- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- centring device

Results for

Centring device - Import export

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

ADS-TEC Industrial IT offers two router/firewall series for network security in industrial environments. These are the IRF1000 and the IRF3000 series. These firewalls are an all-in-one solutions in terms of security. Several functionalities are offered in one product. The firewalls are convincing as a remote maintenance centre, router or edge device, which controlls networked machines and systems without cascading and securing them locally. Thanks to the integrated Docker technology, the IRF series can process data independently, making them the ideal platform for versatile applications in the Industrial Internet of Things. Depending on the model, the networks range from 400 Mbit/s to 8 x 1000 Mbit/s.

Request for a quote

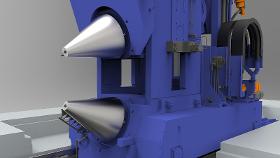

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Centring device - Import exportNumber of results

3 ProductsCountries

Company type