- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- counting machine

Results for

Counting machine - Import export

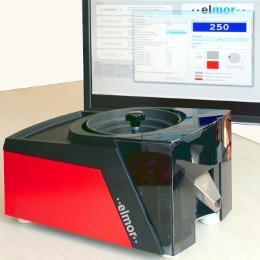

ELMOR

Switzerland

Counting machine elmor C1: accessories and variants Conveyor bowls The parts to be counted with the elmor C1 counting machine are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Dual Product Outlet The dual product outlet can increase the productivity in Preset Mode (= repetitive batch counting). Each time when a batch is counted, the outlet switches to the other side and the counter restarts automatically. The dual discharge chute is intended to be used for counting crop seeds or corn, which are filled directly into bags, but can also be used for other seeds with 1mm diameter or more. Automatic Seed Weight Sorter Each single seed of a lot is automatically placed on a scale. The Automatic Seed Weight Sorter measures the weight of each seed and compares it with one or several limits. According to the result of this comparison, the weighed seed is then transferred into two or more containers. So the parts can weighed and sorted either into good and bad parts or into several weight classes. Filling Carousel The C1 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Filling adapter Adapter for small containers, bottles, laboratory tubes etc. This adapter allows dustfine and costly parts to be filled directly into containers. The C1 seed counter can be started only when a container is present.The filling adapters are manufactured individually on request. Dust Cover If specific small parts are processed, a dust cover can be of advantage. This is for example the case with pharmaceutical components, implants or with parts that need to be processed in a protective atmosphere. In this case, nitrogen or other gases or may be introduced through the dust cover. Ionizer When transporting small parts in the vibrating conveyor bowl there is a risk that the parts can become electrostatically charged. The correct separation of the charged parts becomes difficult. With an ionizer, the charged parts can be neutralised, shortly before leaving the bowl, in the region of the sorting element. The ionizer used in elmor C1 seed counter is manufactured by a specialized company, which is represented worldwide. The head of the ionizer is attached inside of a dust cover. Receipt Printer for Seed Counter elmor C1 The result of each completed count is printed automatically. The printing is done in plain text and bar code. During sample preparation or inventory counts many customers have expressed a wish to be able to print the determined number immediately. This can be done with this new accessories for the C1 counter. Faulty manual recordings are obsolete. Technical data: Paper: standard thermopaper rolls, 80mm width. Internal cutter, label length 64mm Barcode: Code 128 (International Standard ISO/IEC 15417), other codes on request Power supply: 100 – 240V, 50/60Hz The C1 seed counter must be equipped with an elmor printer interface board Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of the counting machines elmor C1, C3 or CX Intermediate storage container of counted parts When a seed counter is combined with a packaging machine, it may be advantageous to add a container for synchronization therebetween. When the counting operation has finished and the packing machine is ready, a discharge flap is opened briefly, so that the content of the container is discharged into the packaging machine. Then the flap closes and the counting machine begins with a new operation. As a result, the waiting time that would be needed before a packaging machine is ready for the next lot can be greatly reduced, allowing a shorter cycle time. Depending on the task different volumes can be realized.

Request for a quote

CDA

France

The C-Pills, a semi-automatic machine designed for counting capsules and film-coated tablets, is a product of CDA tailored specifically for the pharmaceutical, food, and animal feed industries. It distinguishes itself through its robust construction, utilizing premium materials such as mirror-polished stainless steel, glass, and food-grade plastic (POM c). Operating with efficiency, the C-Pills relies on a vibrating hopper for a consistent supply of tablets and capsules to the rotary table. These pharmaceutical items are then guided with precision along the periphery of the Rotary Glass Table. As they move, they drop into a counting airlock, creating optimal spacing between each item through a laser curtain, facilitating accurate counting. With an impressive counting capacity of 1,000 capsules or tablets per minute (for size 0), the C-Pills ensures maximum productivity, meeting the high demands of the pharmaceutical industry.

