- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramic plates

Results for

Ceramic plates - Import export

CROSEAGIFTS LIMITED

China

Nordic Style Marble Gold Inlay Porcelain Dessert Steak Salad Ceramic Plates Tableware

Request for a quote

ART WOW

United Kingdom

Prince - ceramic dinner plate designed by Dan Avenell. These beautiful, unique, hand printed, ceramic dinner plates come in either 6", 8’’ or 10’’. Our 6" makes a beautiful trinket dish or saucer. Our 8" and 10" together the two sizes compliment each other as a side and main plate. All plates make stunning wall art.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera uses its deep ceramics expertise and process capabilities to manufacture ceramics with precisely controlled porosity. Porous ceramics are often used for chemical filtration and fluid separation. The range of Innovacera porous ceramics is made from aluminum oxide and silicon carbide. The strong, uniform porous ceramic has 40-50% open porosity with a tortuous pore structure and is available in pore sizes ranging from 1 to 100 microns. Three Main Application of Porous Ceramic: Vacuum Chuck, like scribing machine vacuum chuck, silicon wafer vacuum chuck. Adsorption platform. Suspension platform. Especially, they are widely used for the semiconductor industry, like LED wafer processing. The micro-porous ceramic working disk is a special tool for adsorption and bearing in various semiconductor wafer production processes, and is applied to processes such as thinning, dicing, cleaning, and handling.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia ceramic disc plates are characterized by high toughness, high bending strength, high hardness and high wear resistance.Zirconia ceramics have a dimensional hardness of 11.5GPa, a density of 6.0g/cm3 and a compressive strength of 2100MPa. Zirconia ceramics are widely used as ductile ceramics with fracture toughness up to 8.0 mpAM1/2. Advantages: smooth surface (easy to clean), good toughness, impact resistance, high hardness, wear resistance, low thermal conductivity (heat insulation), generally no insulation and high temperature resistance Applications: machinery, optical fiber, cutting tools, medical, food, chemical, aerospace Ceramic material composition: - - 95%--99.99% Alumina (Al2O3) - - Silicon Carbide · Silicon Nitride - - TTZ: Magnesia partially stabilized Zirconia (ZrO2) - - YTZP: Yttria partially stabilized Zirconia (ZrO2) - - ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hot pressed aluminum nitride (AlN) is used in applications requiring high electrical resistivity in additional to exceptional thermal conductivity. The applications for hot pressed AlN typically involve rigorous or abrasive environments and high-temperature thermal cycling.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

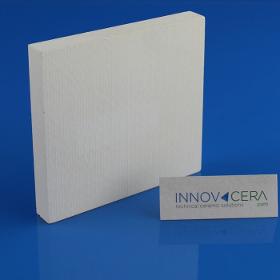

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o396%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Features: 1.High reliablility and sfety; 2.High density and mechanical properties 3.High electrical and thermal loading perormances 4.Low dilelectic loss and other characteristics

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

stainless steel*excellent stability*optimum height for use with Usbeckl aboratory Burners*space saving delivery and storage due to dismountable feet*Added value: Plate holder offers protective mat function

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

thickness 3,8 mm*chamfered edges*usable above open burner flame

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® copper and nickel are temperatureresistant connecting cables for internal wiring of electric household appliances such as hotplates, glass ceramic plates, grill appliances or storage heaters. In industrial applications CSN® Cables are preferably used for the wiring of heating elements, heating cartridges, tubular heaters, panel heaters, and quartz radiators. We manufacture these singlecore cables in cross sections up to 6 mm². Owing to their high temperature resistance up to 250 °C in the case of glass silk insulation and 600 °C in the case of mineral fibre insulation, these connecting cables meet the most demanding requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by the chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface on which the vapor is deposited.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

