- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyors accessories

Results for

Conveyors accessories - Import export

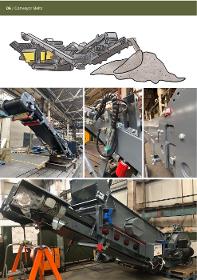

GSW SCHWABE AG

Germany

the conveyor system TB2000 distinguishes itself through its compact design. A modular scaling allows quick delivery while serving a great variety of applications. large belt widths and higher capacities allow removal of scrap also with bigger presses. the nuts on the sides can be used problemfree for tightening the directional controls or other accessories

Request for a quote

NOVELTY STEEL

Turkey

Belt Conveyor systems consist of several key components with each playing a crucial role in the conveyor’s operation and efficiency. Novelty Steel supplies; *Belt (Belt Carcass) *Conveyor Idlers ( Rollers) *Pulleys *Drives *Other Components

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

With PVC pipe and head, with steel tube and PVC head. They are mounted vertically with sliding guide functions; horizontally for special applications such as the mounting for tangential belts in motor-driven conveyors through driven base rollers or rollers with pulley for flat belt. With plastic wheels on steel axles, assembled in sequence, they are used as an alternative to tapered rollers in gravity curves for the handling of packages with a flat supporting surface and light loads. The wheels can be individually assembled, fixed on flatbeds by means of suitable brackets, in correspondence with exchanges between curves and tracks with idlers, in conjunction between tracks with ortogonal motor-driven rollers or with the function of guide-abutment of packages.

Request for a quote

SUNALA LIMITED (TRAVTEC GROUP)

United Kingdom

The Travtec range of conveyor accessories has been increasing the efficiency of product manufacturing for over 25 years. Whether you want to code on the underside of aerosol or beverage cans, cosmetic jars and bottles our Diverter and Paratran are designed to operate with your CIJ printer or laser to provide a clean, readable code at any line speed. Our Mini-press, presses the lids & caps onto bottles & jars after hand or mechanical application, preventing wrist strain and other potential injuries. To compliment the machine, our Caplicator can apply the caps & lids before pressing them onto the container. For Tamper-Evident sealing, Our Tiny Tampino Tabletop label applicator is widely used around the world for product security. Our Labelino range of label applicators are used for applying print &self adesive labels to flat & round containers. For labelling or printing corrugated cases the Travtec TR-1000 Casefeeder feeds flat corrugated cases vertically to give 4 side access

Request for a quote

NOVELTY STEEL

Turkey

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In industrial environments a combination feeding hopper and dosing belt conveyor is a frequently utilized system for regulated material feeding and dosage. Before raw materials or bulk materials are fed onto the belt conveyor they are first stored in the feeding hopper. In order to enable accurate material distribution and consistent dosing it guarantees a constant and continuous supply of materials to the dosing belt conveyor. Transporting and dosing materials at a regulated rate however is the job of the dosing belt conveyor. The technology is appropriate for batching mixing or processing operations that call for precise material dosing because it can control the conveyor belts speed and capacity to precisely dispense the required quantity of materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTT100 Track Stacker is an ultra-heavy-duty, versatile material-handling machine. Being a track-mounted stacker, it has unrivaled mobility and adaptability, suitable for large volumes of materials like aggregates, sand, gravel, and soil to move on difficult terrains. With the track-based system, the PTT100 can manage rough, uneven, or soft surfaces with ease; it is perfectly suited for mining, construction, and recycling industries. Be it an uneven job site or the need for efficient stockpiling in unapproachable areas, the machine is engineered for top performance in demanding conditions. Besides mobility, the PTT100 is designed to stack material efficiently for maximum storage space with minimum frequency of material handling. This saves immensely and enhances productivity in operations that require large-scale stockpiling. Coupled with other machinery, like crushers and conveyors, it becomes an integral part of a complete material handling system.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTT60 Track Stacker is a high-performance track-mounted stockpiling machine designed for conveying and stocking large volumes of material. Because of track-mounted mobility, this would be easy to maneuver into position and operate in difficult terrains. That makes the PTT60 ideal for industries such as construction, mining, recycling, and agriculture, where heavy material handling and stockpiling are at an all-time high. With the track system, this machine will have no problem operating on muddy, slippery, or uneven surfaces-it will be very manoeuvrable. The big stockpiling capacity translates to less number of operations, hence saving time on site. Besides the transport of materials, the PTT60 maximizes space utilization for the purpose of storage. The design allows higher and more accurate stacking to optimize space and reduce material handling costs. The machine can work with crushers, screens, and conveyors in conjunction with one another to enhance all operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Automatic Distribution Conveyor possessing a Shuttle Type design is a sophisticated material handling system applied in warehouses, distribution centers, and manufacturing facilities. This equipment is primarily engineered to automate the sorting and distribution of items along a conveyor line. Unlike the other systems, this system has a shuttle mechanism that runs across the entire width of the main conveyor, picking items up and transferring them transversely to specific offloading locations. It operates independently of the main conveyor and can handle the accurate transferring of items depending on their destination, size, weight, or any other parameter that needs to be considered. Incorporate this shuttle mechanism to improve the total efficiency and accuracy of the system in handling materials and automate the flow of goods through various processes from processing to shipping.

