- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control lines

Results for

Control lines - Import export

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

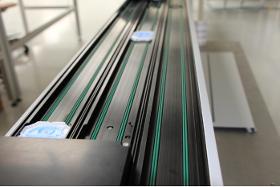

Carrier – aluminium milling part for control line. Our machined parts have become an important part of: ●control lines, ●automatic assembly, ●robotic grippers, ●independent stations, ●pallet systems, ●pneumatic systems and ●production lines. Technically advanced CNC processing services with 3- and 5-axis CNC milling work allow us to meet clients’ specific requirements. Our focus is on quality manufactured and quick delivery times while keeping a competitive pricing level.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Oil and gas extraction projects increasingly require the use of long, continuous lengths of corrosion-resistant control lines. You’ll find our high-performance tubes successfully used in the most aggressive subsea and downhole conditions. Our control line tubes enable downhole valves and chemical injection systems to connect with remote and satellite wells, for both fixed and floating central platforms. Please note that we have a minimum order value of £10,000.

Request for a quote

FEMIA INDUSTRIE

France

Right when your products arrive at the plant, receiving, the beginning of the processing process, is a key element in the performance of your production line. Indeed, the receiving hoppers must be adapted to your unloading system and this first step contributes substantially to the smoothing out of the flows in the preparation line. The receiving solutions that we offer are intended for the unloading of the product coming from the field by avoiding losses of raw material, by preserving the integrity of the latter and by ensuring a continuous and controlled flow rate on the line Hoppers – whether underground or not – with a system of elevators, manual load hoppers (…), our range of receiving machines allows us to set up a solution in line with the method of unloading used (truck, bag, tips, containers.)With a concern for preserving our customers’ products, we have developed hoppers that are specifically designed for certain vegetables according to their shapes and weights.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work services are fully adapted to meet your facilities maintenance and safety needs : replacement and/or modification of walkways installation and/or modification of ventilation ducts manufacture and installation of floors and access doors on production lines welding of reinforcements on to machine frames modification of fabric drive systems, presses, cylinders and rollers modification of pneumatic and hydraulic control systems installation of conveyor lines mechanical protective equipment: grids, gratings, walkways and doors machine guarding: stainless steel, steel, etc. We guarantee a highly flexible and adaptable service, while meeting all of your production requirements and maintaining the configuration of your existing facilities.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The dipping system which is one of the other methods is produced with a robot or crane controlled. The systems are equipped with the most efficient heating, ventilating and PLC control equipment. In our dipping lines manufacturing, AISI 304- AISI 316 stainless sheets of steel and polypropylene are used. The system should be selected according to the shape of the part, the area to be used and the corrosion resistance. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation, our company produces cold dipping lines as well as natural gas heated, electric heated, liquid fuel heated and water heated dipping pre-treatment lines according to the energy source that is planning to be used.

Request for a quote

PARSMEGA MAKINA

Turkey

It has wide usage opportunities in all areas where engine use is intense, such as production lines, factories, smart buildings, treatment facilities, pump stations. Our panels are designed considering the ease of operation and maintenance of MCC, with standards-compliant solutions for production lines and control that require process control. Our project support, the solutions we produce for control systems with conventional or "process controllers", our knowledge and experience are an important privilege we offer to our customers. Using the right equipment or system in the right place and our complete solutions made with quality equipment are part of our tradition of achieving important criteria such as operational safety and investment efficiency for the benefit of the end user.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Our video combi cables consist of several stranded video coaxial cables or a combination of video cables and power supply line. The cables combined with power supply are used when a separate power supply for the camera (control line, lighting etc.) is not possible at the location of use.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Our video combi cables consist of several stranded video coaxial cables or a combination of video cables and power supply line. The cables combined with power supply are used when a separate power supply for the camera (control line, lighting etc.) is not possible at the location of use.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Our video combi cables consist of several stranded video coaxial cables or a combination of video cables and power supply line. The cables combined with power supply are used when a separate power supply for the camera (control line, lighting etc.) is not possible at the location of use.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Our video combi cables consist of several stranded video coaxial cables or a combination of video cables and power supply line. The cables combined with power supply are used when a separate power supply for the camera (control line, lighting etc.) is not possible at the location of use.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

