- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning drum

Results for

Cleaning drum - Import export

PARSMEGA MAKINA

Turkey

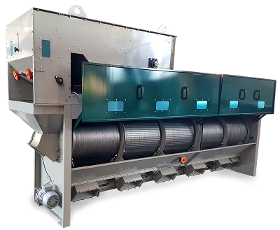

Our drum type Pre-Cleaning Machines; It is produced in the capacity range of 20 - 100 tons per hour. With the ÇSI Pre-Cleaning Machine, all unwanted foreign substances (garbage, dust, straw, etc.) in all kinds of grains (wheat, barley, corn, canola, soybean, etc.) are perfectly separated at a level that does not require cleaning again. Thanks to its airlock and cyclone as well as its excellent filter, it leaves absolutely no waste in the environment. Our sieves, which are designed according to the structure of all kinds of products, are easily mounted on the machine. Thanks to the brushes placed on the sieves, the sieves constantly clean themselves as the machine operates. With its high suction power dust collection and filter system, it does not leave any dust waste in the environment. The Pre-Cleaning Machine, designed by ÇSI engineers using advanced technology, will provide the cleaning you need for many years.

Request for a quote

ROBINSON CO.

Turkey

It’s for selecting the materials adjusts or aches and non- needed, which are in the wheat. The rollers pushed on the It separates impurities such as seed, barley, rye, lentil, cracked wheat, long grain and absut in wheat, corn, lentil, rice, and similar grains and is used to separate the broken pieces. Foreign substances and broken grain in the product entering the rotating drum enter into specially made drum pockets with a rotating steel body by centrifugal force. When the rotating drum reaches a certain point, foreign substances and broken grains in the pockets fall into a special adjustable channel in the drum. While the cleaned grain comes out of the drum, foreign substances and broken grains falling into the channel are ejected by a spiral placed in the channel. During operation, the dry grain in the drum makes powder. This dust is extracted by low pressure air. In the food industry; In flour and semolina factories, Bulgur factories, In lentil cleaning facilities,

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B2 Battery drum pump is suitable for low-viscosity, aqueous to slightly viscous media, such as plasticisers, cold cleaners and lubricants. The set is suitable for dispensing small containers such as canisters or hobbocks. The pump is flexible at all times and thus conserves important resources. The set is supplied without battery and charger. * Replaceable, powerful rechargeable battery with Li-Ion * Battery life 35 min at maximum speed * 1 battery charge empties approx. 12 x 200 litre containers Features & benefits * BLDC motor with high efficiency up to 70% * Infinitely variable * Long battery life * Automatic switch-off in case of overload * Sophisticated quick-release fastener * The max. flow rate is a value determined by means of a test bench and measured with water at a medium temperature of approx. 20° C. The measurement is taken at the pump's discharge nozzle, without hose, nozzle or flow meter.

Request for a quote

FLUX-GERÄTE GMBH

Germany

With the Drum pump F/FP 425 there is less than 0.05 l residual amount left in a 200 l drum, so maximum 0.02 %. The pump has an integrated backflow valve that is easy to close before taking the pump out of the container. Thus the backflow of the medium in the pump is prevented. This makes optimum use of especially expensive media possible and saves additional cleaning and disposal costs when handling problematic media. The pump is available in stainless steel, polypropylene and hastelloy C. In stainless steel and hastelloy C the pump F/FP 425 can also be used in hazardous areas. Benefits: - Optimal residual emptying with e.g. less than 0.05 l residual amount left in 200 l drum - Two adjusting levers to easily close the backflow stop - No tilting to totally empty the drum - Reduction of cleaning and waste disposal costs - No loss of medium when taking the pump from drum to drum - Optimal use of fluids

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Pump Set is suitable for thin, flammable and inflammable liquids and hydrocarbons. Perfectly suited for withdrawing or transferring explosive media and solvents. * Optionally available with Ex - plug * Pump tube equipped with Lutz original hand wheel * Suitable for Drum emptying alternative fuels, oils, flammable liquids Features & Advantages * Optionally with electric or compressed air drive * No lubricants and therefore no contamination of the pumped medium by lubricants * Optimised Drum emptying with a remaining quantity of approx. 0.1 litres * No leakage if the pumping station is tilted or moved * Maximum product utilization with reduced drum cleaning and disposal rates * Approved according to ATEX directive 2014/34/EU, category 1/2

