- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping devices

Results for

Clamping devices - Import export

COPIER MACHINERY

Netherlands

Copier Machinery manufactures compact, versatile, and easy to install modular concept clamping devices. They clamp the workpiece concentric with high precision and high repeatability. The clamping process is faster and with constant pressure with Copier’s clamping devices. Special jaw sets are used depending on the workpiece diameter, size, and shape to assure proper clamping of the workpiece. The clamping devices distinguish itself in outstanding reliability and are designed for the roughest production procedures. Copier’s clamping devices are easy to integrate into manufacturing lines and are available in manual, pneumatic, and hydraulic versions. Diameters vary from 5 mm up to 410 mm (0.2" – 16").

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

Our company boasts a robust development team proficient in constructing automatic clamping devices tailored for mechanical processing. This innovative process enables us to achieve higher repetition rates and accuracy on the piece, ultimately resulting in superior quality products. Additionally, by utilizing these automatic clamping devices, we can offer our clients competitive pricing without compromising on quality.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Flexible for small lot sizes Fast jaw change with quick change design and high repeatability – that is what makes the B-Top jaw chuck product line so flexible. Particularly for small lot sizes. Thus in most cases machining the chuck jaw to size is unnecessary. Conveniently adapted to your requirement Also the insert bushing system is configured for small lot sizes and maximum flexibility. It enables clamping devices to be conveniently adapted to your requirement: Closed with ejector, spray nozzles, or with variable end-stop. Just the way you need it. And the innovative lubricating system ensures improved clamping force behavior of the wedge bar principle.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Lower mass The »mini« series really shines with a mass reduced by as much as 30 %, and a chuck diameter that is reduced by 1/3. This means reduced energy consumption and better tool accessibility. Naturally, add on clamping elements can also be used with the TOPlus mini chuck. To maintain the minimal interference contour, the TOPlus mini chuck has its own adaptation devices with a smaller bolt hole circle. Reduced interference contour Thanks to the reduced interference contour, it is easier to choose the tool that you need. Now it can also be shorter and more stable – on the main and sub spindles. Particularly in the case of limited installation space and in series operation, the TOPlus mini chuck is ideal: Lower energy consumption, dynamic spindle acceleration, and shorter cycle times reduce the costs per workpiece. Minimalism that pays off!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Reliable and long life SPANNTOP nova – this development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. The components are optimized for balance quality, and have an extended guide length. The clamping length of the workpieces is also significantly greater. This chuck is designed for maximum RPM and holding power at ideal concentricity. It is extremely rigid, precise, and has an extremely long life. Convenient change The position-oriented base end-stop of the »combi pull-back« and »combi deadlength« variants can be conveniently changed from the outside via three clamping screws countersunk in the chuck, and for standard chucks, provides excellent accuracy for face location combined with through-bore capacity. Chuck SPANNTOP nova: reliable and solid. The product is the result of more than 30 years of experience!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Concentric and eccentric complete machining Concentric and eccentric complete machining in a single clamping set-up? That’s right! With our compact chuck you can turn an eccentric position on the workpiece – in a single set-up without having to re-chuck it! Thus you save time and money. Automatic change-over Change-over from concentric to eccentric takes just a few seconds – it is automatic and convenient due to the setting tool in the turret and the c-axis of the machine spindle. Minimum set-up times and no machine changes whatsoever. And first and foremost: You can use your normal clamping cylinder.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Flexibility thanks the modular system I.D., O.D. or jaw clamping – it‘s easy with the B-Top3 modular system. Everything fits together. With MANDO Adapt segmented mandrel, you can change to perfect I.D. clamping in less than 2 minutes. The SPANNTOP adaptation is the right partner if you have reached your holding power and accuracy limits for O.D. clamping. And all without removing the chuck!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Unequalled rigidity Up to 25 % more clamping force and higher output – with the same clamping cylinder that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. The clamping head rests with full-surface contact in the TOPlus chuck body – even with large workpiece tolerances. Insensitive to dirt In addition this geometry ensures that TOPlus is significantly less sensitive to contamination than previous chuck/clamping head solutions, and with a concentric precision of approx. 0.015 mm [for chuck size 65]! Thus TOPlus is even better suited for raw material, cast and forged parts, as well as fi ne-particle non-ferrous metals such as brass. Therefore, all-round optimized values make the chuck an ideal partner for modern manufacturing strategies and state-of-the-art machine tools. TOPlus – simply revolutionary!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum precision in a mini format The TOPlus premium chuck is ideal for high-precision clamping of delicate and thin-walled parts, as well as solid and massive parts. In combination with premium clamping heads and when clamping against the end-stop, you benefit from incredible run-out accuracy of ≤ 5 μm. That makes the standard TOPlus premium chuck a better and less expensive alternative to hydro-expansion and diaphragm clamping devices. In addition to high precision, the large opening stroke also facilitates automated loading of the machine – even if the robot is somewhat inaccurate. By the way, slight contact with the workpiece during loading has no negative effect on the TOPlus premium. Despite its high precision it remains »robust« and your process remains stable. The most accurate of all HAINBUCH chucks!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