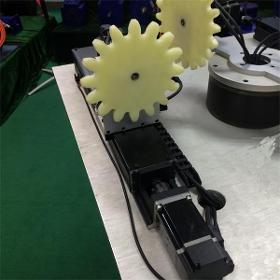

- Standard shuttles 48x48 mm - RFID technology - SMS management by routing software OMS - Mainly used by watchmaking sector and microtechnology - Intelligent conveyor for industrial automation with production traceability Examples: - Assembly line for balance-springs - Assembly line for barrels and the control - Flexible transfer line

Request for a quote

BURRE HYDRAULIK GMBH

Germany

6-way construction With leakage control Media: hydraulic (flow line/return line), cooling liquid (flow line/return line), natural gas, oxygen

Request for a quote

INFICON GMBH

Germany

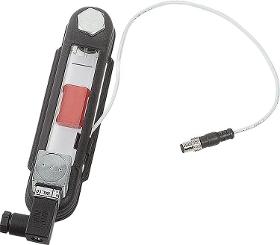

Sustainable solution for process measurement, control and data log Compatible to the wide range of INFICON active gauges, the new VGC50x series of active gauge controllers are able to monitor and data log the entire pressure range from 10⁻¹⁰ to 1500 mbar (10⁻¹⁰ to 1125 Torr) and the set point status. The new VGC50x Active Gauge Controller series is the advanced successor of the discontinued VGC40x series which was the 1:1 compatible product Leybold`s Center-Controller line Material-No Typ 230 002 Center ONE 235 002 Center ONE (USA) 230 004 Center TWO 235 004 Center TWO (USA) 230 003 Center THREE 235 003 Center THREE (USA) As the direct successor for these series the new and advanced VGC50x series is able to accept all INFICON Active Gauges Successor product for VGC40x Controller series 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 5×10 -4…1500 5×10 -4…1500 5×10 -4…1500 5×10 -10…1500 5×10 -10…1500 5×10 -10…1500 mbar, Torr, Pa, hPa, Micron, V mbar, Torr, Pa,...

Request for a quote

BIZERBA SE & CO. KG

Germany

Control of all labeling jobs from the ERP system Order processing software _orderProcessing.BRAIN retrieves entire labeling jobs from the ERP system in form of XML files and entirely autonomously controls price labeling lines via _connect.BRAIN. Labeling can be performed on a single-job basis with different items or on a per-item basis for different customers. All relevant data is called up by _orderProcessing.BRAIN and the actual production data is returned once the job is complete.

Request for a quote

FERPLAST SNC

Italy

The TRITONE labeller was made by dividing it into modules, so as to allow use in both horizontal and vertical positions and easy integration into the packaging lines. The control is entrusted to a microprocessor, which manages the pre-separation in mm. and regulates the speed from 0 to 30 mt. min. TECHNICAL FEATURES Stepper motor with variable speed from 5 to 30 mt./min. Maximum label width mm. 100 Minimum label width mm. 20 Maximum label length mm. 300 (higher on request) Minimum label length mm. 20 Label application delay via electronic setting Label application precision mm. 0.5 Label reel with internal diameter mm. 40-76, external mm. 300 max Rewinding roller for silicon paper recovery Variable reading photocell for label stop REFLEX photocell for product detection End of roll alarm (optional) Electronic control unit Switch Stroke counter with zero setting Protection fuses Potentiometer for speed adjustment of labeling head Power supply 220 V 50 Hz. Dimensions mm.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The innovative recuperation module from CIC acts as an energy-saving valve and control module directly in the pneumatic circuit. Functionality : It is installed directly on the consumer - e.g. on the pneumatic cylinder or in the pneumatic control circuit. The recuperation valve with its integrated control electronics measures and regulates the air consumption and feeds used compressed air back into the working cycle for reuse. Advantages : Reduction of compressed air consumption by up to 80%. Increase in efficiency of the plant. Smart monitoring and diagnostics of the pneumatic system with numerous evaluation options and control in line with Industry 4.0. Detection of leaks and irregularities. Delivery for predictive maintenance data. Avoidance of downtimes. Simple control software and wireless transfer from PC.