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX® Brake Cleaner is a highly effective cleaning agent for drum and disc brakes, brake linings and pads, clutch linings and pressure plates, as well as all parts in and around the motor vehicle which are contaminated with oil, grease, etc. Due to the high proportion of active ingredients, an intensive and fast-acting cleaning is achieved. No residues remain. It is not corrosive and generally does not attack rubber and plastics. However, due to the variety of plastics on the market, a compatibility test is recommended.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Pump Set is suitable for thin-bodied, flammable and highly inflammable hydrocarbons. Perfectly suited for the withdrawal or decanting of solvents. * Media examples: Ethanol, petrol, butanol, isopropanol, kerosene, methanol and petroleum.etc. * Pump tube equipped with Lutz original hand wheel * Suitable for Drum emptying alternative fuels, oils, flammable liquids Features & Advantages * Optionally with electric or compressed air drive * No lubricants and therefore no contamination of the pumped medium by lubricants * Optimised Drum emptying with a remaining quantity of approx. 0.1 litres * No leakage if the pumping station is tilted or moved * Maximum product utilization with reduced drum cleaning and disposal rates * Approved according to ATEX directive 2014/34/EU, category 1/2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Pump Set is suitable for thin, flammable and highly inflammable liquids and hydrocarbons. Perfectly suited for withdrawing or transferring explosive media and solvents. * Optionally available with Ex - plug * Pump tube equipped with Lutz original hand wheel * Suitable for Drum emptying alternative fuels, oils, flammable liquids Features & Advantages * Optionally with electric or compressed air drive * No lubricants and therefore no contamination of the pumped medium by lubricants * Optimised Drum emptying with a remaining quantity of approx. 0.1 litres * No leakage if the pumping station is tilted or moved * Maximum product utilization with reduced drum cleaning and disposal rates * Approved according to ATEX directive 2014/34/EU, category 1/2

Request for a quote

CTI PROCESS APS

Denmark

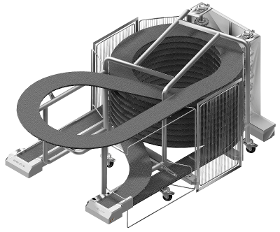

A superior proofing solution. Handcrafted in Denmark. Zero Compromises. This space-saving spiral proofer delivers continuous uniform heat distribution and high production capacities of baked products. Each product piece is kept at uniform temperature regardless of its position on the conveyor belt. Temperature, humidity and conveyor speed are independently adjustable and PLC controlled. Our Edge Drive proofer has no internal drum drive, making cleaning simple and efficient. Insulated cabinet and stainless steel construction are built to Danish standards.

Request for a quote

CTI PROCESS APS

Denmark

A superior cooling solution. Handcrafted in Denmark. Zero Compromises. This space-saving ambient spiral delivers continuous uniform cooling and high production capacities of meat, poultry, seafood, vegetable and baked products. Each product piece is cooled uniformly regardless of its position on the conveyor belt. Temperature, air circulation and conveyor speed are independently adjustable and PLC controlled. Our Edge Drive Ambient Spiral has no internal drum drive, making cleaning simple and efficient. Insulated cabinet and stainless steel construction are built to Danish standards.

Request for a quote

CTI PROCESS APS

Denmark

A superior freezing solution. Handcrafted in Denmark. Zero Compromises. This space-saving spiral freezer delivers continuous uniform freezing and high production capacities of meat, poultry, seafood, vegetable and baked products. Each product piece is frozen uniformly regardless of its position on the conveyor belt. Temperature, air circulation and conveyor speed are independently adjustable and PLC controlled. Our Edge Drive freezer has no internal drum drive, making cleaning simple and efficient. Insulated cabinet and stainless steel construction are built to Danish standards.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The OBC-355 universal grain cleaning separator is the most multifunctional drum-type machine for cleaning grain in the world. The number of operating options for the OBC-355 grain cleaning separator exceeds 50. The multifunctionality of the OBC-355 drum cleaner allows it to be used to separate and calibrate a wide range of products (for example: a mixture of any grain, grain with very high clogging, corn with very high humidity, cotton fibers and seeds, glass balls, etc.). The OBC-355 grain cleaning machine can be used both for high-quality calibration and for preliminary cleaning with large volumes of processing. Multifunctionality is achieved due to the innovative design of OBC-355, consisting of a large number of flap valves, screws and 2 main parts: an aspiration unit that removes light impurities depending on the air flow controlled by the regulation of aspiration; cleaning and calibration unit with a rotating drum that removes small and large impurities

