- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cold rolling line

Results for

Cold rolling line - Import export

SCHNELL SPA

Italy

The Combidrive MO is a cold rolling line with single horizontal drawing capstan for the production of smooth and ribbed wires in bars from Ø 4 to Ø 12 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Wire is rolled to reduce the section and if necessary ribbed, then straightened and cut according to the different lengths scheduled. Rotating cut system to ensure continuous production Max. pulling speed (straight bars production) 6 m/s Max. pulling speed (coil production) 8 m/s Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s)

Request for a quote

SCHNELL SPA

Italy

The Coldrive MO is a cold rolling line with single horizontal drawing capstan for the production of smooth and ribbed wires from Ø 4 to Ø 16 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 8 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous vector motor" low consumption, high power User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 3MV 3,4 10 mm (16 m/s) 4MV 3 8 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

The “Coldrive” 4MV is a cold rolling line with multiple vertical drawing capstan for the production of smooth and ribbed wires from Ø 3 to Ø 8 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 16 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 3MV 3,4 10 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s) MO 4 16 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

The “Coldrive” 3MV is a cold rolling line with multiple vertical drawing capstan for the production of smooth and ribbed wires from Ø 3,4 to Ø 10 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 16 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 4MV 3 8 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s) MO 4 16 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

The “Coldrive” 2MV is a cold rolling line with multiple vertical drawing capstan for the production of smooth and ribbed wires from Ø 3,4 to Ø 12 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 12 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Line at 1 or 2 passes with single vertical drawing capstan MV 4 12 mm (12 m/s) Multipass line and multiple vertical drawing capstan 3MV 3,4 10 mm (16 m/s) 4MV 3 8 mm (16 m/s)

Request for a quote

SCHNELL SPA

Italy

The Coldrive MV is a cold rolling line with single vertical drawing capstan for the production of smooth and ribbed wires from Ø 4 to Ø 12 mm. This cold drawing line is completely modular and the rolling process is made through drawing capstan and rollers cassettes for rolling/profiling. Driven by electric asynchronous servomotors digitally controlled. Max. pulling speed 12 m/s (higher speeds on demand) Compact Layout Highly customizable "Asynchronous servomotor" low highpower consumption User friendly software for cold rolling process management Web Teleassistance Other cold rolling lines Multipass line and multiple vertical drawing capstan 2MV 3,4 12 mm (12 m/s) 3MV 3,4 10 mm (16 m/s) 4MV 3 8 mm (16 m/s) “Coldrive” MO with single horizontal drawing capstan MO 4,5 12 mm (8 m/s) MO 4 12 mm (8 m/s) MO 4 16 mm (8 m/s)

Request for a quote

SCHNELL SPA

Italy

STRETCH DRIVE MO is a Cold Rolling and Stretching Line with single horizontal drawing capstan for the production of both smooth and ribbed, colddrawn wire with low carbon content and hot rolled high ductility ribbed wire. Stretching Process Stretch Drive MO 6 16 mm (8 m/s) Cold Rolling Process Stretch Drive MO Cold 1 4,5 12 mm (8 m/s) Stretch Drive MO Cold 2 4 12 mm (8 m/s)

Request for a quote

TECNO IMPIANTI SRL

Italy

Unlocking the roll-holders nut is not an easy thing to do. The unlocking device Mod. DSR is very useful and practical and is of great help to the operator.

Request for a quote

TECNO IMPIANTI SRL

Italy

On our cold rolling lines, at the exit of the last pass, before the wire is taken-up on the vertical or horizontal spoolers, it is possible to install a strain relieving unit with rolls, Mod. SR. The strain relieving units with rolls manufactured by Tecno Impianti are available in different configurations, according to the type of cold rolling line on which they are installed.

Request for a quote

TECNO IMPIANTI SRL

Italy

After the descaling operation, the wire passes through a lubricant dispenser. Tecno Impianti designs and manufactures the lubricant dispenser Mod. DL in the version with two screws for high speed cold rolling lines.

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufactures mechanical descalers Mod. DM which are utilized for descaling the wire before the it is processed on our cold rolling lines. Our mechanical descalers are available in different configurations, according to the wire diameter and the application which has to be run. The descaling rolls are manufactured in tungsten carbide.

