- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper strips

Results for

Copper strips - Import export

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. They are windly used in automotive industry; radiators, cable industry, electronic and electrical industries; decorative components and Building industry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 5mm to 160mm, Thickness of 0,10mm to 10mm. Copper strips are produced, hot and cold rolling , by extruded OF busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599 also EN 13601

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. they offer great resistance to corrosion.They are widly used in automotive industry; radiators, cable industry, electronic and electrical inustries; decorative components and Building inustry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 10mm to 160mm, Thickness of 0,20mm to 6mm. Copper strips are produced, hot and cold rolling , by extruded busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599

Request for a quote

JINTIAN COPPER

Germany

Main products: High-precision tin phosphor bronze strips, copper strips, brass strips and white zinc copper strips Product characteristics: Good yield strength and fatigue strength, good elastic properties, excellent processing and bending properties, good ductility, durability and corrosion resistance Applications: Electrical and electronic devices, communication technology, electrical network, hardware, construction industry, home appliances Production capacity: 104,000 tons Honorary titles: Zhejiang Famous Brand Product, China's Top 5 Copper Strip Company

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product Name: Copper Tin Nickel Alloy Width:10-630mm Material:Bronze Grade: Oxygen Free Copper Cu (Min): 75% Model Number:Copper Alloy Place of Origin: China Size: Customised Standard: JIS ASTM DIN EN ISO Certificate: SGS / ROHS / ISO9001:2008 Package: standard export packing Price Term: CIF CFR FOB Ex-Work etc. Usage: Electric Components Lead time:20 Days

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

width 100mm thick 0.02mm

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

99.9% Pure copper tape / strip

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Glass pipe bends For conveying abrasive media or for high flow rates, we can supply you with glass pipe bends made from 3.3 borosilicate glass with a copper grounding strip. These have a service life at least 10 times longer than that of stainless steel pipe bends. made of 3.3 borosilicate glass leg extension 200 mm copper grounding strip attached at the outer radius

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For stripping and cutting copper and aluminium cable • Improved cutting geometry for simple cutting and higher operating times • Ratchet-shaped clamping of the cable ensures crimp-free cutting • Precision cutting edge for a smooth and clean cut without any burrs • Not suitable for steel wire, aluminium alloys and hard-drawn copper conductors • Re-adjustable screw-joint • Handles with ergonomically shaped SoftGripp multi-component sleeves • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Ergonomic handle position and shape for optimum power transmission • Professional design for easy handling under permanent load • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For stripping and cutting copper and aluminium cable • Improved cutting geometry for simple cutting and higher operating times • Ratchet-shaped clamping of the cable ensures crimp-free cutting • Precision cutting edge for a smooth and clean cut without any burrs • Not suitable for steel wire, aluminium alloys and hard-drawn copper conductors • Re-adjustable screw-joint • Handles with ergonomically shaped SoftGripp multi-component sleeves • SoftGripp handles with SystemSocket for holding optionally available accessories, e.g. the easily attached SystemClip for fall protection • Professional design for easy handling under permanent load • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For stripping and cutting copper and aluminium cable • Improved cutting geometry for simple cutting and higher operating times • Ratchet-shaped clamping of the cable ensures crimp-free cutting • Precision cutting edge for a smooth and clean cut without any burrs • Not suitable for steel wire, aluminium alloys and hard-drawn copper conductors • Re-adjustable screw-joint • Handles coated with plastic • Professional design for easy handling under permanent load • Made of special tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For stripping and cutting copper and aluminium cable • Improved cutting geometry for simple cutting and higher operating times • Ratchet-shaped clamping of the cable ensures crimp-free cutting • Precision cutting edge for a smooth and clean cut without any burrs • Not suitable for steel wire, aluminium alloys and hard-drawn copper conductors • Re-adjustable screw-joint • Handles coated with plastic • Professional design for easy handling under permanent load • Made of special tool steel, forged, oil-hardened