Request for a quote

EVTEKS LTD

Turkey

A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 145- thread count Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 160- thread count Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

PERCALE A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 190- thread count Oeko-Tex® certified Machine wash. Made in Turkey POPLIN A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 160- thread count Oeko-Tex® certified Machine wash. Made in Turkey RANFORCE A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 145- thread count Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS STRIPE Made of 100%Turkish cotton. 0,5 MM 210 -thread count 10 MM 255 -thread count 20 MM 305-thread count 400-thread count Oeko-Tex® certified Machine wash. Made in Turkey DETAILS Made of 100%Turkish cotton. 224 -thread count checked satin DETAILS Made of 65%Turkish cotton 35% polyester 225 -thread count 4 stripes satin 0,5 mm stripes satin

Request for a quote

EVTEKS LTD

Turkey

A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 210- thread count 255 -thread count 305-thread count 400-thread count Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 190- thread count 210 -thread count Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

An embroidered trim in a tonal palette is an elegant finishing touch to these sheets. They pair well with solid or printed bedding A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. Made of 100% turkish cotton. 210- thread count 255 -thread count 305-thread count 400-thread count Oeko-Tex® certified Machine wash. Made in Turkey Pairs well with our towel collection DETAILS Made of 100%Turkish cotton. 500 g/sqm terry towels Oeko-Tex® certified Machine wash. Made in Turkey

Request for a quote

EVTEKS LTD

Turkey

PLAIN STAIN BED SHEETS A cotton weave is a tightly woven weave, which gives the fabric a soft finish while providing durability and ultra breathability. DETAILS Made of 100%Turkish cotton. 210- thread count 255 -thread count 305-thread count 400-thread count Oeko-Tex® certified Machine wash. Made in Turkey STRIPE Made of 100%Turkish cotton. 0,5 MM 10 MM 20 MM CHECK DESIGN SATIN Made of 100%Turkish cotton. 224 -thread count checked satin 4 STRIPES SATIN Made of 65%Turkish cotton 35% polyester 225 -thread count 4 stripes satin 0,5 mm stripes satin

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The machine fully automatically counts the small spare parts and packs them into a bag. Spare parts like screw nut bolt hardware or fastener accessories parts. Filling into a zipper bag or vffs pillow bag or tubular bag.It is faster than a hopper counting machine and high accuracy than a normal weighing machine. 1. Accurate: overlap can also be accurately counted,Statistical error is less than 1‰, only positive error. Relative to the maximum error of 10 - 20 grains of weighing and packaging equipment on the market, the product can save more than 1% of material cost waste.2. Fast: 12,000 grains/minute (φ1.2mm) .For 10 mm square connector material, speed 6-7 packs per minute, 1000pcs. 3. Strong compatibility: N materials can be counted in one machine.4. One-click emptying of remaining materials and quick replacement. 5. Interconnected with ERP system. 6. Exceeding standard packages can automatically enter the return system.7. Intelligent detection and alarm function.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1 Accuracy:99.9% according to the quantity with fiber counting which is a much big range of direct, fast, and stable reaction speed.End weighing director is optional for higher accuracy by rejecting the out tolerance dose. 2 Capacity: About 100~300 pcs /min per plate according to the exact product. 3 Durable: Lower malfunction rate and Lifetime of About 10 years. 4 Versatility: The same one torsional vibrator is able used for a certain range of products in different sizes and shapes. Ergonomic condition: ergonomic condition operation area for the parts manually feeding which is unworkable with the machine. Feeding: Staff is convenient for feeding enough parts into the torsional vibrator which the height is about 800~900mm above the grand.A fully automatic elevator or hopper is optional. Quickly format change: remaining parts will be cleared in 5 min by pressing one button. Lower Noise and surface wear with the specific glue on the surface of the torsional vibrator.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts like screws, bolts, nuts, washers, springs, and plugs. High precision and fast, save the labor cost you. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. The lot number or other printing information is an optional device. Feature 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s fully automatic counting and packing machine for Furniture kit and hardware spare parts.You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in bag and open the machine. Feature: 1. According to screw/special parts sample tailored to the vibration plates with precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, whole machine is more secure, stable, reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduce wastage. 4. It completes the whole procedure of metering, filling,bagging,date printing, charging(exhausting),counting automatically. 5. Unique design of the packing seal technology, make the sealing nice and strong. 6. Equipped with chain conveyor trailer,it can be feed by manual if the vibration plates is un-workable.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. Feature: 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduced wastage. 4. It completes the whole procedure of metering, filling, bagging, date printing, charging(exhausting), and counting automatically.