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Our systems dose in parallel into stationary and mobile tanks. The systems work with mass flow meters or measuring cells and scales. Dosing cluster ■ Dosing of large components for mixtures up to 12 tonnes ■ Stationary or mobile tanks ■ Flow rate: 30 - 250 litres/min ■ Parallel dosing with several scales or with mass flow meters ■ Barcode-supported dosing ■ Unattended operation ■ Integrated suction on the dosing cluster ■ Different weighing ranges ■ Explosion protection according to Atex The advantages are obvious: simply add the remaining large components to your premixes - in a single additional work step - and of course with barcode support and fully automatically. With our modern storage systems, you can remove large components from several drums simultaneously at any time. Labour and cleaning-intensive pumping from drums into mixing containers is a thing of the past.

Request for a quote

GAICTECH

Spain

The Pin-Bone Remover Machine is an innovative solution designed to efficiently remove bones from various types of fish and the shell from crustaceans such as shrimps, prawns, or king prawns, whether raw or cooked. This versatility ensures the production of an excellent product for a wide range of applications. The machine offers optional features like constant and controlled feeding through a helicoid mounted on the reception hopper and customizable diameters of the holes in the drum (between 1.5 and 8 mm), depending on the desired product outcome. Constructed from durable stainless steel AISI 304, it meets the highest standards of hygiene and longevity. In the canning industry, particularly for tuna, it's used to separate bones from flakes generated during the cleaning process, with a perforated drum that's easy to assemble or disassemble. The diameter of the holes can be adjusted to balance production and flake quality, with smaller diameters

Request for a quote

MAXRAY KIMYA SANAYI VE TICARET LIMITED SIRKETI

Turkey

It cleans calipers and linings, discs, drums, brake center cylinder, clamps, springs and clutch parts in the brake system and increases the holding feature. Thanks to its special formula, it provides cleaning of grease, tar and other oils that have formed layers by combining with dust without much effort. You can also use the package by turning it 180 ° upside down.

Request for a quote

BEITO

Belgium

K2 BRAKE CLEANER is a super-efficient cleaner for brake system components. It cleans and degreases disc and drum brakes, clutches, metal surfaces, parts and tools. It removes dirt, oil, brake fluid and grease without leaving any residue. Contains no harmful chlorinated solvents. Reduces whistling and noise. It has a pleasant lemon fragrance. USAGE: 1. Spray soiled parts from approx. 20 cm. 2. Allow to evaporate completely or wipe with a clean, dry cloth. Repeat this procedure several times if necessary. Warning: Do not use on polycarbonate plastics, do not wash rubber parts. It doesn’t contain any ingredients generally described as harmful to health.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEMIA INDUSTRIE

France

Installed at the inletof the line for granular products such as peas/flageolets, it removes small waste, sticky waste as well as large waste. Machine mainly consisting of a drum whose perforations in the final section are adapted to the product being treated. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Exit of the products to be treated under the 3rd section of the drum. Recovery and evacuation of waste thanks to a belt conveyor placed inside the drum (except for small waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Depods hand harvested pods. Machine formed primarily from two concentric drums comprising 12 bats on the inner drum and 16 counter bats on the outer drum. Extraction of the pods and light waste from the flow of products thanks to an inclined belt under the double drum. Easy to clean thanks to its three removable screens.

Request for a quote

NOVA KIMYA

Turkey

Usage Areas and Features: It is a concentrated product. It is a product suitable for use in all areas where heavy oils and dirt are present. It is suitable for use in areas including ovens, oven pans, burnt oils, tar, soot residues, chimney smoke, hoods, automobile factories, mechanical services. It penetrates, loosens and dissolves burnt and oil residues very strongly. It is ensured that all residues flow from the surface by rinsing. It does not leave bad odor and residue, it is not flammable. It is applied with hot and cold water. Form of Use and Quantity: Applied by brushing, spraying or dipping methods. It is diluted with water at a ratio of 1/50 for applications by a high pressure sprayer. It is diluted 1/10 with water for applications by brush and dipping method. 10 minutes after application. wait and rinse with plenty of water. On cold surfaces, apply with a brush or sprayer, wait, rinse or wipe with a wet cloth.

