- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cooling system services

Results for

Cooling system services - Import export

KURARAY (EVAL EUROPE N.V.)

Belgium

Pre-insulated pipes are incresingly popular for centralised and energy efficient district heating and cooling systems. Â A central service pipe is surrounded by PUR foam insulation and a durable HDPE outer cladding. Adding an EVALâ„¢ layer to the pipe structure helps extend system service life, by maintaining insulation efficiency and structural integrity. Â EVALâ„¢ helps make sure pre-insulated pipe systems performs not only longer, but more efficiently as well.

HATEBUR UMFORMMASCHINEN AG

Switzerland

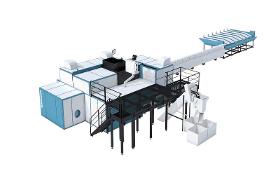

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

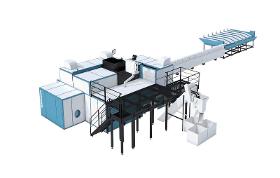

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

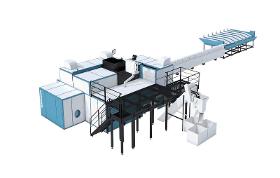

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HAMON

Belgium

An indirect dry cooling system is characterized by the use of a condenser and air-cooled heat exchangers.The cooling system consists of the following main components :condenser (surface or spray type),cooling water circulating pumps and recovery turbines, if applicable,heat exchanger deltas including louvers,natural draft cooling tower,piping and valves,water storage tanks and transfer pumps,electrical equipment,instrumentation and control,accessories such as cleaning system, nitrogen blanketing system,The warm water from the condenser is delivered to the natural draft cooling tower by the cooling water circulating pumps and an underground piping network. After the cooling in the heat exchangers, the cold water returns to the condenser.

Request for a quote

HAMON

Belgium

Forced draft cooling towers are specially designed to handle zinc sulphate solutions or highly corrosive liquids. They are equipped with distribution in highly resistant material.EFFECTIVE DESIGN COMBINING performance easy access for easy maintenance - sprayers are accessible without scaffolding and removable minimization of drift losses: 0,001% and lower. SUITABLE FOR HIGHLY CORROSIVE LIQUID WITH 200gl/ sulphuric acid, Presence of fluorine, Crystallization of gypsum

Request for a quote

HAMON

Belgium

The cooling tower with plume abatement (also called hybrid or wet/dry) is an evaporative cooling tower combined with a dry heat exchanger, used to abate the cooling tower plume. This is the best available solution where local constraints are such that the presence of plume is not accepted in normal conditions (along motorways, airports, close to residential areas).Hamon has an unrivaled reference list in this field.Plume abatement can be offered with mechanical draft cooling tower (cells) as well as with fan assisted natural draft (circular hybrid).ADVANTAGES: no plume visibility. outstanding performance of an evaporative cooling tower. cost attractiveness. all types of heat exchange media. for cell CT :same flexibility as an induced draft cooling tower. all types of structure (wood – frp – concrete – steel)

Request for a quote

HAMON

Belgium

The induced draft cooling tower generally offers the most effective and economical solution to most of cooling needs. Hamon has supplied numerous IDCT worldwide for all power and industry applications and all environmental conditions. The IDCT offers the following advantages:flexibility. cost effectiveness. air flow almost constant regardless ambient air temperature. adapted to any water flow .flexible operation by shutting some cells. adapted to high thermal performance .all types of structure – wood, FRP, concrete, steel. all types of heat exchange surfaces from splash grids to high performance film

Request for a quote

HAMON

Belgium

Plume-abated fan assisted natural draft or circular hybrid cooling tower is the best technical solution for large heat loads and stringent plume abatement requirements.Seawater application. If overall height is limited. To keep countryside free from visible plume formations and shadow .For locations close to residential areas .To facilitate permission processes. ADVANTAGES VS CELL TYPE HYBRID COOLING TOWER: Compact arrangement/space saving. No recirculation and interference effects. No wash down (grounding) effects of plume. Use of natural draft. No corrosion due to humidity and salinity in the neighborhood. Visually an interesting architectural structure.

