- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc machining pom parts

Results for

Cnc machining pom parts - Import export

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Material: White POM Processing type: CNC Turning machined

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

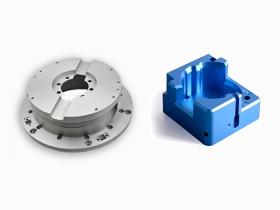

This is a plastic cavity for CNC milling.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The plastic material can be the POM/NYLON/PP/PVC.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning black POM part

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Material: ASTM, JIS, DIN, BS, iron, steel, aluminum, manganese, carbon steel, stainless steel, etc. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions. ISO 9001:2015 & IATF 16949 accredited

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

nozzle part manufactured by CNC turning and milling on sliding head multi-axis CNC lathe material: brass size: diameter 30 mm, length 47.80 mm tolerance: DIN 2768-F top inner thread M 12x1.0 bottom external thread M 25x1 With sliding head multi-axis CNC lathes, we are capable of producing complex parts requiring turning, milling, drilling, tapping, broaching etc in one setup.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, etc. Surface treatment: Customer's Request, color anodizing Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP) Tolerance: Customer's Drawing Request, ±0.01-0.02

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

CTT is an international high-tech enterprise that integrates research and development, production, and sales of precision parts.The company's business encompasses auto parts, new energy products, medical equipment, power equipment, industrial parts, and other fields. In the field of sheet metal processing for medical devices, CTT is renowned for its high-precision laser cutting technology, CNC bending equipment, professional die drawing technology, and high-quality welding equipment.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

The mechanical iris is a camera aperture component inspired by the human eye's iris, designed to precisely control the amount of light transmitted. It consists of a series of staggered curved thin metal blades, and by adjusting the relative motion of these blades—either closing or expanding—the size of the central circular opening is modified, thereby precisely controlling the light transmission. This design is not only applied in the apertures of photographic equipment but also in a variety of window systems for automatic light regulation and in security systems that control light to protect sensitive equipment.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

CTT has demonstrated outstanding expertise and an innovative spirit in the field of new energy vehicle chassis manufacturing. The company employs a range of advanced machining processes, from precision cutting and CNC bending to automated welding technology. Each step ensures high-performance and high-quality products. Additionally, professional surface treatment and precision machining of the chassis components further enhance the durability and reliability of the products. In terms of quality control, CTT has implemented a rigorous inspection process to ensure that every product meets high standards. After accurate assembly and comprehensive performance testing, CTT provides strong support for the chassis manufacturing of new energy vehicles, winning widespread trust and recognition from customers.

Request for a quoteResults for

Cnc machining pom parts - Import exportNumber of results

13 ProductsCountries

Company type