- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coating ink

Results for

Coating ink - Import export

DEKORTECH GMBH

Germany

Heat transfer films for easy to peel heat transfers. ✔ High ink uptake ✔ Nice, matt finish ✔ Soft feel ✔ Great price ✔ Anti-static ✔ Thermally stabilized ✔ Hot or cold peel! Our instant-peel film for DTF (Direct to Film) printing is your best bet for a safe and easy process. It comes with many layers of coating which guarantee a great ink uptake and an easy release. Furthermore, the transfer film leaves you to choose in-between a quick hot peel straight after pressing or to peel it cold. The anti-static feature of this film makes sure that no hot-melt powder particle sticks to the unprinted area, giving you a clean transfer result. Additionally, the film is matt on both sides so that the print won't stick to the film once rolled up and to make sure, that it can be processed perfectly in your DTF printer and transfer press.

Request for a quote![3,3′-[(1-methylethylidene)bis(4,1-phenyleneoxymethyl)]](/filestore/vig280/opt/product/f9/63/product_3397e49e.jpg)

GM CHEMICAL CO., LTD

China

Product Identification Chemical name: 3,3′-[(1-methylethylidene)bis(4,1-phenyleneoxymethyl)] Synonyms: Bisphenol A dioxetane CAS No.: 105071-04-3 Molecular formula: C27H36O4 Molecular weight: 424.57 Melting point: 178 °C Specification Appearance: White powder Purity: 98.00%min by HPLC Moisture: 0.50%max Package Regular Packing: N.W 25kg fiber drum Sample Packing: 0.1kg-1kg foil bag Transport Information Classification: Non-dangerous goods HS Code: 2909499000 Status & Application Status: Industrial scale Application: Used for preparing UV coating, ink and resine

Request for a quote

GM CHEMICAL CO., LTD

China

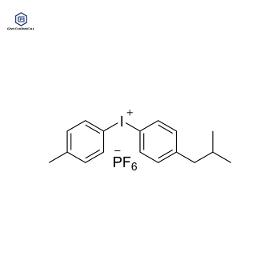

Product Identification Chemical name: 4-Isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate Synonyms: (4-Methylphenyl) [4-(2-methylpropyl)phenyl] iodonium hexafluorophosphate CAS No.: 344562-80-7 Molecular formula: C17H20IPF6 Molecular weight: 496.21 Density: 1.205 g/mL Specification Appearance: Yellow to brown liquid Content: 70.00%min Moisture: 0.20%max Transmittance (@ 450 nm): 80.00%min Transmittance (@ 500 nm): 90.00%min Clarity of solution: Clear Package Regular Packing: N.W 25kg or 200kg/Plastic drum Sample Packing: 0.1kg-1kg/Plastic bottle Transport Information Class 9 dangerous goods UN 3082 PG III HS Code: 2931900090 Status & Application Status: Industrial scale Application: 4-Isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate [344562-80-7] is Mainly used for UV coatings, UV inks, UV adhesives, Photoresist.

Request for a quote

GM CHEMICAL CO., LTD

China

Product Identification Chemical name: 2-Acetoxystyrene Synonyms: 2-Vinylphenyl acetate, Acetic acid 2-vinylphenyl ester CAS No.: 63600-35-1 Molecular formula: C10H10O2 Molecular weight: 162.19 Boiling point: 246 ℃ @ 760 mmHg Density: 1.070 g/mL Refractive index: 1.547 Specification Appearance: Colorless transparent liquid Purity: 98.00%min by GC Clarity (10% methanol solution): Clear Moisture: 0.10%max by KF Residual solvents: 0.10%max Polymerization inhibitor: 200-300 ppm Package Regular Packing: N.W 20kg/plastic drum Sample Packing: 0.1kg-1kg plastic bottle Transportation Information Classification: Non-dangerous goods HS Code: 2915390090 Status Commercial available Application 2-Acetoxystyrene [63600-35-1] has application in monomers for the production of resins, elastomers, adhesives, coatings, automotive finishes and inks, as well as in electronic materials. It may also be used as additives in elastomer and resin formulations.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

The Advantage is a revolution in the development of offset printing blankets for the printing industry. Sticky back blankets designed for Envelope printing. PROPERTIES Easy trouble free stencil preparation. Clean, edged, precision cutting, no spider legs. Gives uniform ink & coating transfer. Can be used with both conventional and UV curing inks. The blanket can be easily adhered / removed from different substrates, metal cylinder or blanket and easily repositioned after initial mounting. Once tightly cling provides excellent stability at high press speeds and resists most press chemicals. No residual adhesive remains on the press cylinder after blanket removal. APPLICATION Continuous F. Envelope Conventional Hybrid * The information on this technical data sheet is based on our general experience. The tests are carried out under controlled laboratory conditions. The information may change as conditions change.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MEDEK & SCHÖRNER GMBH

