- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change machines

Results for

Change machines - Import export

RULOMATIK

Turkey

It sells automatic towel for reliable cleaning in cars and it works 24/7 long-term. It works with coins and gives the product to the user from the product reservoir of consistently the same quality car drying cloth. • LINK and Analogue/Pulse servo drives models • High-response frequency of 1 kHz • Auto-tuning for easy and quick start-up • Vibration suppression • Positioning, speed or torque control • Separate power and control power supply • Fast and accurate positioning • Incremental and absolute encoder

Request for a quote

RULOMATIK

Turkey

It sells automatic towel for reliable cleaning in cars and it works 24/7 long-term. It works with coins and gives the product to the user from the product reservoir of consistently the same quality car drying cloth. • LINK and Analogue/Pulse servo drives models • High-response frequency of 1 kHz • Auto-tuning for easy and quick start-up • Vibration suppression • Positioning, speed or torque control • Separate power and control power supply • Fast and accurate positioning • Incremental and absolute encoder

Request for a quote

RULOMATIK

Turkey

It sells automatic towel for reliable cleaning in cars and it works 24/7 long-term. The machines accepting various forms of payment, including coins, credit cards, and mobile payments. Gives the product to the user from the product reservoir of consistently the same quality car drying cloth. • LINK and Analogue/Pulse servo drives models • High-response frequency of 1 kHz • Auto-tuning for easy and quick start-up • Vibration suppression • Positioning, speed or torque control • Separate power and control power supply • Fast and accurate positioning • Incremental and absolute encoder

Request for a quote

RULOMATIK

Turkey

It sells automatic towel for reliable cleaning in cars and it works 24/7 long-term. It works with coins and gives the product to the user from the product reservoir of consistently the same quality car drying cloth. • LINK and Analogue/Pulse servo drives models • High-response frequency of 1 kHz • Auto-tuning for easy and quick start-up • Vibration suppression • Positioning, speed or torque control • Separate power and control power supply • Fast and accurate positioning • Incremental and absolute encoder

Request for a quote

SHENZHEN TENKING TECHNOLOGY CO., LTD.

China

Therapy myopia glasses use for children and teenagers improve myopia eyesight. 3 times therapy can higher eyesight 100-150 degree, effect-ion rate is 90%-95%. After 90 times therapy eyesight normally could higher 200-300 degree. Just need keep use 1 time per day only.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS.PSC offers maximum stability and rigidity coupled with maximum flexibility. Significantly reduce your setup and changeover times while maintaining high mold flexibility. he EWS.PSC program includes a wide range of standard tools with PSC shank for milling spindles as well as tool systems with PSC spindle for lathes. Furthermore, tool holders with plate seat are available. The interface allows you to reduce the time spent measuring, setting up and changing tools. In addition, improved machine utilization can be achieved.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal Machine flexo 500 scores with maximum versatility and flexibility even in its basic configuration. Whether frozen pizzas, biscuit boxes, fruit and vegetables, books, skis, laminates or various household goods, etc., you are instantly equipped for any kind of application with this machine – daily changing orders, for example. The flexo 500 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent film packaging machine flexo 700 scores similarly to the basic modell flexo 500 with maximum versatility and flexibility, but is designed for the packaging of large format products with a width of up to 680 mm. Whether shoe boxes, boards, shelves, ladders, ironing tables, large calendars, pots, tissue rolls, insulating mats, etc., you are instantly equipped for any kind of large format application with this machine – daily changing orders, for example. The flexo 700 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films, dimensions and products.

Request for a quote

FERPLAST SNC

Italy

FPXBAG-NEW is an innovative semiautomatic vertical packaging machine which combines different existing technologies with unique innovations. FPXBAG-NEW is an easy to use, economical and functional form-fill-seal machine which creates 3 hermetic sealing bags starting from a plain foil roll. Compared to the other vertical machines, FPXBAG-NEW has an innovative system of forming box which allows to get a fast format change. This systems reduces the machine shot-down and we gain in productivity. Moreover the two clamps of the horizontal sealing allow to keep the forming bag in position reducing the any break possibility. The key factor of the FPXBAG-NEW is the versatility of the machine which can seal any kind of film, this thanks to the incomparable sealing system. The machine is supplied with 1 forming tube type 200 (suitable for making bags with a width of 185 mm). On request it is possible to have forming tubes with different sizes, type 200 and type 250.

