- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting fluid

Results for

Cutting fluid - Import export

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Different type of semisynthetic metalworking fluids used for the machining of cast iron, steel, copper, brass and aluminium metals composed of base oil, esters, corrosion inhibitors, EP/AW additives and biocides

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial centrifuge designed for effectively separating metal chips from cutting fluids. The PRAB Metal Chip Wringer/Centrifuge uses 600G’s of centrifugal force to spin fluid from metal chips. This process is the most cost-effective solution for producing dry metal chips—which are more valuable to the scrap dealer. Wringers also help to reclaim up to 98% of spent cutting fluid for recycling and reuse. Metal chip wringers/centrifuges handle various types of metal scrap, including aluminum, brass, cast iron, steel, stainless steel, and more.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

The PRAB ScrapVeyor™ features leak-proof construction that retains 100% of cutting fluids when moving scrap to its destination, and positive discharge provides a clean operation while eliminating carryover. Combine this scrap conveyor with a distribution system to maximize operational load-out efficiency. This fully automated and liquid-tight scrap conveyor with positive discharge provides a clean operation when it comes to die scrap, chip processing and material handling. Combine this scrap conveyor with a distribution system to maximize operational load-out efficiency.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Move or dump more scrap with heavy-duty dumpers and industrial carts. PRAB’s line of industrial carts and automatic dumpers help move wet or dry metal chips, turnings and die scrap, safely and easily to and from scrap metal equipment. Customize the model and capacity cart you need with tow links, dumping frames, pouring baffles (contains cutting fluids), drain plugs, drain racks and casters designed to meet your floor conditions. Mechanical or automatic hydraulic dumpers help simplify the process of unloading carts. Improves housekeeping with efficient one-person operation Minimizes scrap handling costs Reduces production downtime

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

50 lint-free, highly absorbent wipes for cleaning plastic surfaces and screens. • Lint-free, highly absorbent fleece wipes • For cleaning plastic surfaces and screens • Ideal for use with DURABLE cleaning fluids • Cut to size individually in 145 x 197 mm format • Contents: 50 wipes

Request for a quote

F.E.S. GMBH

Germany

Automatic Precoat Filter are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Fully automatic operation Excellent filtration results Compact size Low maintenance requirements Full-flow filtration Dry cake discharge with minimal carryover of cutting fluid No fleece consumption Maximum lifespan of cutting fluid Operating Principle: The cleaned cutting fluid is supplied to the filter system pump (1) from the clean tank (2) of the processing machine. The contaminated cutting fluid is introduced into the dirt tank (3) of the cake filtration system through inlet channels or lifting stations. The internal processing of the system consists of four steps: “Cake Formation,” “Filtration,” “Regeneration,” and “Sludge Treatment.”

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® WORK is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® WORK is stable under extreme condition with low concentrations. Maxant® WORK is suitable for fully-synthetic working fluids and emulsion type working fluids. Permanent foam cut off Rapid foam knock-down Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Excellent foam control Keep the initial performance Shear Stability Maxant® WORK is mainly designed for preventing foam in process applications. Maxant® WORK can be added directly into the foam solution. 1-20ppm is suitable for application.

Request for a quote

LATRO KIMYA DIS TIC A.S.

Turkey

Maxant® WORK is a highly effective silicone antifoam emulsion. It offers excellent foam control and high stability in various foaming systems. Maxant® WORK is stable under extreme condition with low concentrations. Maxant® WORK is suitable for fully-synthetic working fluids and emulsion type working fluids Permanent foam cut off Rapid foam knock-down Long durability in acidic and alkaline conditions Outstanding durability at low add on levels Excellent foam control Keep the initial performance Shear Stability Maxant® WORK is mainly designed for preventing foam in process applications. Maxant® WORK can be added directly into the foam solution. 1-20ppm is suitable for application.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