Request for a quote

BORSIG GMBH

Germany

Today’s demand for increased efficiency and flexibility that comes along with higher temperatures, increased pressures and high cycling requires specific engineered valves. We design and manufacture high quality trunnion mounted ball valves tailored to your specific control processes by using customized control discs. Our control valve product line is engineered to suit very high differential pressure applications giving you an exceptionally high rangeability for your plant operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TURKISH MANUFACTURERS UNION

Turkey

GA Home Appliances started its commercial activities in 2010 in Kayseri. Our company which ic active in electrical household appliances and metal furniture sector.Our product ranges includes electrical round ovens, grills, trays etc. Our company has presented these popular home decoration product with esthetic visuality to the global market. Our products have ergonomic and safe designs. Our experienced staff control production line under 100% quality process.GA Appliances has a wide marketing field in Turkey. Our most important target is to increase our brand awareness without compromising on our quality process, to be in global markets and to respond all the needs of every home with our products. info@turkishmanufacturersunion.com Whatsapp-Phone: 0090 530 137 21 45

Request for a quote

NORELEM FRANCE

France

Housing fibreglass reinforced thermoplastic polyamide. Sight glass thermoplastic polyamide. O-ring and flat seal NBR. Reflector PVC. Float plastic. Screw and nut, steel. Version: Housing black. Sight glass crystal clear, high mechanical stability, non-ageing. Reflector white. Float red, with magnetic element. Screw and nut electro zinc-plated. Note: The oil level gauge not only enables the oil level to be viewed but also recorded using a REED switch. In addition, the oil level gauges can also emit an electric signal if the temperature of the liquid inside the container reaches the threshold of 70 °C. As soon as the float element approaches the selected minimum value after the circuit has been closed, the system emits an electric signal. The sensor is located on the housing and its height can be adjusted in line with the control requirements for the oil level. The minimum level is ca. 35 mm from the centre of the lower fastening screw.

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

KUZEY GLOBAL

Turkey

Synchronized forming and cutting by tilting movable lower platen to 80 degrees Sheet pitched by double toothed chains and move on abrasion resistant slide plates; Lengthened pan design allows to reach optimum forming heat without using pre-heater machine Upper and lower Mold ; heats control by indivudial Thermoregulation device Fine adjustment for mold by electric drive. Traversing and tilting moving system of mould PLC for control the line operation and supervise working parameters Opportunity to set one or more forming cycles without cutting by pneumatic drive High production capacity with resistant to high speed Strong and vibration free main body Double inlet- outlet system for fast cooling by increasing water discharge. Energy analyzer which gives amount of the electric consumption Cutting adjustment possible by digital meter ,controlled by PLC. Plug asist motor

Request for a quote

KUZEY GLOBAL

Turkey

Synchronized forming and cutting by tilting movable lower platen to 85 degrees Sheet ; pitched by double toothed chains and move on abrasion resistant slide plates; Precise heater control for upper and lower pan. Upper and lower Mold ; heats control by indivudial Thermoregulation device Fine adjustment for mold by electric drive. PLC for control the line operation and to supervise working parameters Non-stop working capacity with easy maintain mechanical system. Safety system ensured by sensors such as sheet sagging , pressure drop,door ajar situations Water and Heat balance measure sensors for mold which can be control by PLC system Energy analyzer which gives amount of the electric consumption Cutting adjustment possible by digital meter ,controlled by PLC. Plug asist motor and plug speeds all controlling by PLC suitable to put variotions of movement to plugs to plugs,start slow go fast end slow etc