Request for a quote

FERPLAST SNC

Italy

Suitable for all types of neutral or printed film (preferably with antistatic treatment) or tubular polyethylene with thickness from 0.06 mm to 0.13 mm or tubular polypropylene with from 0.03 mm to 0.05 mm thick, and cartene normal or high density. Furthermore, with the FP BAG EVO it is also possible to use expanded polyethylene (FOAM) in tubular reel with a maximum thickness of 1.5 mm. It can use reels with a width of 80-300 or 100-500 mm without disassembly of parts or changing settings. The packaging machine automatically perform the forming of the bag with the upper opening. The filling of the bag and the subsequent closing can be done manually by an operator who starts the cycle of the machine through a button, or automatically by means of feeders, manipulators, weighers. The reel change takes a maximum of thirty seconds. The machine cycle time for the preparation of a bag 200 mm long is about four seconds.

Request for a quote

DAMS MACHINE

Turkey

Our machine is used in bagel, roll, sandwich and hamburger breads. Machine settings can be made on PLC and digital display. These settings are saved in the recipe and do not want to be re-adjusted in product change. Machine chassis is made of 304 Cr-Ni sheet metal. It has the feature of spraying the desired amount of water, eggs, slurry and molasses on top of the products in the flat tray or molded tray. At the same time, it can sprinkle the desired amount of granular materials such as sesame, bran, kernel, rye on the products on the flat tray or molded tray. It is simple to use and clean.

Request for a quote

SCHMALE GMBH & CO KG

Germany

The SVM1/1P is a high quality machine for attaching hinges and clasps with fastening prongs. The single hinges and single clasps are attached to your product (cases, caskets…) with this machine. Special features Changing the operating mode “Hinge fastening“ and“ Clasp fastening“ is very quick to carry out. Benefits / Characteristics can be used for various materials (all types of wood, certain tinplates and plastic) very low capital cost ideal for short runs precision attachment of the hinges and clasps consistent high quality ease of operation verschiedene Befestigungsarten möglich (Innen- und Außenanschlag, Flach- und Schiebedeckel) works with all Schmale hinge and clasp models with fastening prongs meets current machine regulations 2006/42/EU “CE“ only branded components used very maintenance friendly service and maintenance available Made in Germany Technical Data Dimensions / Hinge fastening mode: Length 500 mm Width 750 mm Height 1,180 mm Dimensions / Clasp fastening...

Request for a quote

FILLPACK GMBH & CO. KG

Germany

2 x 2 dosing pumps with motorised individual adjustment from 0 – 500 ml nearly maintenance-free machine with automatic central lubrication system Fully-automatic cleaning of filling machine (CIP/SIP) Quick and simplified format change (15 min.) Two filling machines enabling alternate operation/cleaning Heatable hopper (35°C – 95°C) Diversion and feeding of filled jars to the cooling zone Film applicator station Sealing station Multi-transport plate for all current jar diameters

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

At the present, toilet paper production has become an industry that requires high speed and efficiency. The 2 Channels Log Saw (Toilet Paper Cutting Machine) is a critical part of this process and is an industrial machine with advanced Technology that allows toilet paper rolls (logs) to be cut in standart sizes and with high precision. By making sharp cuts at high speed, this machine significantly increases both the efficiency of the toilet paper production process and product quality. Moreover, its rapid adaptation to ever-changing market demands makes this machine indispensable for toilet paper production facilities. The 2 Channels Log Saw Toilet Paper Cutting Machine is a high capacity industrial machine designed to cut long and continuous toilet paper rolls (logs) according to specified dimensions. The most important feature of this machine is its two-channel structure.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