ELMOR

Switzerland

The packaging machine elmor 800 is a small, compact and versatile packaging machine for premade bags like seed sachets. The machine can be combined with all elmor seed counters, but also with counting devices from other manufacturers or with other dosing devices such as dosing scales or volume-dosing machines. The seed counting and packaging machine elmor 800 can fill and close sealable flat bags or pregummed bags. In addition to the filling and closing, the bags can also be marked with an inkjet printer. Changing of the bags requires only a few seconds. A replaceable bag stack allows changing to other formats without time-consuming adjustments. Just change the stack and continue. Therefore, the packaging machine elmor 800 is especially suited for the packaging of seed specialties or organic seeds where many different varieties, but mostly small batch sizes have to be packed. The packaging machine elmor 800 is designed as a table top model.

Request for a quote

ELMOR

Switzerland

Filling machine for XY arrays Biaxial positioning device for automatic filling of microtitre plates, arrays of vials, tubes, or containers in one or two dimensional arrangements with the elmor counting machines. The modular designed elmor 900 filling machine may be configured individually for different types of containers or different plate shapes and sizes, e.g. for microtitre plates with 6, 12, 24, 48 or 96 wells. The machines may be modified to cater for a wide variety of applications and customer requirements. Picture: Example of a XY-filler for 6 microtitre plates with a temperature-controlled base plate.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELMOR

Switzerland

Seed counter, counter for small parts elmor C1 The elmor C1 is a universal counting machine for any small and irregularly shaped parts, such as: Finest plant seeds Vegetable seeds Cereals, Maize, Rice, Canola Insects, Pupae, Eggs Pharmaceuticals, pills, casules Gems, diamonds and precious stones Bulk semiconductor chips Small mechanical parts Implants All these products have in common is that they are either irregularly shaped, lightweigt or very small. Therefore these parts are difficult to handle manually. Dosing these parts with scales is often flawed or impossible. The seed counter C1 is specialized for exactly counting of such parts in small to medium quantities. Important applications of the C1 seed counter are the repetitive, precise counting of a preselected number of parts or the conventional determination of the 1000 grain weight according to ISO 520:2010. Parts with diameters from 0.2mm to about 18mm can all be processed with the same adjustable conveyor bowl. For fast counting of large amounts the 650 multi-channel counting machine can be used. The seed counter C1 is characterized by a robust construction, a fool-proof operation and a large, bright display that is easy to read even in daylight. The count signal is processed by a microprocessor which allows also the detection of parts with particularly difficult shapes. The parts counter C1 is equipped with terminals for remote control so that it can be combined, for example with packaging and filling machines. The C1 seed counter is the successor of our model 600, which was produced from 1980 for about 25 years. The new seed counter elmor C1 combines modern electronics with the proven key components that were already responsible in the previous model for long durability and unmatched accuracy. The C1 can be described with attributes such as longevity, durability, robustness and reliability – this for many years. Technical data Counter for small parts from 0.2 to 18 mm in diameter (*) Cylindrical parts can have a length of up to 20 mm (*) Only one adjustable conveyor bowl is used for the whole size range Conveyor bowl: anodised Aluminium, sorting element FS-0. Other bowls and sorting elements available on request Display and preset range of the counter: 0 to 99’999 Modes of operation: Preset counter, Totaliser The conveyor speed is reduced shortly before reaching the desired quantity to achieve a high dosing accuracy External connections allow the combination of the seed counter C1 with other devices, e.g. packaging machines. Typical performance data for spherical parts of 2mm diameter: Counting speed: about 50’000 parts per hour Counting error: 1/10’000 for clean, easy to separate parts Modes of operation: Totaliser Preset counter (*) other sizes on request The C1 counting machine is the central part of a system that can be adapted for many different applications. Some variants are standardized available, such as: Conveyor bowls for specific tasks Counter with dual product outlet Automatic seed weight sorter Filling carousel for bags and/or vials Filling adapter for containers Dust cover Ionizer Receipt printer Feeder / hopper with a few litres storage volume If your application can not be covered with these accessories, please contact us so that we can propose you a customized solution. elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

