- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- calculating machines

Results for

Calculating machines - Import export

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

COMERC SP. Z O.O.

Poland

We design, manufacture, build, train and service The pellet production lines designed and installed by our company offer capacities ranging from 2 t/h to 20 t/h. The capacity achieved naturally depends on the number and power of the machines and equipment comprising the production line. Pellet production lines – the offer: •design (technical conceptual design, formal arrangements, technical documentation, manuals, cost calculation), •supply (machines, devices, measuring and control apparatus, control cabinets, and all installation materials), •installation (machines, devices, control cabinets, measurement, control and feed wiring, post-installation testing, acceptance measurements), •software (controllers, operator panels, visualisation and control systems), •commissioning (machines, devices, control cabinets, control and power installations), •training process operators, programmers and IT technicians and technical human resources, •service within the warranty period and beyon

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Shaft Couplings RfN 5071 Standard series – this range is the most popular, being used in most applications. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need considerable effort with mounting and removal. The Shrink Disc connection has none of these disadvantages and is better than any of...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Stainless steel series – for applications where corrosion resistance and high transmissible torque is required. This new design of Shrink Disc is made from stainless steel forged rings and uses high strength stainless steel screws. These units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Standard series – this range is the most popular, being used in most applications. This new design of Shrink Disc is made from high alloy forged rings and is practically indestructible. Replacing the smaller 4071 design, these units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INO MACHINERY

Turkey

CNC profile machining center with economical design cabin moving on X-Y-Z axes. It can work on aluminum and PVC profiles. Specially designed for door and window profiles. It works on profiles with a high-speed spindle moving on a steel body equipped with a CNC controller unit and servo motors. The reference point at the beginning and end of the machine is lifted manually and determines the zero point of the profiles. Profile clamping pneumatic vices are placed on linear guides in 4 units as standard equipment. It works with Uni_Link, customized software for door&window manufacturing, and the clamp positions are displayed on Uni_Link’s own interface. Thanks to the Uni_Link program, Dxf drawings of door and window profiles are exported to the machine HMI. The size of the door profile to be processed is entered, hinge type, lock type is selected, and the machine performs parametric calculations on the profile perfectly.

Request for a quote

BAF CONTROL AKUSTIK GURULTU DENETIMI LTD. STI.

Turkey

BAF IPT-25 series products are produced from special PU rubber. These bearings are used as an antivibration product for mechanical machines for different types of machines. Every machine would be calculated and evaluated to select wright product with wright dimensions and wright application designs. The height of antivibration pad material is 25mm. Deflection dimensions and natural frequence values may be change according to the model of pad.

Request for a quote

ELMOR

Switzerland

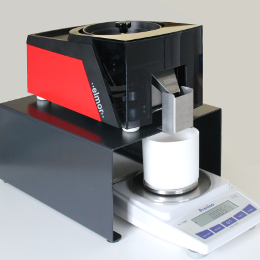

With seed tests the 1000 kernel weight is an important quality criterion, which must be determined with high accuracy. Counting and dosage of mechanical and electronic small articles as SMD’s are made increasingly also over the determination of the 1000 grain weight. By means of an additional software module, an electronic balance and a special frame, our precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Technical data Scales are available with a resolution of 1 mg, 10 mg or 100 mg. The data of the elmor C3 seed counter and the scale are sent to the control computer via two RS232 ports or – on request – with two USB cables.

Request for a quote

ELMOR

Switzerland

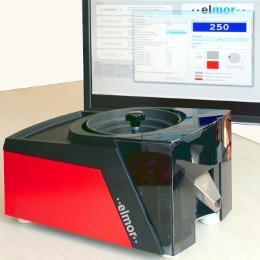

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quote

TECHNOWAGY LTD

Ukraine

Equipment provided electronic weighing with automatic calibration. To install the empty packages to the filling of the pipe and its attachment clamping device requires human intervention. Filling occurs in stages: first a powerful stream, then thinner for correct dosage. Packing in valve bags over after filling them in strict accordance with the specified parameters. Dosing mechanism overlaps pipe valve, clamp device automatically resets to the receiving transport packaging tape. Filling machine provides highly accurate formation of the mass dose valve bags. The weight of the dose, dosing regimens, and other variables are set by the operator from the keyboard of the control. Easy to use and intuitive management interface, ease of installation and configuration. Filling machine calculates the total amount of product that passes through it and may make that information on RS 485 to a computer or programmable logic controller.

Request for a quote

HAVER NIAGARA GMBH

Germany

http://www.niaflow.com NIAflow Basic: The Basis of Professional Process Simulation The intuitively operated program NIAflow Basic is a free simulation software for a smooth process functioning in processing technology. The basic version enables the presentation of simple dry, mechanical processes focused on crushing and screening. By using NIAflow, up to 10 machines can be represented in a printable flow chart and the mass flow can be calculated. On the basis of these calculations, machine-specific labels are displayed with the current data. Process optimization, pre-calculation of product or even the engineering of complete plants are thus supported. Besides the basic machines for processing mineral raw materials, the entire HAVER & BOECKER equipment portfolio is already deposited in the object list. It also comprises a classifying screen design with up to 4 decks. NIAflow Basic can be used to become acquainted with the program for free, for a process simulation of smaller...

Request for a quoteResults for

Calculating machines - Import exportNumber of results

12 ProductsCompany type

Category

- Additives, cement and mortar (1)

- Adjustment - machine tools (1)

- Anti-vibration supports (1)

- Automation - systems and equipment (1)

- Laser - cutting and welding machines (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Weight and mass - measurement and regulation instruments (1)