USM 10 The skiving machine for the workshop. For skiving hoses up to 2” on the inside and the outside. 0.37 kW drive. USM 10 ecoline variant in 1-phase design, all others in 3-phase design. USM 10 S The new skiving machine: The lowest change-over times due to preset tool. Higher productivity due to low change-over times and user friendly operation for optimum results.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

We reserve the right to make technical changes without notice. Options are machine parts that can only be ordered while buying the machine. Press designed specifically for the production of automotive hoses. A good example for such a tailor-made solution is the HMC 1-25 and the HMC 1-30 with patented C-shaped crimping tool designed for radial insertion of complex hose lines. This special press is an ergonomically designed, low-noise machine that requires no lubrication. It has been specifically devised for the production of hoses for the automotive industry, offering outstanding press forces and precision. With PFC and other optional features, you can adjust the press force to process materials that are easily damaged, producing strong and lasting connections without any need for gluing, screwing or welding.

Request for a quote

PLASTIC UNION

Belgium

the price per packaged unit decreases significantly a lighter packaging is per definition a more ecological packaging a lighter packaging enables you to save a lot on packaging taxes for a same reel weight you will have much more meters, and thus much less reel changes on the machine. Less reel changes means less machine stops and a better productivity of the packaging line last but not least is economy and ecology going hand in hand ! If your company is working on decreasing their ecological footstep, then with these products you will undoubtly find an answer to this question!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

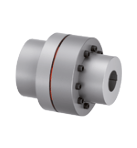

RINGFEDER POWER TRANSMISSION GMBH

Germany

Multi-part design, elastic ring can be replaced without having to axially move the machine The coupling TSCHAN ® TNM G is a torsionally elastic and puncture-proof claw coupling. It balances out angular, radial, and axial shaft misalignments within defined limits. The coupling transfers the torque via pressure loadable, elastic buffers or Perbunan (Pb) which are joined together as an intermediate ring. The elastic intermediate ring can cushion impacts and torsional vibrations; it is oil-tight and electrically conductive. A coupling half is divided in two and allows through this a simple separation of the coupled machine. With the claw ring pulled back it is possible to check the rotational direction of the drive. It is also possible to lift out radially a coupling half with accompanying aggregate. The elastic intermediate ring can be changed without axially shifting the machine. The coupling is usable in every sense of rotation and installation position. TSCHAN ® TNM G Multi-part...

Request for a quote

MÜLLER HYDRAULIK GMBH

Germany

This high-pressure unit proves that high performance and modern design do not have to be expensive. The highest efficiency in the compact class is safeguarded by the new concept with three times the filter surface. Thanks to its perfected measurements, the combiloop CL1 can be fitted under many bar feeders. Also as a mobile unit, it is ideal for changing locations on various machines, e.g. for short runs.

Request for a quote

STARRAG GMBH

Germany

The Bumotec s191V is the combination of proven Swiss made mechanics and stateoftheart CNC control and drive technology. With the CNC Bumotec s191V mill / turn center, precise and complex components can be produced via 5axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel. Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warmup cycles when starting or after machining interruptions. Features Linear driven motors and directdriven rotation axis High speed spindles (maximum 40,000 rpm) Smart combination of turning and 5axis machining High thermal stability Automatic tool changer for 90 HSK40 tools

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION This machine is ideal for the single corner welding of PVC profiles between 30°- 180°. Enable the welding of all angles between 30°-180°infinitely adjustable All parameters such as melting and welding time, welding pressure are set independently Automatically start and finish the welding cycle Adjusting the heat between 0-300°C by means of the electronic thermostat Smooth welding operations for long profiles by means of rotating support arms Maintenance friendly, for example cleaning of the heater plate and changing of the Teflon is very easy by means of quick change system Practical adjustment of standardl (2 mm) or seamless (0.2 mm) welding options manually Standard equipped with height adjustable profile support arms on both side Clamping the profiles separately via foot pedal Saving of time by means of practical mold change feature Portable machine stand OPTIONAL ACCESSORIES Machine according to the profile height of 165 mm