Austria

Multifiber coating and curing system for up to 12 optical fibers for inline operation Inline color coating and UV curing Coloring and UV curing up to 300 m / min Simultaneous coating of up to 12 fibersSuited for use in multifiber production lines operating at a maximum production speed of 300 m / minute and above. Coating unit with fiber entry guides, dust blower, and coating heads. Curing unit with one irradiator type M550, control electronics, cooling fan, and nitrogen flooding system including a nitrogen supply unit. FEATURES Simultaneous coating of up to 12 optical fibers. UV curing unit with one M&S designed irradiator. Suitable for production speeds of up to 300 m / min and above. Electrical heating system for coating heads. Pressure system for ink tanks.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

During printing and coating processes, so-called ink mist or particle mist arise in the outlet of doubleroll systems. This unwanted particle deposit results in lower product quality, high maintenance costs, increased ink consumption and the contamination of the environment. The formation of ink mist is very noticeable and annoying, particularly during coating and printing processes on substrates with non-absorbent surfaces (films, metalized substrates or composite films). A patented double-row DC plasma electrode is used to prevent this ink mist. This plasma electrode acts separately on both particle streams and ensures an optimal particle deposit. The electrode will be connected to the high voltage generator HSG61. The MISTING TACKER system is currently used for printing on metalized films and in silicone coating units (Wifag-Polytype).

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

During printing and coating processes, so-called ink mist or particle mist arise in the outlet of doubleroll systems. This unwanted particle deposit results in lower product quality, high maintenance costs, increased ink consumption and the contamination of the environment. The formation of ink mist is very noticeable and annoying, particularly during coating and printing processes on substrates with non-absorbent surfaces (films, metalized substrates or composite films). A patented double-row DC plasma electrode is used to prevent this ink mist. This plasma electrode acts separately on both particle streams and ensures an optimal particle deposit. The electrode will be connected to the high voltage generator HSG61. The MISTING TACKER system is currently used for printing on metalized films and in silicone coating units (Wifag-Polytype).

Request for a quote

STROJHIMTREJD

Russia

Pigment based on the rutile form of titanium dioxide. Provides excellent weather resistance and high gloss levels in paints and coatings, inks and plastics. The pigment is designed for use in the production of paints and varnishes based on various film formers, for industrial and decorative coatings, as well as inks and plastics, and for various other purposes. Main characteristics: Durability Easily wettable and dispersible High retention of gloss Excellent coverage Excellent depth of tone Gives high brightness to white colors Fields of application: Water-dispersion paints with any level of gloss For the manufacture of coatings used in aggressive environments Unplasticized and plasticized PVC Polyolefins Polystyrene and its copolymers Paper industry Plastics

Request for a quote

STROJHIMTREJD

Russia

The pigment is designed for use in the production of paints and varnishes based on various film formers, for industrial and decorative coatings, as well as inks and plastics, and for various other purposes. Main characteristics: Durability Easily wettable and dispersible High retention of gloss Excellent coverage Excellent depth of tone Gives high brightness to white colors Fields of application: Water-dispersion paints with any level of gloss For the manufacture of coatings used in aggressive environments Unplasticized and plasticized PVC Polyolefins Polystyrene and its copolymers Paper industry Plastics

Request for a quote

QUAY CHEMICALS B.V

United Kingdom

Aluminium Hydroxide 99.6% powder Chemical name: Aluminium Hydroxide , Aluminium Trihydroxide Chemical Formula: Al(OH)3 Molecular Weight: 78 CAS NO.: 1344-28-1 Physical Properties: Powdery substance Odorless Non-carcinogenic Contains thermal characteristic that provides translucency and whiteness to Solid surface material Non-smoking Low-toxicity Halogen-free Flame retardant Applications: Aluminium Trihydrate is used in various industries as: A raw material in the production of Aluminium chemicals A raw material in the manufacture of glass and glazes A raw material in catalyst production A flame retardant and smoke suppressant filler in plastics (for example: Cables, rubber products and carpet backing) A raw material for fertilizers, and fiber cement board products An extender and bodying agent in paper, solvent- and water-borne paints, UV curable coatings, inks, and adhesives A polishing and cleansing agent Mould wash and separating agent

Results for

Coating ink - Import exportNumber of results

12 ProductsCompany type