Request for a quote

TECNO IMPIANTI SRL

Italy

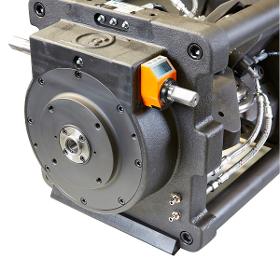

The cold rolling cassettes Mod CRC are utilized for executing the rolling and profiling operations on the wire, for production of smooth and ribbed wire. Strongly-built and innovative in their design, they permit to reduce the time needed for installing the rolls. These cassettes do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. By having one set of cassettes in operation and a second set off-line, being prepared with the rolls for the next application, the downtimes are reduced. When a production change is needed, the operator just removes the first set of cassettes from the cold rolling line, replaces them with the second set and start immediately to work.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR6014 is equipped with an horizontal bullblock with one pass and is used for the production of smooth or ribbed wire from 6.0 to 14.0 mm at a max speed of 8 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, a rolling/profiling cassette, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line Mod LLR4012 is utilized for production of smooth and ribbed wire with finished diameter 4,0 – 12,0 mm., at a maximum working speed of 12,0 mt/sec. Inside one single structure there are installed the mechanical descaler, the lubricant dispenser, the cold rolling cassettes, the vertical bullblock with 2 passes, the strain relieving device. The descaling unit Mod. DM14 is equipped with 6 rolls with insert in tungsten carbide, an air-blower and a tank for collection of the scales. The lubricant dispenser Mod. DL14 has two cochleas, one vertical and one horizontal. The cold rolling cassettes Mod. CRC150-30-33 are strong-built and do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. The vertical bullblock Mod. MV14 can work with one or two passes. The double pass is necessary to obtain the diameter 4.00 mm.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line Mod LLR4010 is utilized for production of smooth and ribbed wire with finished diameter 4,0 – 10,0 mm., at a maximum working speed of 12,0 mt/sec. Inside one single structure there are installed the mechanical descaler, the lubricant dispenser, the cold rolling cassettes, the vertical bullblock with 2 passes, the strain relieving device. The descaling unit Mod. DM14 is equipped with 6 rolls with insert in tungsten carbide, an air-blower and a tank for collection of the scales. The lubricant dispenser Mod. DL14 has two cochleas, one vertical and one horizontal. The cold rolling cassettes Mod. CRC150-30-33 are strong-built and do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. The vertical bullblock Mod. MV14 can work with one or two passes. The double pass is necessary to obtain the diameter 4.00 mm.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR3580 is equipped with a cold rolling machine with three passes mod TR600/3 and is used for the production of smooth or ribbed wire from 3.5 to 8.0 mm at a max speed of 12 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, three rolling/profiling cassettes, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR3560 is equipped with a cold rolling machine with three passes mod TR600/3 and is used for the production of smooth or ribbed wire from 3.5 to 6.0 mm at a max speed of 12 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, three rolling/profiling cassettes, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufactures a reel tilting unit with hydraulic command Mod. RR (maximum reel weight 3 Tons), which is installed on cold rolling lines where the wire is taken-up on horizontal spoolers. The tilting unit is utilized for bringing the reels in vertical position.

Request for a quote

TECNO IMPIANTI SRL

Italy

The vertical spoolers which take-up the smooth or ribbed wire coming from the cold rolling line, can be supplied also in the version Mod. BVD with double reel, for reducing the downtimes. Tecno Impianti designs and manufactures this machine both in the version with manual cut of the wire and with automatic blocking and cut of the wire. The double vertical spooler can be supplied in the version for 2 or 3 Tons reels

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufactures vertical spoolers Mod. BV for the the take-up on fixed or collapsible reels of the smooth or ribbed wire coming from the cold rolling line. The vertical spoolers manufactured by Tecno Impianti can work with reels of 2 or 3 Tons. It can be supplied as an accessory item also a steel strapping unit for the production of bound coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufactures horizontal spoolers Mod. BO for the take-up on fixed reels of the smooth or ribbed wire coming from the cold rolling line. Our horizontal spoolers are available in different sizes, according to the requested application. They can be integrated with a coil tilting unit, which is utilized for bringing the reel, after its extraction, into a vertical position