Request for a quote

BELIMED LIFE SCIENCE AG

Switzerland

Designed as a cleaning system for containers, drums, pallets and other large-sized vessels, the PH 880.2 is part of an extensive model range (PH 820.2, PH 840.2 and PH 860.2). The tailored operational sequences for professional pharmaceutical processes maximises efficient throughput. Based on standardised technical design and years of Belimed Life Science’s experience in automatic cleaning, the PH washer range covers a wide range of cleaning requirements and features harmonised construction characteristics throughout the various models. The PH 880.2 combines highest possible component standardisation with the necessary design flexibility to achieve best possible adaptation of the machine to the requirements of the production process.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

BALABAN 54 MAKINA DIS.TIC.LTD.STI

Turkey

Capacity: 1000 to10000 Lt / h Drum Rotation: 7250 r/m Drum Drainage Volume: 12 Lt. Drum Material: DIN 1.4462 Dublex Working Tempreture: +4-60 C Input Pressure: 0-2 Bar Cream Output Pressure: 1-2 Bar Milk Output Pressure: 1-4 Bar Working Frequency: 50 hz Engine Power: 15 kw Recommended Ampere: 12 amp Recommended Working Heat: 45-55 °C Water Pump's Engine Power: 0,75 Kw Total Weight: 1150 kg Cream separator has automatic cleaning rotary. Rotary drum is adjusted on control panel and impurity is discharged. Rotary drum works using operation water. Drum has high mecanical durability and is made of Siemens Brand PLC Control Unit, Siemens Brand 6" colourful touch-operated control panel, Siemens brand 15 kw actuator, 650*400*1200mm insulated stainless electrical panel, Platform designed to assemble machine, electrical panel and hydrophore. 0,7 kw stainless, automatic hydrophore.

Request for a quote

MÜLLER GMBH

Germany

2.1 / 01 Lidded drum with stackable base Lidded drums with stackable base 2.1 / 02 Lidded drum with flat base and base ring 2.1/02 Lidded drum with flat base and base ring 2.1 / 03 Lidded drum with flat stackable base Lidded drums with flat stackable base 2.1 / 04 Lidded drum with torospherical base Lidded drums with torospherical base 2.1 / 05 Lidded drums with lateral base outlet Lidded drums with lateral base outlet 2.1 / 06 Ultra Clean Drum Ultra Clean Drum

Request for a quote

MÜLLER GMBH

Germany

Step 1: Filling Insert plunger Fill product into drum Step 2: Storage Storage Transportation to filling line Step 3: Preperation Special emptying lid placed over drum Step 4: Emptying Drum emptying through the product piping to the filling line Step 5: Ready for a new load The drum is clean The drum can be filled again

Request for a quote

MÜLLER GMBH

Germany

Step 1: Filling Insert plunger Fill product into drum Step 2: Storage Storage Transportation to filling line Step 3: Preperation Use pallet truck to move drum into drum-emptying stand Lower the cover with the handwheel Step 4: Emptying Drum emptying through the product piping to the filling line Step 5: Ready for a new load The drum is 100 % empty It is easy to clean The drum can then be filled again

Request for a quote

MÜLLER GMBH

Germany

Too much product loss when emptying drums, complicated cleaning of pump and container systems, high handling costs and problems with the stringent hygiene requirements: a daily headache for companies working with viscous products. Efficient drum-emptying systems by Müller have long set the standard in a diversity of applications in many industries. Your benefits: GMP compliant system needs little space and is safe and simple to operate different seal qualities available Drum-emptying system For creams, ointments, adhesives, pastes, paints 100 % emptying 30 - 1000 liters

Request for a quoteResults for

Cleaning drum - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Pumps (4)

- Agriculture - Machines & Equipment (2)

- Conveyor systems (2)

- Refrigerated transport equipment (2)

- Rolling machines (2)

- Bakery ovens (1)

- Chemical catalysts (1)

- Chemicals - Basic Products & Derivatives (1)

- Diesel engines (1)

- Flour milling - machinery and equipment (1)

- Food Processing (1)

- Oils, cooking - machinery and equipment (1)

- Portable electrical pumps (1)

- Steam polishers (1)

- Sterilisation and disinfection - medical equipment (1)

- Vehicle maintenance products (1)

- Weighing and dosing equipment (1)