- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- counter-frames

Results for

Counter-frames - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Discharging, feeding, conveying In many industrial production processes, sharp or hot waste bulk has to be handled (e.g. metal shavings, foundry sand or slugs). Often, it has to be transported over long distances underfloor before it will be disposed or re-processed. The use of conveyor belts often leads to difficulties due to high wear and overflowing of the floor trenches. The result: high maintenance costs, frequent cleaning of the ditches, thus interrupting production. The optimal solution for these tasks are our AViTEQ conveying guided arm troughs. Advantages & Benefits low height transport of hoarse products careful product transport longer gutter trough dust-proof design Construction The gutter trough is on trailing arms connected to a counter-vibration frame, this in turn is mounted on springs, this combination ensures that the dynamic forces are isolated up to 99 %. This allows frames and foundation are kept very small. Selection The dimensioning of the reversing convey

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

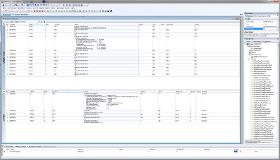

The µCAN.explorer is a universal monitor used to supervise data streams within a CAN network. The single messages are assigned individual names (symbols) in order to ensure a clear and simple classification The integrated data logger facilitates the data stream being acquired and saved onto the bus.Display of all received messages with indication of ID, length and data bytes Display of all received remote-frames as well as indication of their number and reception interval Storing and loading of compiled sender lists for emulating different CAN nodes Errors of the CAN bus and the controller are indicated, including error-frame-counter Supports various file formats, incl. Float according to IEEE754 and enumerations (Enums), byte order adjustable to Intel and Motorola format

Request for a quote

FRIGO SYSTEM

Turkey

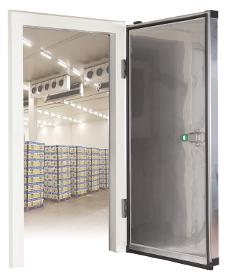

Hinged Cold Room door designed and constructed to suit the demands of cold storage and the food industry are manufactured with polyurethane foam technology of a high heat insulating level, with a thickness of 60-120 mm depending on the door types, from stainless steel or polyester coated plates. In each case, the doors come with PVC frame structure, and in cold storage temperature range, the doors are fitted with a threshold sunk below the floor level and with built-in heating. Smaller doors and doors used in the medium temperature range are fitted with a frame closing the panel opening, which is extremely simple to put in and is also suitable for covering the cold room panel edge, so there is no need for a counter-frame or for subsequent panel closing when putting in the door.

Request for a quote

ELMOR

Switzerland

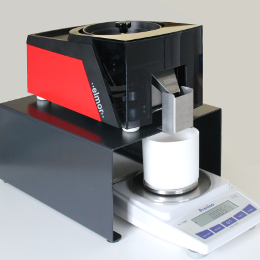

With seed tests the 1000 kernel weight is an important quality criterion, which must be determined with high accuracy. Counting and dosage of mechanical and electronic small articles as SMD’s are made increasingly also over the determination of the 1000 grain weight. By means of an additional software module, an electronic balance and a special frame, our precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Technical data Scales are available with a resolution of 1 mg, 10 mg or 100 mg. The data of the elmor C3 seed counter and the scale are sent to the control computer via two RS232 ports or – on request – with two USB cables.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAMA AERNOVA SRL

Italy

Cutting Table with structure for maximum thicknesses of 30mm sheet metal 260 A. The LT downdraft cutting table, integrated with a laser, plasma, or oxyfuel cutting machines, enables the sustain and processing of the sheet metal plates, with the required extraction of fumes & dust, and a slug collector system Benefits The suction table is divided into sections, activated by the cutting machine, to concentrate fume and dust extraction only where suction is necessary, reducing the air flow required and optimising energy consumption.The suction table can support sheet metal plates with a maximum thickness of 30 mm, and torches with a maximum power of 260 A. The slag containers could be easily removed from the top (after the lifting of the counter frames) without interfering with the outer structure of the machine, to simplify the slag empting procedures. The cutting bars of the counter frames can be individually replaced, in an easy and fast way. The LT downdraft cutting table is...

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Non-closable venting panel that with a pressing break opens itself letting the area completely free. The opening takes place thanks to the carvings breakage and relative “extraction” of the panel from its gasket. The plastic hinge guarantees that the panel remains opened without any projection of panel or counter-frame parts. This type of safety device is intended for protection from possible explosions, caused by a sudden pressure increase of equipments containing air/dust mixtures or gas/air potentially explosive mixtures such as silos, separator filters, bucket elevators, sieves, mixers, tanks, canals and pipelines, dust collectors, dryers, etc. All panels are breaking and safety devices and have been certified in accordance with UNI EN 14797: 2007. Opening efficiency: Ratio between the relief and the total area. Relief area: Area of the supposed venting device which is free from inertia. It shows the same effects of pressure reduction of the real device. Kst...

Request for a quoteResults for

Counter-frames - Import exportNumber of results

9 ProductsCountries

Company type