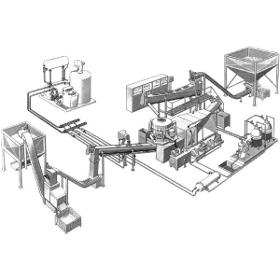

Through the process of briquetting, the value of residual metals can be increased considerably. The value of residual metals can be increased considerably. A further advantage is the recovery of expensive cutting fluids that can be pressed out of wet chips and then reused. When melting briquettes, combustion is significantly lower and results in a higher melting yield than with loose chips. Depending on the need, our briquette systems are equipped with hydraulic motors between 4 and 90 kW. They will achieve a specific pressure of up to 5,000 kg/cm². Suitable for aluminium, steel, cast iron, copper and many other metals Advantages: - Heavy reduction of volume, reducing storage and transportation costs - Recycling of expensive cooling lubricants - Recipients often pay a better price for loose millings - Minimal burn-off and increased glaze recovery thereby For throughput rates between 30 and 4,800 kg/hr.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Soluble Cutting Fluid is a high-quality, chlorine-free cutting oil enriched with borates. It is engineered to excel in light to moderate machining operations, covering a wide range of tasks such as boring, milling, drilling, tapping, threading, broaching, turning, reaming, and grinding. This cutting fluid is known for forming dependable and stable white emulsions with a generous “emulsion reserve.” It showcases remarkable resistance to bacterial degradation, ensuring a longer service life. Importantly, it contains no free phenolics or nitrites. Additionally, it exhibits minimal foaming tendencies when applied in various machining applications, making it a reliable choice for precision operations.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Biocut 3755 Soluble Cutting Fluid is a highly adaptable, all-around, semi-synthetic solution designed for machining and grinding processes. It proves to be effective for a diverse array of metal removal tasks, catering to both ferrous and aluminum alloys.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

RX80 Gear Oil stands as a cutting-edge manual transmission fluid meticulously engineered to deliver smoother gear transitions across a broad spectrum of temperatures. It is compatible with the manual transmissions found in numerous vehicle models from various manufacturers. Notably, RX80 Gear Oil exhibits exceptional adaptability in cold climates. It minimizes the resistance during initial use, while also effectively managing transmission noise and idling vibrations during regular operation. RX80 Gear Oil provides: Reduced transmission noise for quieter operations. Effortless shifting in low temperatures. Enhanced longevity of gear teeth and bearings. Consistent lubrication performance across a wide range of operating temperatures. Exceptional wear resistance, ensuring a strong and protective film throughout the lubricant’s lifespan. Minimal friction in 2-stroke motorcycle gearboxes.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Suction Pumps are self-priming following the initial priming, and operate according to the bypass duct principle. We recommend pump models featuring bronze body elements for pumping water without anticorrosion additives. The dimensions are based on standard specification EN 12157. Impellers: open Fluids: coolants, cooling/cutting oils, fuel oil, water (with anticorrosive additive) Volumetric delivery: up to 52 l/min Delivery head: up to 16 m Please contact us for delivery quantity

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series V 600 - 1100 IS The HEINKEL Vertical De-oiling Centrifuge V 600 – 1100 IS is designed and built for the separation of cutting fluids and coolants from steel, cast and metal chips. Special properties for the customer’s benefit: Recovery of liquids and oil from chips produced by processing centres and from plastic pellets Simple and rugged design

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on aluminum profiles up to 3 mm of thickness. Copy fitting operates manually and the figures on the template are machined at 1:1 ratio The aluminum profiles up to 3 mm of wall thickness can be machined with a strong spindle motor The cutting fluid controlled with a joystick is sprayed to the milling spot Slots in varied lengths and widths can be opened without using the copy milling template The length of the water drain slot is adjustable on the template Copy milling motor is directly controlled via joystick Reference stops at 2 sides of the milling machine Standard equipped with inlet-outlet conveyor Ergonomic hand control unit STANDARD ACCESSORIES • Ø 5mmx L :80mm of router bit • Air gun • 2 x profile stops both left and right • Spray tool lubrication system • 2x horizontal clamps OPTIONAL ACCESSORIES • Additional router bits

Request for a quote

FIBALON GMBH

Germany

The use of filtration materials and systems in the field of industrial applications and the use of filter in the producing industries claim filter as well as filter systems on the highest degree. New fiber types with different surface modifications in a new combination, united in the innovative polymer fiber filter FIBALON®tool, offering unique and outstanding filtration results. By optimizing our developed dynamic fiber fixation DyFix® and a particle-dependent fiber geometry, we can now also offer our worldwide unique polymer fiber filter for the industrial use. For example in metal band saws to protect the pump or for the treatment of cooling lubricants and also for cutting fluids (e.g. in CNC machines) is FIBALON®tool with its highly durable special fiber combination an inexpensive alternative with improved filtration efficiency compared to conventional systems such as centrifuges or belt filter systems.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Top of range product for all difficult applications, all types of metal. Very efficient.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Micro-emulsion fluids, each designed for specific metals

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Generally used for both rough machining and finishing. For finishing operations when the shapes are complex and with very accurate dimensions.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Difficult machining and grinding.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Classical machining, brass bar turning. Works well on fine carbon steels.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Lubrication of cutting operations for multiple metals and machine tools.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Oil dedicated for grinding, profile grinding, sharpening and honing on ferrous metals

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

High performance biodegradable-based neat cutting lubricant

Request for a quoteResults for

Cutting fluid - Import exportNumber of results

28 ProductsCountries

Company type