NORELEM FRANCE

France

Body tempered. Ball hardened (50 - 55 HRC). Note: Self-aligning pads serve as stops, supports and thrust pads in fixture construction. They can also be installed in existing clamping devices, e.g. arness clamps. Ball is secured against rotation. Drawing reference: Form C: male thread, smooth flattened ball Form F: male thread, serrated flattened ball

Request for a quoteSTÄHLE GMBH

Germany

Actuator for precise operation of accelerator pedal in vehicles. External set-point of the scaled pedal position via analog voltage. Fast and simple installation with universal and patented clamping device fixed to the seat rail of the driver seat. Temperature resistant actuator in fail-safe design with de-coupling of the drive by an electro magnetic clutch. Un-powered the pedal can be applied by the human driver. Other interfaces like field bus can be offered. This actuator is also used for vehicle dynamic and unmanned driving tests with the automatzed driving system SPFhybrid !

PRESSTA EISELE GMBH

Germany

Drive 7,5 kW, S 6, 400 V, 50 Hz, R.P.M. of sawblade infinitely adjustable (2.000 – 3.500 R.P.M.) Sawblade Ø 500mm, smaller blades on request Cutting range max. 215 x 120mm (height x width) Hydro pneumatic saw blade feed, Speed infinitely adjustable, linearly under the tabletop from rear to front Material fence on the table for the cutting angle Feed length limited via 4 end switch horizontal profile clamping device on the feed and discharge side Cycle spray mist device Pusher Profile feed from right to left with ball screw and servo motor Feed length from 10 to 2500 mm Feed speed max. 250 mm / sec. Repeatability +/- 0.1 mm iincl. horizontal pneumatic clamping device Reversing possible, max. Stroke length 7,300 mm Siemens S7-300 with touch screen 10“

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMSYS GMBH

Germany

SAMSYS offers Spindle Liner for draw tube diameters from 38mm to 100mm. The length of the reduction tube depends on the length of the draw tube, as well as the clamping device and the type of clamping cylinder. The reduction tube consists of a precision steel tube as support tube (1). In order to ensure optimum guidance, the rear (2) and the front (3) guide are adapted to the lathe. Mounting as well as dismounting can be done in a very short time with a few simple steps, as the reduction tube is only attached to the clamping cylinder with two screws. The POM bushings (4) can be flexibly adapted to the material diameter. Since you do not need to store a reduction tube for every diameter, you save valuable storage space. A Water pan extension (5) is also available as an option for safe covering and splash protection.

Request for a quote

FRANKE GMBH

Germany

Cassette with star grip - standard Cassette with star grip or clamping lever for locking at any position on the guide track. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. Please consult us for further information. Cassette with clamp lever Cassettes with clamping levers allow the cassettes to be locked in any position along the guideway. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. We would be happy to advise you on application and design.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Vibrating table can be used both for compression and also for loosening bulk material. Typical applications are compacting of e.g. concrete mixes or the unstick/knock out of molds. There are two different approaches: The load to be vibrated, is set loosly on the table or firmly clamped to the vibrating device. Advantages & benefits variable, can be used for different tasks easy to regulate with magnetic vibrator Construction Compact design, with attached magnetic vibrator/s or unbalanced motors below the tabletop. Selection The sizing depends on: bulk material, such as bulk density, particle shape and internal friction the properties of the container, such as height, stiffness and sidewall Key figures length: up to 4,000 mm width: up to 2,000 mm payloads: up to 3,000 kg drive: magnetic vibrator, unbalanced motor, exciter