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The MPERIA 8″ is the most compact controller in the MPERIA product line. This controller manages one printing technology. Upgrades are available that allow for expanding functions including the number of controlled devices.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

I/O modules are a fundamental component in industrial automation. They act as an interface between the control unit and the operational devices of the production line, facilitating precise control of complex processes. Our products have a CAN interface, so we support the CANopen, CANopen FD and J1939 protocols

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Experience the pinnacle of marking and coding efficiency with the MPERIA Controller. Seamlessly switch messages in seconds, enhance mark quality, and centralize coding control on your production lines regardless of equipment manufacturer. With over 170 years of expertise, we ensure ongoing support, making us your reliable partner today and beyond. Legacy Controller Challenges Companies grappling with outdated, inflexible marking systems face significant challenges in streamlining their product, case, or pallet marking processes. These systems are difficult to use, lacking automation features, and hinder seamless integration into existing production environments. The absence of user-friendly interfaces and manual code changeovers lead to increased errors, bottlenecks, and inefficient operations, resulting in unnecessary labor hours and costly recalls. There is a pressing need for an easier-to-use, automated marking solution that enables efficient integration, improves

Request for a quote

KMC GROUP - MEKO METAL

Turkey

As KMC Group, we serve to automotive main industry, furniture, domestic appliance, steel goods, decoration, heating & cooling, air conditioning, civil works & steel construction, scaffolding profiles, heated towel rack, solar energy systems, and agricultural irrigation & greenhouse industries by specially produced profiles with MEKO Brand. We continue to our stabilized commercial life for over half century, with annually 150 thousand trade capacity of Carbon Steel, Galvanized, Hot Rolled and pre-painted on demand and following the latest technology in order to serve you better. We maintain our quality perspective by performing physical & chemical tests in our own in house laboratories and R&D center, from raw material to finished products, using EC (Eddy Current), leak proof test, zinc spray coating on welding point and internal deburring processes. Your special cut to length requirements can be done in our computer controlled CNC and multi saw lines.

Request for a quote

GABELLA MACCHINE SPA

Italy

It is a special slitter with Numerical Control, different from all the others available on the market, with a variable number of slitting heads, which include in one single body the upper and lower blades. This allows to easily adjust the clearance between the blades (now also automatically) and to reduce the wearing. The characteristic that makes this slitting group original and extremely efficient is the system of changing the slitting widths, without manual intervention of the operator. The slitter can be managed by N.C., so from the line control-board, by remote control, or even by a PC interfaced to our customized softwares: GA.GE. or GMDesign.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Loss in weight gravimetric feeder for extrusion lines automatic control, it controlls the haull-off speed and weight per meter of pipes during extrusion process.

Request for a quote

PJM MECHANICAL CO.,LTD

China

CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing,paper board transport,textile print and dyeing,artificial chew simulator,blood tester,CAT scanner,DNA tester,pacemeter,robot

Request for a quoteResults for

Control lines - Import exportNumber of results

113 ProductsCountries

Company type

Category

- Wires and cables, steel (11)

- Cables & Networks (4)

- Food industry packaging machinery (4)

- Precision mechanics (4)

- Driveshafts and micro-motors - electric (3)

- Alarms - security devices (2)

- Copper wires and cables (2)

- Hygrometers (2)

- Labelling machines (2)

- Measurement - Equipment & Instruments (2)

- Milling - steels and metals (2)

- Packing and packaging - machinery and equipment (2)

- Pipes and tubes, stainless steel (2)

- Printers - computer (2)

- Steels and metals - machining (2)

- Automation - systems and equipment (1)

- Testing equipment (1)

- Aerospace and aeronautics - construction (1)

- Brakes, servo-brakes and accessories (1)

- Catering - machinery and equipment (1)