- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- complex parts machining

Results for

Complex parts machining - Import export

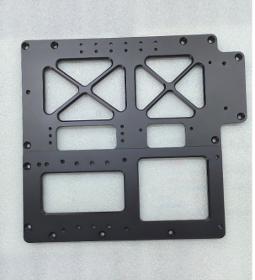

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in machine,the fuction is the support. These parts were made by aluminium,afte CNC machining milling.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg offers the highest-quality precision machined mill-turned parts that are engineered to fit your specific application needs. Our CNC mill-turn machining utilizes the latest technology and the highest level of craftsmanship to create parts with the perfect fit and accuracy for any project. What is Mill-Turn Machining? Mill-turn machining is a type of precision CNC machining that uses advanced machines to create a variety of complex parts. The machines used for mill-turn machining combine both milling and turning operations into one setup. Capable of performing multiple simultaneous operations such as drilling, milling, and tapping, mill-turn machining is ideal for parts that require complicated geometries. We Specialize In: Multi-Axis Machining Milling Turning Thread Milling Drilling Tapping Slotting Chamfering Common Applications for Mill-Turned Parts is automotive, medical, aerospace, and food & beverage, etc. Contact us: sales@mxmparts.com

Request for a quote

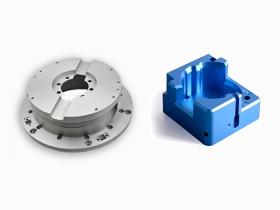

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Steel custom milling parts became part of pallet systems for industrial automation. Our main activity is production of individual custom components, from less demanding to very demanding and complex ones. Machined parts are used in: -the medical fields, -electronic equipment, -automotive industry, -aerospace, -intelligent robotics and -Industrial automation. Specializing in various sectors of development companies, we offer advanced custom parts, working with materials like aluminium alloys, plastic, metal and steel. Our technically advanced CNC processing services allow us to meet clients’ specific requirements and by our client's request we provide surface treatments.

Request for a quote

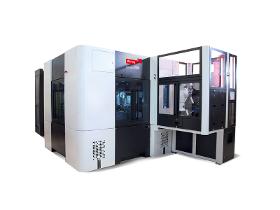

STARRAG GMBH

Germany

A 4station transfer machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g 4 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

A standalone monostation machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Material: ASTM, JIS, DIN, BS, iron, steel, aluminum, manganese, carbon steel, stainless steel, etc. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

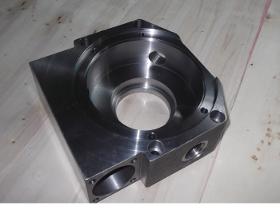

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Steel Machinery Parts manufactured on CNC machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

brass knob manufactured by CNC turning and milling on sliding head multi-axis CNC lathe material: brass HBi59-1 size: diameter 11+/-0.05 mm, 8.65+/-0.05 mm, length 28.8 +/- 0.1 mm inner thread: M3xP0.5x10 With sliding head multi-axis CNC lathes, we are capable of producing complex parts requiring turning, milling, drilling, tapping, broaching etc in one setup.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

CNC Machined Parts material: aluminium alloy Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

spindle end housing manufactured by CNC turning and milling 4 thread holes chamfered on both sides, thread grade M3.0 free of burrs cap end external diameter: 30.50 +0.05/-0.00 mm bottom end external diameter: 14.60 +0.10/-0.05 mm height: 17.50 +/- 0.03 mm material: aluminum alloy ASTM 6061-T6 With sliding head multi-axis CNC lathes, we are capable of producing complex parts requiring turning, milling, drilling, tapping, broaching etc in one setup.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

inner inlay tube size: end outer diameter 19.20 +0.04 mm, end inner diameter 19.00 + 0.04 mm height: 70 - 0.15 mm side hole diameter 11.70 - 0.05 mm 2 grooves width: 3.3 mm, 5.3 mm material: brass ASTM C28000 packing: individually placed in a plastic tray, then into carton manufactured by CNC turning and milling on sliding head multi-axis CNC lathe

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom small machine parts by CNC Turning & Milling for worldwide customers. Usually we process small mechanical parts, will give priority to composite processing, that is, turning, milling, drilling, wire cutting, and other processes are carried out separately.This kind of processing method is a bit cheap, suitable for products with low quality requirements. And some small mechanical parts that pay attention to dimensional accuracy and concentricity need to be processed by turning and milling compound CNC equipment, and smaller products can be processed by walking centrifuge. Hope you are interet in our CNC turning & machining services, if you have any machined parts need to be custom produced in China, welcome send your drawing or sample to us, we shall quote a best price to you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, we have all kinds of machining equipment, can provide a variety of processing methods to meet the machining of various steel parts. As a professional Steel Machined Parts supplier from China,we can custom producing all kinds Carbon & Stainless steel turned parts,Copper & Brass turned parts,Aluminum Turned Parts & Machined parts, such as tube coupling, hose coupling, shaft, pipe joint parts, hose connectors & transition connectors, copper machined tube, flange,bushing, knighthead, pedestal, Piston Rod, insert long pin, Dowel Pin, Drive Pin & Rod,ball head bolt, long rod machined parts, long thread tube parts, nonstandard thread bolt & nut,Extension Rod, etc. Widely use for all industries. China Metal Parts manufacturer custom produce Steel Machined Parts according to customer’s design, provide CNC Turning, Milling, Tool Machining Services, Welcome send inquiry to us !

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a old metal parts manufacturer from China, custom tube machined parts according to customers' design or samples. Tube machined parts means the raw material of the parts are made from tube,such as welded tube, seamless tube. The material can be carbon steel, stainless steel tube,aluminum tube, brass tube or copper tube. There are a variety of processing amplification, roughly divided into cutting, flattening, expansion, turning, milling, drilling and so on. If you have any tube machined parts need to be customized in China, welcome contact us for a quote.

Request for a quoteResults for

Complex parts machining - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (7)

- Milling - steels and metals (4)

- Steels and metals - machining (3)

- Bending - steels and metals (1)

- Import-export - mechanical engineering (1)

- Machine tools - metal machining (1)

- Mechanical engineering - custom work (1)

- Plastic products for engineering (1)

- Radiators, engine (1)

- Rolling machines (1)

- SMALL METAL PARTS (1)