- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cooling belt

Results for

Cooling belt - Import export

FORBO SIEGLING GMBH

Germany

Different mesh sizes with open areas of 60% max. make Forbo mesh belts ideal processing belts for cleaning, drying, filtering and cooling. The belts can be supplied in different versions, for example with reinforced belt edges, with fibre-glass or Kevlar-fabric, with tracking- and lateral-profiles.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

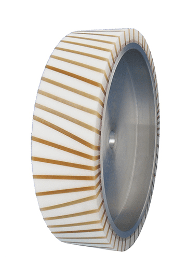

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the contact wheel FAPI-PUS DENSE, the aluminium hub is coated with dense adjoining polyurethane foam lamellae. The height of the coating resp. the length of the polyurethane foam lamellae can be varied depending on the application (standard: 20 and 35 mm). The polyurethane foam lamellae provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled parts. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-PUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat generated during belt grinding. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide lamellae of foamed up Vulkollan® are attached at alternating angles with plastic foam lamellae attached in the spaces between them to the aluminium hub of the FAPI-KS/V SPECIAL. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The longer the lamellae are, the less rigid the material becomes, which in turn reduces the aggressiveness of the contact wheel. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. Benefits of contact wheels with this design: Maximum removal rate Plastic lamellae provide optimum cooling of the abrasive belt Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIRE BELT COMPANY LTD

United Kingdom

Wire Belt’s TC-327™ tortilla cooling conveyor belt is designed with 74% open surface area, which allows for maximum airflow on tortilla cooling lines. TC-327™ is made of stainless steel, which helps to prevent product sticking from moisture. TC-327™ uses our XT® belt pattern that provides optimal product support and minimises product loss. TC-327™ comes standard with our patented C-CureEdge® edge loops which helps prevent belts catching and improves safety. TC-327™ also comes standard with our EZ-Splice® belt joining strand which gives you the strongest joining method available for increased belt life.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Capable of generating wide-angle flat spray even at low liquid pressure. Clog-resistant Spray direction is 75° to the nozzle axis. Applications Cleaning: Conveyor belts, film, eliminator plates, plate glass, planks Foam breaking: Wastewater treatment, paper manufacturers Cooling: Conveyor belts, roofs, tanks Water screen: Fire protection, heat protection, deodorization

Request for a quote

ALFA BREAD

Turkey

Full set of Arabic pita bakery equipment that you need to start producing perfect Arabic pita bread Fully automatic Lebanese bread production line Arabic pita bread machines include dough kneading machine dough proofer x 2 dough sheeter Oven Cooling conveyor belt Arabic pita bakery production capacities can range from 2000 to 12.500 pcs /h Lebanese bread line warranty 100% Automatic Arabic pita bread production line is designed to fit big and small production spaces Free training on how to make Arabic bread and free installation Full after-sales service for more details about Arabic pita bakery equipment www.alfabread.net 00905527066558

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Finishing on a sanfor line provides the fabric with a more stable structure, a silklike shine, a smoother touch and minimum residual shrinkage. The rubberbelt compacting line is made for the sanforisation and compacting of woven fabric and some kinds of knitted fabric, in combination with a felt belt calender the fabric gets on these lines additionally a special touch. The benefits are among others optimum residual shrinkage due to the hightech drive concept, stabilisation of the fabric structure, silklike shine, soft fabric touch, absolutely constant shrinkage due to a new automatic shrinkage control system available as option, production speeds up to 100 m/min are possible, extended service life of the rubber belt due to the larger diameter of the compacting rollers and an optimised rubber belt cooling system, integrated menudriven rubber belt grinding process, minimisation of vibrations, all bearings arranged outside of the wet area and therefore no corrosion.

Request for a quoteResults for

Cooling belt - Import exportNumber of results

10 ProductsCompany type