Request for a quote

HAMON

Belgium

The fan assisted natural draft cooling tower (FAND) combines the advantages of the natural draft cooling tower and the mechanical draft cooling tower.It becomes the best available technology when :Locations with limited plot plan. Overall height is limited. Important heat load . ADVANTAGES VS. CELLS: Compact arrangement. Power saving due to natural draft. No recirculation. Always a good alignment considering wind directions. Cooling by natural draft in case of electricity shortage.ADVANTAGES VS. NATURAL DRAFT CT: Reduced height. Better cooling characteristics during the summer season. Higher flexibility

Request for a quote

HAMON

Belgium

The natural draft cooling tower is the right choice for large power plants.It offers the following advantages :power saving (no power consumption to induce air flow- no fan).environmentally friendly.no mechanical noise (no fan).safety of operation.no recirculation as the plume is rejected at high level.limited plot area.limited maintenance.high longevity (generally more than plant life expectancy).Payback period between 8 and 16 years depending on several factors.Hamon offers both basin or water collecting devices. This last solution, developed by Hamon, is recommended for large cooling towers.It offers the following advantages :less pressure drop in the air inlet.reduction of pumping power.decrease of acoustic pressure in air inlet

Request for a quote

REFRA, UAB

Lithuania

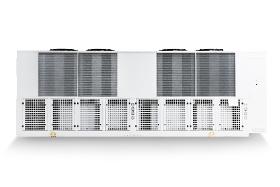

Free cooling system consists of a heat exchanger that cools down glycol mixture by using low temperature ambient air. When outdoor temperatures are lower relative to indoor temperatures, the system utilizes the cool outdoor air as a free cooling source. These energy-efficient units are perfect for industrial refrigeration or air conditioning processes, as they help to reduce mechanical energy consumption up to 80% and reduce maintenance costs as well as environmental impact. Comprehensive modular frame construction is assembled with high-quality EC fan motor technology, finned tube heat exchangers, 3-way valve and circulation pump. The galvanized steel and powder coated frame with a reliable insulation material ensures proper unit protection.

Request for a quote

REFRA, UAB

Lithuania

Free cooling system consists of a heat exchanger that cools down glycol mixture by using low temperature ambient air. When outdoor temperatures are lower relative to indoor temperatures, the system utilizes the cool outdoor air as a free cooling source. These energy-efficient units are perfect for industrial refrigeration or air conditioning processes, as they help to reduce mechanical energy consumption up to 80% and reduce maintenance costs as well as environmental impact. Open frame construction can be assembled with high-quality EC fan motor technology, finned tube heat exchanger, 3-way valve and circulation pump. The galvanized steel and powder coated frame ensures proper protection of the internal unit construction.

Request for a quote

ROSEN COOLING TECHONOLGY

Turkey

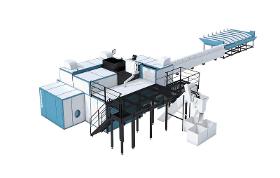

Full Automatic Ice Storage System ( Ice Rake Technology ). ROSEN Full Automatic Ice Rake Storages and Delivery System is the perfect combination with a Flake Ice Plants with this, certain amounts of ice can be stored over a period and discharged on demand and for covering demand peaks. An entire daily capacity of the ice plant can be discharged during the production in a short period. Even excess production capacity will fill the ice storage and is not lost.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

The CTT-EC-HV406L energy storage system has a wide range of applications, including but not limited to renewable energy integration, grid assistance services, commercial and industrial applications, and emergency response scenarios. In solar or wind farms, it can balance energy production with demand and improve the utilization of renewable energy. In the power grid, it provides auxiliary services such as frequency modulation and peak regulation, which helps to enhance the stability and reliability of the power grid. In business centers or industrial parks, it can be used as a backup power source or for peak cutting and valley filling to help reduce energy costs. In emergency situations, such as natural disasters, it also provides critical power support to ensure the normal operation of rescue and communication equipment.

Request for a quoteResults for

Cooling system services - Import exportNumber of results

19 ProductsCompany type