Request for a quote

ACEMAL NV

Belgium

Conveyor belts Accessories Watch our production lines on video Armoires de fermentation We create fermentation chambers according to the needs of the customer. They are equipped with rotating shelves in stainless steel and are available in all sizes.

Request for a quote

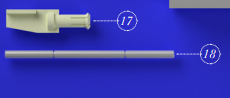

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Joining tubes can be used to create a hybrid join between a full strand weave and the use of joining clips. A single strand is cut into smaller single space sections, which are woven into the belt and joined together by crimping a stainless steel joining tube onto the adjacent wire sections. This method maintains the belt strength of a full strand weave while eliminating the distortion that occurs during the weaving process. It is important to consider whether joining tubes could mark product or have hygiene implications when choosing this method.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt Company offers a range of belt maintenance tools for easy removal, repair or installation of metal conveyor belts. All tools are packaged in a reusable storage sleeve to help maintain the tools precision and cleanliness.

Request for a quote

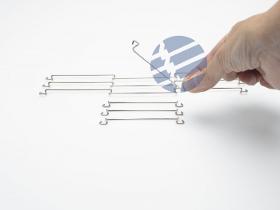

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Belt clips are used for joining the belt during installation and for making fast minor repairs to the belt. They are available in one space and three space units. If you would like clips, these should be ordered at the same time you place your belt order.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Using EZ-Splice® belt joining strand during installation will dramatically extend your belt life! Belt installations that are rushed and improperly made are often the cause of belt breakage and downtime. EZ-Splice® is a pre-formed, pre-bent joining strand that requires no bending or weaving during installation. This helps to prevent any weak spots in the belt joint.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CK 412 is an automatic saw blade machine which is ideal for cutting operations of the PVC glazing beads at 45°. Adjustable saw blade feeding speed Pneumatic saw feed by pushing button Equipped with 2x pneumatic vertical clamps Automatic return to start point of the process Twin blade design 8 glazing beads can be cut simultaneously using single mold without problems STANDARD ACCESSORIES 1x Ø 200 and 1x Ø 103 mm saw blades KN 152 roller conveyor Air gun OPTIONAL ACCESSORIES Clamping device for special glazing beads Additional saw blades Digital Roller Conveyor with Automatic Stop (SKN 301) SKN 300, SKN 450,SKN 600 conveyor SKN 301, SKN 451, SKN 601 conveyor Videolar TECHNICAL SPECIFICATIONS 1200 W x2 400V AC 50~60 Hz 3.000 D/dak. RPM D1:103 mm D2:200 mm d:30-32 mm 6~8 Bar 35 Lt. / dak. 54x113x124 cm 168 kg 134 kg