Request for a quote

TOK MEDICAL INDUSTRY AND FOREIGN TRADE LIMITED

Turkey

We produce High Quality Lead Sheets in our High Purity Ingots, Casting and Cold Rolling Line. Purity Rate is Minimum: %99.991-%99.998 Lead Sheets are Used in Many Areas From Exterior Cladding in Buildings to Cable Manufacturing. The Lead Plates we produce are produced in High Purity and in accordance with the Radiation Insulation and Safety Regulations. It is Accepted in International Standards as the Most Ideal Armoring Material to be Used as an Armoring Material Against Lead Radiation. Due to the fact that a large part of our production is exported, our products are produced in European Standards (CE) Annual Standard Controls Are Made Periodically, Our Documents Are Renewed Every Year.

Request for a quote

DOGA MAKINA

Turkey

Cold and hot drawing rolling mills, ring, roller, roller, disk or forming roller ring etc., called profile, wire, cable, electrode, iron, copper etc. The processing, manufacturing or, if desired, the correction of the rolling mills used in the drawing of materials such as profile, wire, cable, electrode, iron, copper etc. By performing highly precise cnc machining, both the quality of the product to be obtained is increased and the optimum benefit is provided to the customer by extending the life of the rolling mills used. By correcting the rolling mill tool, the customer's remanufacturing costs are reduced and the service life of the rolling mill tools is increased. Now these roller rings are processed and manufactured in the same quality in Turkey.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

State-of-the-art technology and extensive knowledge in the processing of steel characterise our location in Bad Salzungen, Germany. For us, performance means a wide range of cold-rolled steels of the highest quality at competitive prices, flexibility and a high degree of readiness to deliver while adhering precisely to the specified chemical and mechanical values. Surface finishing by electrolytic galvanizing and/or subsequent customisation of your goods are possible for us. We offer all our customers spooled materials with volumes of over 200,000 metres of metal strip per spool. This further development means a considerable advantage for our customers. Personnel-intensive set-up times and machine downtimes are avoided.

Request for a quote

ILK IHRACAT AS.

Turkey

Hot rolled and acid cleaned sheet is enriched by special processes. It reaches the desired thickness by reversible or tandem rolling. At this stage, the sheet is hardened, but becomes formable by continuous annealing or batch annealing. Tempering is applied to improve its mechanical properties. Quality control is ensured through tests and the tempered sheet is shipped in accordance with customer requirements. Cold Rolled Steel Sheet, which is obtained by re-rolling hot rolled and pickled products, has precise dimensions and high surface quality. Product Specifications: DC01, DC03, DC04, DC05, DC06 DC01EK, DC04EK, DC01ED, DC04ED HC260LA, HC320LA, HC380LA, HC420LA Application Areas: Automotive, White Goods, Machinery Manufacturing, Building Industry, Industrial Warehouse Solutions, Panel/Radiator, Fasteners. As Steeling.net, we bring together quality and diversity in cold rolled sheet and offer the highest level of value to our customers.

Request for a quote

MFO S.A.

Poland

Steel profiles and Mounting Rails applicable in central heating systems, ventilation system, fire protection systems and other light constructions. Hot rolled black steel complying with norm PN-EN 10025, PN-EN 10111(hot dip galvanization of ready elements according to norm PN-EN ISO 1461:2011) Cold rolled steel complying with norm PN-EN 10130 Galvanized steel for cold processing and construction galvanized steel complying with norm PN-EN 10346 steel resistant to corrosion complying with norm PN-EN 10088

Request for a quote

IMT MACHINERY

Turkey

Our line, equipped with a combinable set of rolls, can produce a wide range of “C, U, Z AND SIGMA ” profiles. The technological and design experience as equipment manufacturers has allowed us to develop a quick profile change system that reduces tooling setup time. With this system, we ensure greater flexibility of products and respect of delivery schedule, but at the same time respect and perseverance in the quality of the profiles. Because of our flexible punching systems, we develop profiles complete of custom punching. By integrating in our lines the special Flexi-Punch unit we can realize any punching pattern, tailored made according to the customer’s requests. The profiles can be realized also in structural materials (high strength) and have a pickled, galvanized or pre-painted finishing.

Request for a quoteResults for

Cold rolling line - Import exportNumber of results

31 ProductsCountries

Company type