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Copper 102 is an oxygen-free copper with extremely high electrical conductivity and good formability. These characteristics make it particularly useful for electrical connectors. Copper 102 can be deep-drawn from the annealed temper.It is corrosion resistant in normal atmosphere and water. A thin adherent oxide film forms at elevated temperatures which prevents particle contamination and enhances glass to metal seals. The Copper 102 can be readily soldered and brazed. The absence of oxygen makes welds free of inclusions. Available Sizes: Copper 102 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B 152 and UNS C10200. It is also available in thickness less than 0.0005” (0.0127 mm) in widths up to 4.000” (101.6 mm) maximum.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Copper alloys exhibit very high electrical and thermal conductivities, offering twice the conductivity of aluminum and thirty times the conductivity of stainless steel. Other advantageous characteristics include outstanding strength (notably copper beryllium alloys) and corrosion resistance as well as antimicrobial properties. Copper is most commonly used in electrical and electronic applications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our specialized Pfinodal® C72900 material is a Spinodal copper based alloy with nickel and tin additions. It competes with Beryllium Copper alloy C17200 for electrical connectors and bearing materials where high strength and excellent formability without dimensional instability are required.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Constantan® is a copper-nickel alloy that contains specific minor amounts of additional elements to achieve precise values for the temperature coefficient of resistivity. Careful control of melting and conversion practices results in a very low level of pinholes at ultra-thin thicknesses. The alloy is used extensively for foil resistors and strain gauges. The TCR can be adjusted from the furnished cold rolled values by using a low temperature heat treatment to achieve compensation for all types of spring elements. The foil is normally supplied with 90% cold reduction and a smooth bright surface. The foil is reasonably flat at 4” wide and nearly free of pinholes. The cold rolled foil can be produced with a TCR between +10 to –35 PPM/°C. The heat treatment will shift the foil TCR to the desired value. A typical heat-treat curve for Constantan® shows decreasing resistivity but increasing TCR with increased heat-treating temperature.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Phosphor Bronze A is a Copper base spring material with a good combination of strength, formability, and corrosion resistance. The material is suitable for use in certain contact springs and diaphragms. The alloy has good formability up to moderate strength. It can be soldered, silver brazed, and resistance welded. Available Sizes: Phosphor Bronze A is available from Hamilton Precision Metals as strip products in thicknesses from 0.001” to 0.020” (0.0254 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B 103 and UNS C51000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Beryllium Copper 25 is a Copper base alloy with the capability of being strengthened by precipitation heat treatment. The alloy furnishes the best combination of electrical conductivity, corrosion resistance and mechanical strength necessary for numerous electronic and electromechanical devices. The alloy is quite satisfactory for fabrication with good formability and joining characteristics. Forming is readily accomplished from the annealed temper. Severe bending will be less successful from hard or heat treated tempers and requires large fold radius ratios. Beryllium Copper 25 is able to be soldered, brazed, and welded by most standard techniques. The brazing temperature must be kept under 1450º F and cycle time minimized to avoid loss of heat treated strength. Heat treating should be performed subsequent to welding to obtain uniform high strength. The alloy is not susceptible to an increase in magnetic attraction from plastic deformation during service

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Shunt Manganin is a Copper-Manganese resistance alloy used for shunts in various high current applications. The alloy has a low temperature coefficient of resistivity with peak resistance at about 50°C. The thermal EMF vs. Copper is very low. The alloy can be easily formed from the annealed temper.The maximum recommended operating temperature in air is 200°F. Available Sizes: Shunt Manganin is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005 to 0.053” (0.0127 mm to 1.346 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000100” (0.00254 mm) in widths of 4.0” (101.6 mm) maximum.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Here at Hamilton Precision Metals, we’re passionate about cold rolling metal strip in a diverse range of specialty alloys to meet your exacting specifications. Our extensive precision strip product range include stainless steel strip, nickel strip, titanium strip, copper based strip, cobalt based strip and many more alloys. We have the expertise to roll light gauge strip from 1.5 mm (.060”) down to 0.127 mm (0.005”). Broadest Range of Alloys We offer an extensive portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®,