Request for a quote

ELMOR

Switzerland

Counting machine elmor C1: accessories and variants Conveyor bowls The parts to be counted with the elmor C1 counting machine are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Dual Product Outlet The dual product outlet can increase the productivity in Preset Mode (= repetitive batch counting). Each time when a batch is counted, the outlet switches to the other side and the counter restarts automatically. The dual discharge chute is intended to be used for counting crop seeds or corn, which are filled directly into bags, but can also be used for other seeds with 1mm diameter or more. Automatic Seed Weight Sorter Each single seed of a lot is automatically placed on a scale. The Automatic Seed Weight Sorter measures the weight of each seed and compares it with one or several limits. According to the result of this comparison, the weighed seed is then transferred into two or more containers. So the parts can weighed and sorted either into good and bad parts or into several weight classes. Filling Carousel The C1 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Filling adapter Adapter for small containers, bottles, laboratory tubes etc. This adapter allows dustfine and costly parts to be filled directly into containers. The C1 seed counter can be started only when a container is present.The filling adapters are manufactured individually on request. Dust Cover If specific small parts are processed, a dust cover can be of advantage. This is for example the case with pharmaceutical components, implants or with parts that need to be processed in a protective atmosphere. In this case, nitrogen or other gases or may be introduced through the dust cover. Ionizer When transporting small parts in the vibrating conveyor bowl there is a risk that the parts can become electrostatically charged. The correct separation of the charged parts becomes difficult. With an ionizer, the charged parts can be neutralised, shortly before leaving the bowl, in the region of the sorting element. The ionizer used in elmor C1 seed counter is manufactured by a specialized company, which is represented worldwide. The head of the ionizer is attached inside of a dust cover. Receipt Printer for Seed Counter elmor C1 The result of each completed count is printed automatically. The printing is done in plain text and bar code. During sample preparation or inventory counts many customers have expressed a wish to be able to print the determined number immediately. This can be done with this new accessories for the C1 counter. Faulty manual recordings are obsolete. Technical data: Paper: standard thermopaper rolls, 80mm width. Internal cutter, label length 64mm Barcode: Code 128 (International Standard ISO/IEC 15417), other codes on request Power supply: 100 – 240V, 50/60Hz The C1 seed counter must be equipped with an elmor printer interface board Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of the counting machines elmor C1, C3 or CX Intermediate storage container of counted parts When a seed counter is combined with a packaging machine, it may be advantageous to add a container for synchronization therebetween. When the counting operation has finished and the packing machine is ready, a discharge flap is opened briefly, so that the content of the container is discharged into the packaging machine. Then the flap closes and the counting machine begins with a new operation. As a result, the waiting time that would be needed before a packaging machine is ready for the next lot can be greatly reduced, allowing a shorter cycle time. Depending on the task different volumes can be realized.

Request for a quote

GURTEC GMBH

Germany

Reduce downtime and maintenance requirements with ROXDUR wear products. ROXDUR is a wear plate product that utilises the latest technology to provide a long lasting and durable wear solution suitable for heavy duty and medium duty applications. ROXDUR products can significantly increase the life of your fixed plant equipment. Our innovative manufacturing processes ensure a superior wear product that will save you time and money in the long run. ROXDUR wear plates are designed with the highest quality and years of expertise. Our pre-designed products can also be customised to fit your requirements. ROXDUR uses a unique composite material* that combines extreme hardness to minimise abrasive wear and iron matrix technology to absorb impact. The metallurgical bond between the cemented carbide and iron matrix gives a composite material with very high-quality adhesion to the cemented carbide. *patent pending MATERIAL CHARACTERISTICS Combining extreme hardness with shock resistance

Request for a quote

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Osmak manufacture standard and costum designed 2 or 3 parted conveyor stations with highest quality materials in according to related international standards. Please do not hesitate to contact us for more information.

Request for a quoteResults for

Conveyors accessories - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Conveyor belts (13)

- Grids, gratings and wire mesh (4)

- Conveyor systems (3)

- Stackers (2)

- Bearings, roller (1)

- Bending - steels and metals (1)

- Bulk materials for construction (1)

- Machine tools, metal shaping - parts and accessories (1)

- Packing and packaging - machinery and equipment (1)

- Plates, perforated - ferrous metal (1)

- Turning - steels and metals (1)