Request for a quote

NOVA KIMYA

Turkey

Usage Areas and Features: Provides powerful and effective cleaning of cylinders and screws of injection and extrusion machines. Cleans hot runner systems. It is also suitable for protective cleaning during machine shutdowns. A very high cleaning result is achieved with a low dosage. By saving time and cost, problem-free color and raw material conversion is achieved. It minimizes the number of wastage and faults. It minimizes the loss of expensive raw materials. Easy to transport, store and use. It is not necessary to mix, dry and change machine temperatures. It is not corrosive, caustic to the skin and not harmful to health. It is recommended by reputable machine manufacturers. Form of Use and Quantity: Check whether the machine temperatures are suitable for the ENJOYCLEAN type to be used. Remove the polymer to be cleaned completely from the machine and wipe the feeding unit. Use ENJOYCLEAN without mixing with other raw materials.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Pipe cleaning systems are designed according to the processing requirements. Here the machine line length changes equivalent to the throughfeed speed. An alkaline cleaning station that adjusts to the individual degree of soiling of the pipe surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line.

Request for a quote

KOMAX HOLDING AG

Switzerland

The Kappa 331 is a modular cut and strip machine with a rotating blade module. Round, multilayered cables – with and without shielding – are precisely stripped in multiple steps. The machine can be changed over quickly, making it ideal for flexible use. The Kappa 331 automatic cut and strip machine is used for round conductors with a cross section of 0.22 to 35 mm² (AWG23 – AWG2) and for specific applications up to 50 mm². It performs full and partial pull-off operations on individual layers and strips the outer jackets from jacketed cables with outside diameters of up to 16 mm that are with or without shielding. The high efficiency results from the flexible configuration possibilities and the short conversion times. The Kappa 331 is ideal for work environments with highly diverse products made in large and small batches. Powerful belt or roller drives transmit forces in an optimum way for the widest various of jackets.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

- Modular design: common dosing systems can be used - Diving nozzle movement / dosing volume settings: Freely programmable, adjustable suction and dosing time, adjustable drip retraction - Easy and quick cleaning, manually – CIP - Easy and quick format change - Small machine footprint

OPTIMA PHARMA GMBH

Germany

1-lane supply Simple operation Intermittent operation Vials, injection and infusion bottles Magazine change without stopping the machine Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

Our vertical grinding centre RP 8 is the optimal machine for the complete machining of highly complex workpieces in one clamping. The RP design impresses with the following unique features: —5-sided complete machining —Highest machining and measuring accuracies —Stable cast iron construction —Hydrostatic bearings in the X, Y and C axes —Wear-free direct drives in the X, Y and C axes —Outstanding long-term accuracy and durability —Table diameter 800 mm —Max. 2,000 kg continuous table load —Excellent damping properties —Up to 2 grinding spindles on grinding head —Different tool changing systems available —All machining operations of the Ri grinding centres —Turning and milling operations —Horizontal machining —Guide path grinding —3-axis coordinate machining —Flat grinding in pendulum motion —Machining of special materials such as special types of glass or ceramics — Surface grinding in pendulum motion

Request for a quoteResults for

Change machines - Import exportNumber of results

45 ProductsCompany type

Category

- Brick-making - machinery and equipment (5)

- Change machines (5)

- Packing and packaging - machinery and equipment (4)

- Cosmetics (3)

- Machine tools, metal machining - parts and accessories (3)

- Milling - machine tools (2)

- Adjustment - machine tools (2)

- Cement-making - machinery and equipment (2)

- Concrete blocks (2)

- Sealing and wrapping - machinery and equipment (2)

- Machine tools - metal machining (1)

- Agglomeration and emulsification machines for the food processing industry (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Bars - non-ferrous metal (1)

- Bending machine tools (1)

- Brakes, servo-brakes and accessories (1)

- Hydraulic equipment (1)

- Import-export - agents (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Napkins, paper (1)