- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cam mechanisms

Results for

Cam mechanisms - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

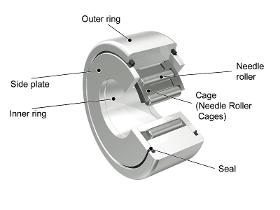

IKO Roller Followers are bearings with needle rollers in the thick outer ring that are designed for outer ring rotation. There are separable and nonseparable models, double row cylindrical, and other models available. Roller Followers are widely used as follower bearings for various cam mechanisms and as guide rollers for linear motion in conveying equipment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Cam Followers are bearings with a stud that incorporates needle rollers in a thick walled outer ring. These bearings are designed for outer ring rotation and provide superior rotational performance, a low coefficient of friction and high load capacity. In order to effectively increase the loading zone, this bearing is designed to have a smaller radial clearance than general needle roller bearings, so the shock load is lessened and stable long life can be obtained. Since the studs already have threads or steps, they are easy to mount. Cam followers are follower bearings for cam mechanisms and linear motion and have high rigidity and high accuracy. They are used mostly for machine tools, industrial robots, electronic devices, and OA equipment. Stainless steel cam followers have superior corrosion resistance and are suitable for use in cleanrooms and environments where oil cannot be used or where water might splash.

Request for a quote

SYNERLINK

France

The CANFL filler is flexible, precise and perfectly adapted to the constraints of filling with complex products. Its unmatched robustness has proved itself over several years with major players in the canning industry. We are using volumetric filling with pistons which are mechanically controlled by synchronised camshaft The CANFL filler is characterised by the high-level regularity and precision that are guaranteed by the mechanically-controlled cams (repetitive motion).

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quoteResults for

Cam mechanisms - Import exportNumber of results

7 ProductsCountries

Company type