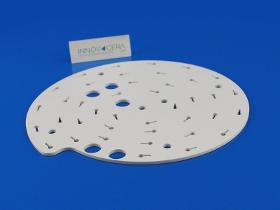

Innovacera supply the Porous ceramic plate/disc for Vacuum Chuck, which is mainly used to support and chuck the semiconductor wafer when grinding and dicing. It is applied in the process of thinning, dicing, clearance, transportation, and so on. Only one size in stock (Dia200*T3mm, 15um), custom size is available. Main Application field: — New and refurbished, porous ceramic chucks for Disco, ADT, K & S, Applied materials TSK, OKAMOTO, Micro Automation, Load Point, etc. dicing saws and grinders. — 6″, 8,” 12″ are regular sizes, And pore size include 15um, 30um, 50um, 100um. Materials are alumina (Color: white, light brown, dark brown, blue-gray) — Custom size (like square, oval shape, or irregular shapes) is available for us. Characteristics include: High flatness and parallelism Compact and uniform microstructure with high strength Good permeability and uniform adsorption affinity Long lifetime Dressing easily.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as aluminum oxide (Al2O3), is the most mature and commonly used technical ceramics. With excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina content ranging from 80% to more than 99% according to different application. It's widely used in automotive, petro-chemical, fluid contro, material transfer, industry, electrical and electronic, semiconductor,etc... - High Temperature Ability - Abrasion Resistant - Wear Resistance - Chemical Resistance - Electrical Insulator - Corrosion resistant - High compressive strength - High mechanical Strength - Resists strong acid and alkali attack at high temperatures - Excellent electrical insulation properties - Decent thermal conductivity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic plate is composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements * High Temperature Electrical Insulators * Extreme temperature measurement components * Ceramic Laser components * High voltage electrical insulators

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss PBN Plate Applications: For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

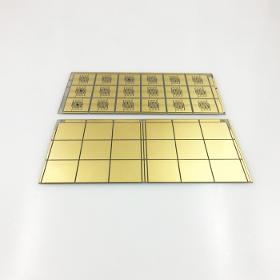

DPC Ceramic Substrate Advantages: > In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. > The crystal performance of the metal is good; > The flatness is good; > The line is not easy to fall off; > The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera supply the Alumina Porous ceramic disc for Vacuum Chuck which is mainly used to support and chuck the semiconductor wafer when grinding and dicing. It is applied in the process of thinning, dicing, clearance, transportation, and so on. Main Application field: — New and refurbished alumina porous ceramic chucks for Disco, ADT, K & S, Applied materials TSK, OKAMOTO, Micro Automation, Load Point, etc dicing saws and grinders. — 6″, 8,” 12″ are regular sizes, And pore size include 15 um, 30 um, 50 um, 100 um. Materials are alumina (Color: white, light brown, dark brown, blue-gray) — Custom size (like square, oval shape, or irregular shapes) is available for us. Characteristics include: High flatness and parallelism Compact and uniform microstructure with high strength Good permeability and uniform adsorption affinity Long life time Dressing easily.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Black High Purity Aluminum Nitride Ceramic Plate Hot pressed aluminum nitride (AlN) is used in applications requiring high electrical resistivity in additional to exceptional thermal conductivity. The applications for hot pressed AlN typically involve rigorous or abrasive environments and high-temperature thermal cycling.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater Chip for Automobile / Oxygen Sensor

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater for Automobile / Oxygen Sensor

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater for Automobile / Oxygen Senser

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quoteResults for

Ceramic plates - Import exportNumber of results

44 ProductsCompany type

Category

- Ceramics (32)

- Ceramics, industrial (22)

- Ceramics, refractory (5)

- Heating, industrial - installations and equipment (3)

- Ceramic, crockery (2)

- Ceramics, handicraft (2)

- Hotels, bars, cafés and restaurants - machinery and equipment (2)

- Laboratory equipment and instruments (2)

- Cables - accessories (1)

- Furniture for kitchens (1)

- Household appliances, electrical - import-export (1)