCS HYDRAULIC&PNEUMATIC

Turkey

We have power units at difference dimensions and features.

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Hydraulic power units are produced in close cooperation with customers. Highly-qualified technical and commercial marketing staff are continually working to meet the needs and wishes of our customers and their problems from the field of hydraulics. Gidrolast offers our customers knowledge, expertise and experience in solving such problems. Gidrolast engineering knowledge is a core competence of projecting processes. In this process, our engineers design hydraulic power units to customer requirements, all necessary documentation is prepared and risks and production capabilities are assessed and the whole project is prepared for execution. In the sales process, the customer gets a full quotation. The whole process of monitoring the execution of customer’s order is carried out by the business information power unit. In order to delivery process the hydraulic power unit is produced, tested, adjusted and prepared for transport on the basis of technical documentation.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast knows heavy trucks. We cut our teeth building hydraulic cylinders for heavy trucks all the way back in 1993. Hydraulic cylinders on trucks are subjected to all forms of contamination that would destroy a poorly designed cylinder. Dirt, grit, rain, salt, tar, chemicals, solvents and cleaning agents all combine to attack the cylinder and its seals. Despite all this, the cylinders are still expected to perform. Cylinder failure means downtime, employee overtime, loss of vehicle availability, less productivity and reduced profit. Gidrolast cylinders are built tough to meet these conditions. They can be found mounted on garbage trucks, dump trucks, belly dumpers, semi end dumpers, boom trucks, knuckle boom loaders, road pavers, concrete mixers, concrete pumps, mobile cranes, tilt beds and tow trucks. Applications include dump cylinders, aerial boom cylinders, compaction cylinders, outrigger cylinders, tilt cylinders, swing cylinders, plough lift cylinders, and more.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast got its start in building rugged hydraulic cylinders for use on heavy trucks in the waste management industry way back in 1994. That means we know first-hand what is required to build cylinders that will tough it out in this industry. So whether the cylinder is operating the gate on a garbage truck or the grapple in a scrap metal yard, the compactor on a scrap baler or lifting the blade of a bulldozer in a land fill site, Gidrolast cylinders are built to last. Both OEMs and end users around the world appreciate the rugged reliability built into each of our cylinders. Careful, experienced design is combined with high-quality manufacturing to make our Gidrolast hydraulic cylinders the cylinders of choice in waste management and recycling equipment. It’s not hard to see why tough, reliable cylinders are required in the waste management and recycling industry, as these pictures clearly testify. Hydraulic cylinders are shown in action in a scrap metal yard above.

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

Special units 1000 to 50000 liter tank volumes, standard aggregates, motor / pump assemblies, valve stands, storage stations, filter cooling circuits, lubrication systems, engineering and delivery compl. tube sets

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

Our standard range was developed with regard to technical and economic aspects especially for the increased requirements in machine and plant manufacturing. Steel and aluminum manifolds, adapter, blind and intermediate measurement plates are in stock at any time, allowing us to quickly meet your urgent requirements for various pressure stages. All plates have corrosion protection (zinc-plated or anodized).

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quote

HYDRAULIK SCHWERIN GMBH

Germany

design, manufacture and assembly of hydraulic control blocks in single part and series production

Request for a quoteResults for

Design of hydraulic systems - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Hydraulics systems (12)

- Hydraulic equipment (4)

- Pumps, hydraulic (2)

- Cutting - steels and metals (1)

- Cylinders - combustion engines (1)

- Gear pumps (1)

- Hydraulic tools (1)

- Lubricants for cars (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Metal industrial presses (1)

- Platform hoists (1)

- Press agencies, international (1)

- Stamping - machine tools (1)