ELMOR

Switzerland

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quote

ELMOR

Switzerland

The elmor CX counter module is mostly used as dosing unit on packaging machines. The open constructed counting head has a narrow width. Thus, multihead dosing systems can be realized easily also in tight spaces. The CX counter module consists of two parts: the counting head with conveying unit and sensor and the control unit. The control unit of the CX counting module is completely remote controlled via a PLC. The technical data of the CX counter module are quite similar to the data of our C1 seed counter. Example: Dosing module with 4 counter heads Multihead seed counter using the elmor CX With courtesy of: Tempel Verpakkingstechniek (NL) For more information please contact: info@vandertempel.nl Technical data Countable parts: 0.2 to 18 mm in diameter Cylindrical parts up to 20 mm length All sizes are counted with the same adjustable conveyor bowl; for parts with extreme shapes or sizes the sorting element can be customized The conveying speed can slow down automatically shortly before reaching the desired amount to achieve a high dosing accuracy. Spherical parts of 2 mm diameter have the following performance values: Counting speed around 50,000 pieces per hour Counting error: 1 per thousand or less The counting range and the count modes are determined by the PLC Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowl of the counting machine elmor CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The OPTIMA PAKSIS D7 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick changeovers. The packaging machine OPTIMA PAKSIS D7 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS D7 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The Packaging Machine OPTIMA PAKSIS A6 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick change overs. The OPTIMA PAKSIS A6 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS A6 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

RNA AUTOMATION LTD

United Kingdom

RNA offer as part of a total package the design and manufacture of bespoke handling systems which include vision systems and pick & place handling units often combined with vibratory bowl feeders. From a vision inspection system for checking out of tolerance components, counting systems for bagging machines, utilising the latest pneumatic and electric linear slide systems RNA can supply a system to move manipulate and handle your components.

Request for a quote

TEKNO MILLING MACHINES CO. LTD

Turkey

As Tekno Milling Machines Co. Ltd that founded in Mersin Turkey, we offer turnkey completed seed,pulses,cereals,nuts,spices processing screening crushing and cleaning plants also following agricultural machines and spare parts. Seed Cleaning and Processing Machines : Pre-Cleaning Machines,Classical Screening Machines,Excel Cleaners,Destoners,Gravity Separators,Indent Cylinders,Brushing Machine,Liquid Treatment Machines,Color Sorting Machines,Bagging Machines,Dehullers,Millers Packaging machines: Vertical packaging machines,Rotary Type Packaging Machines,Filling Machines,Seed Counting Machines,Bailing Machine Post Packaging Systems: Carton Packing Machines, Streching Machines ,Shrinking Machines,Vacuum Machines,Metal Dedectors,Printers,Carton Coding Machines,Sticking Machines Silo Systems : Elevators,Conveyor Belts,Screw Conveyors,Silo Systems Please visit our website for all.

Request for a quoteResults for

Counting machine - Import exportNumber of results

25 ProductsCompany type