Request for a quote

KULLEN-KOTI GMBH

Germany

Should you have not been able to find the suitable lath brush for your application although our standard range is most versatile, we trust that our special types might come up perfectly to your requirement. They also offer best quality to meet your most particular wishes. You can choose for instance between frame shape, angled or arched shape; special fixing devices such as round drill holes or slots; threaded, grooved or clamped holding devices. In case of large-scale requirement we also provide especially moulded plastic or metal cores made either by injection moulding or diecasting. Please see the index card "brush assembly" for the core material. Furthermore we have wood, steel, stainless steel, light or heavy metal in our assortment.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

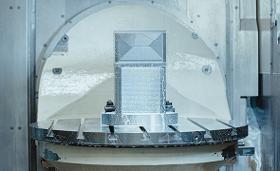

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles Clamping device with 6 or 8 workpieces Processing the ends and connections on MFZ Processing of deep hole drilling 4-6 spindling on SAMAG shaft drilling machines

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of mobile equipment for cutting and welding metal. Our products are designed to offer the highest precision and flexibility wherever they are needed. From pipe cutting devices to hand-held flame cutting machines to portable oxy-fuel technology - we have the solution for your requirements. RSV pipe cutting devices Our mobile pipe cutting devices enable the simultaneous cutting and beveling of steel pipes. Thanks to the quick-clamping device, they can be fixed in any position, offering maximum flexibility and efficiency. The cutting torch can be rotated by 45°, adjusted in height and sideways and can optionally be motorized. Hand-held flame cutting machines ZINSER's mobile hand-held flame cutting machines are designed for daily use. They offer precise and reliable cuts with maximum user-friendliness. ZINSER oxy-fuel technology ZINSER has been involved in the economical use of acetylene and other gases for over 100 years.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

In order to get started with low pressure molding technology, for prototyping new projects and producing small series, Labline offers a selection of small devices tailored to the requirements of low pressure molding technology. The basis here is the hand-held casting gun with a 0.2l tank for filling the casting materials in granulate form. In order to achieve process stability and reproducibility even with this manual processing, a timer can be connected. Two different clamping devices are available for convenient handling of sample and pre-series tools. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesive, hot melt adhesives, special machines for adhesive processing, hot melt packaging, machine for gluing, machines for gluing, hot melts, gluing machines, hot melt coating, gluing machines for labels, laboratory coating machines, systems for adhesive technology]

Request for a quote

AHP PLASTIK MAKINA

Turkey

Computercontrolled (CNC) test bar milling machine with installed machining programs and special clamping devices will prepare samples for tensile tests and other specific shaped sample required tests The CNC milling machine is a tabletop unit with protective doors. Preconfigured machining programs for all common sample shapes The allround enclosure ensures safety at the workstation The milling machine is optionally fitted with pneumatic clamping devices Test samples with a maximum length of 250 mm, a maximum thickness of 50 mm can be milled as standard. Optionally thickness of 100 mm is available. Delivered with workbench Test samples milled in accordance with standard dimensions Machined areas cooling with compressed air Highquality unit components guarantee long service time

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBE320-523 3D has been developed for cutting 3D-Printing Plates in different sizes up to 500 x 300 mm. Highest precision ensures optimal cutting results and guarantees, that neither the printplate nor the printed parts get damaged. The result is, that the height of the supporting structure of the printed parts can be reduced. The individual fabrication of the bolted plates provides high flexibility for sawing 3D-Printing Plates in different sizes and shapes. The Stop-System with alignment on the printplate simplifies the set-up mode and reduces sources of errors. The fixture ismoveable, which ensures an easy loading and handling. To adapt the sawing system to the process in an optimal way, BEHRINGER offers various options such as machine cover with suction device, spray mist system and individual clamping devices.

Request for a quoteResults for

Clamping devices - Import exportNumber of results

91 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (36)

- Lighting, street, industrial and commercial (4)

- Sawing machine tools (4)

- Wires and cables, steel (4)

- Mechanical engineering - custom work (3)

- Poles, metal (3)

- Industrial cabling (2)

- Metals - Machines & Equipment (2)

- Additives, cement and mortar (1)

- Bearings - ball, needle and roller (1)

- Clamp collars, plastic (1)

- Cleaning and maintenance products, industrial (1)

- Control panels - electric (1)

- Custom packaging (1)

- Custom packaging - companies (1)

- Cutting - machine tools (1)

- Electronic components (1)

- Finished Metal Products (1)

- Forming, rubber - machinery (1)

- Handling - Machines & Equipment (1)