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Spinodal strip materials in Copper-Nickel-Tin alloys offer high ductility for forming into shaped charge liner material for the perforation of oil and gas well liners. Shaped Charge Liner Material Advantages The Spinodal material is produced through our wrought powder compaction process which imparts properties allowing the material to virtually ‘disappear’ upon activating the charge. The material is well suited to “big hole” applications for perforating charges and leaves little residue (commonly referred to as ‘carrots’ or ‘slugs’). Pfinodal® (C72900) and AM-388™ (UNS C72650) We produce two spinodal alloys for these shaped charge applications - Pfinodal® (C72900) copper alloy and AM-388™ (UNS C72650). They benefit from age hardening techniques that further increase their strength and hardness required for deep hole penetration applications. These spinodal materials deliver superior mechanical and physical properties in comparison

Request for a quote

JINTIAN COPPER

Germany

Main products: HPb59-1、HPb60-2、H62 and other grades of leaded brass plates Product characteristics: Strong corrosion resistance, good elasticity, good formability and weldability, good strength Applications: Copper key blanks, copper engraving, electronic connectors, handicrafts Production capacity: 25,000 tons Honorary titles: Zhejiang Famous Brand Product, China's Top 5 Copper Strip Company

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our highly specialized Spinodal materials are custom-engineered for electronic connectors and deliver major advantages in comparison to traditional materials such as Beryllium Copper (BeCu). We offer precision strip and wire products in alloy Pfinodal® (UNS C72900), a copper nickel tin Spinodal alloy, for the manufacturing of high performance electronic connectors in the electronics industry. Safe Alternative to Beryllium Copper (BeCu) Beryllium Copper (BeCu) materials are the historical choice for electronic connectors. Our high performance Pfinodal® (UNS C72900) delivers similar mechanical properties to Beryllium Copper but without the harmful exposure risks.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability. That’s why leading defense programs use our high-performance materials. Leadership in Defense Metals We have more than 50 years of experience developing precision strip and thermal management products for critical defense applications worldwide. Our defense portfolio includes: Thermal management materials for semiconductor heatsinks Nickel strip for battery connectors High Performance Defense Alloys Molybdenum Copper (AMC) and Tungsten Copper (AWC) High purity nickel strip Trusted for Critical Defense Applications Due to their excellent thermal conductivity and controlled thermal expansion, our Molybdenum-Copper and Tungsten-Copper composites are the preferred materials for Gallium Arsenide (GaAs) and Gallium Nitride (GaN) semiconductors for the defense industry. Our heat spreader materials are trusted in sensitive applications such

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

Description - borosilicate glass 3.3 - ends fire-polished - with copper strip bends (glass).pdf

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

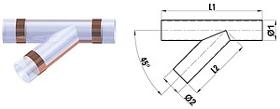

branch pieces 45° - borosilicate glass 3.3 - ends fire-polished - with copper strip Ø1 (mm) Ø2 (mm) L1 (mm) L2 (mm) FS.45.044.32.044.32.GL 44 44 250 160 FS.45.054.35.054.35.GL 54 54 250 160 FS.45.065.42.065.42.GL 65 65 250 160 L-pieces - borosilicate glass 3.3 - ends fire-polished - with copper strip Ø (mm) R RB.044.32.0090.90.100.100.GL 44 90 RB.054.35.0090.90.100.100.GL 54 90 RB.065.42.0090.90.100.100.GL 65 90 T-pieces (one side closed) - borosilicate glass 3.3 - ends fire-polished - with copper strip Ø1 (mm) Ø2 (mm) L1 (mm) L2 (mm) FS.TC.044.32.044.32.GL 44 44 210 155 FS.TC.048.32.048.32.GL 48 48 210 155 FS.TC.054.35.054.35.GL 54 54 210 155 FS.TC.065.42.065.42.GL 65 65 210 155

Request for a quoteBY CARPEL S.R.L.

Italy

Material PVC PVC Weight 1.21 kg/m Lengh’s bars from 1 to 4 m Colour Grey or green Item P1 Material of current strip Copper 70A 100A 140A Section conductor 15.5x1 15.5x1.5 15.5x1.8 Weight conductor 0.15 Kg/m 0.20 Kg/m 0.25 Kg/m

Request for a quoteResults for

Copper strips - Import exportNumber of results

30 ProductsCompany type

Category