- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bulk transport

Results for

Bulk transport - Import export

GT SEMI TRAILERS

Turkey

CEMENT TRAILER CEMENT TRAILER also known as silo trailer which is used for carrying different bulk items like cement, flour, wheat, lime and else. This kind of Bulk Cement Trailer has different usage opportunities like tipping silo trailer, or euro type trailer. As GT Semi trailer we offer a wide range of Cement Trailer with different specification and different capacities such as cement trailers; v type cement trailers, stainless cement trailers, aluminum cement trailer.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Safe storage and transport: Siempelkamp is your container manufacturer for heat-generating and non-heat-generating radioactive materials Wide range of designs for all classes We produce a variety of containers for handling radioactive materials of all classifications. The choice of materials ranges from the use of different casting qualities to granulated concrete and steel. The range of services is completed by the authorization to carry out type tests. For more than 30 prototype types, the required certificates of qualification for the transport and storage of the casks have already been successfully completed in our manufacturing facilities. CASTOR ® casks bodies CASTOR ® casks are used as transport and interim storage containers for fuel elements and high-level radioactive waste.

Request for a quote

PETROGAZ

Turkey

CEMENT TRAILER also known as silo trailer which is used for carrying different bulk items like cement, flour, wheat, lime and else. This kind of Bulk Cement Trailer has different usage opportunities like tipping silo trailer, or euro type trailer. As Petrogaz and Dogan Yildiz we offer a wide range of Cement Trailer with different specification and different capacities such as cement trailers; v type cement trailers, stainless cement trailers, aluminum cement trailer.

BULK & TIPPER MAGAZINE

United Kingdom

For just £81.00 / year, you can subscribe to Bulk & TIpper and receive the magazine by post four times a year.

Request for a quote

BULK & TIPPER MAGAZINE

United Kingdom

For just £51.00 / year, you can subscribe to Bulk & TIpper and receive the magazine by post four times a year.

Request for a quote

BULK & TIPPER MAGAZINE

United Kingdom

For just £32.00 / year, you can subscribe to Bulk & TIpper and receive the magazine by post four times a year.

Request for a quote

SAUCE MASTER LTD

United Kingdom

Thicker than most imports, perfect sweetness, not too hot, perfect as a dip, as a spread, and even a marinade. Serve with meat, vegetables, poultry and fish. No Allergens, no artificial sweetners, no colours. Real chillies, real flavours.

Request for a quote

BIGBAGSACK

Turkey

Bigbag type which assure that the products picked in their natural environment will keep their freshness and have a long shelf life. As the ventilated parts on the body permit constant air circulation the filled product does not rot and depreciate due to lack of air. Mostly used for Hazelnuts Agricultural products such as potatoes, onions and carrots Timber, wood and other similar forest products

Request for a quote

BIGBAGSACK

Turkey

All products of Antistatig bigbag in 4 groups are produced with certificates obtained from objective test houses recognized by our industry. FIBC – Type A FIBC – Type B FIBC – Type C FIBC – Type D

Request for a quote

BIGBAGSACK

Turkey

Cost-benefit wise 1 &2 Loop bigbags are the most advantageous bigbag types. While the simple construction facilitates the usage, various fabric widths permit a wide volume range. Its unique design provides the maximum loading capacity at a minimal cost and consequently assures advantages in freight cost as well. This type can be designed both for non-hazardous goods described in EN ISO 21898 and hazardous goods classified as UN. Depending on the handling process, the bigbag can be manufactured either with 1 or 2 lifting loops, with coated or uncoated fabric and with or without liner. The liners can be attached to the outer body in different ways depending on the requirements.

Request for a quote

BIGBAGSACK

Turkey

Q bags as known in the industry are bigbags which do not bulge on the sides and keep its geometrical shape when filled. This provides a series of advantages to the users. Thanks to the stable and non bulging structure, less space loss on storage Up to 20% extra volume during filling More product delivery in transport which results in proportional freight gain We propose different “baffle” options which provide maximum profitability depending on the application

Request for a quote

BIGBAGSACK

Turkey

National or international transportation of hazardous goods is regulated with UN Recommendations on the Transport of Dangerous Goods which aim to prevent possible accidents and consequent problems as well as to minimize the environmental effects. In order to assure that the UN classified goods are safely transported and stored, we subject our UN Bags to related tests and provide our customers with certificates given by independent international test houses. In respect to UN recommendations, we perform the following 6 tests in our inhouse test laboratory to verify the quality of the said bigbags: Top lift test Drop test Topple test Righting test Stacking test Tear test All approved bigbags have a valid UN certificate and the certificate info is marked visibly on each bigbag.

Request for a quote

BIGBAGSACK

Turkey

In 4 loop big bag production we have a wide range of products which can answer to all special requests of our customers. Our big bags keep various products produced in different industries from humidity, electrostatical hazards and external factors, elongate the shelf life and assure a safe storage and transportation with no loss of quality. While designing and manufacturing our big bags we prioritize safety as well as our customer’s demands and needs. We provide different design options for different industries. Standard big bag types are available for a loading capacity of 100 to 2500 kg and according the EN ISO 21898:2005 regulation can be manufactured as 5:1 (single use), 6:1 (multiple use) or UN (Recommendations on the Transport of Dangerous Goods) in conformity with the certificates issued by reputable international test houses.

Request for a quote

PLASTIC PALLETS UK / ASSOCIATED PALLETS LTD

United Kingdom

Plastic Pallets UK / Associated Pallets Ltd deliver throughout the UK, nationwide and throughout Europe. We can offer a very next day delivery throughout the UK and 90% of the time deliver AM.

Request for a quote

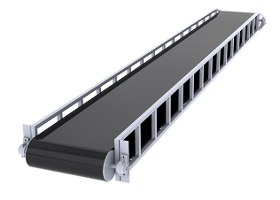

PARSMEGA MAKINA

Turkey

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

The screw elements can be mounted on a square shaft. You transport bulk materials into bins or silos via rotary movements.

Request for a quote

BÜRKLE GMBH

Germany

If bulk goods are transported over long distances (in trucks, railway goods wagons), separation may occur. Taking the sample just from the surface therefore leads to the wrong result. Representative samples from all layers of the silo can be taken with the SiloDrill. The SiloDrill fits through all standard openings with its diameter of 90 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

The Keiper UNITRANS conveyor belt series can be fitted with different sidewalls. Sidewalls are used as margin stops, usually together with cleats and entraining elements, in ascending and descending conveyor systems. The sidewalls prevent the products from falling off the sides of the belt. Inclined conveying: steep or angled conveying up to a slope of 80° in connection with cleats. Horizontal conveying: transporting bulk material and different-sized products. Conveyor belt sidewalls made of PVC, PU or special materials such as PU foam, polyolefin or polyester. With or without fabric interlayers. With or without foot. In the colors blue, white, green petrol, black or transparent. Depending on the design, in oil- and grease-resistant quality as well as FDA/EU approval. High abrasion and cutting resistance.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits energ

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. Advantages & benefits energy and space-saving vertical conveying that's gentle on the material low-maintenance continuous operation easy-to-clean, hygienic design natural cooling of the bulk solid during the conveying process thanks to long dwell times bulk solids cooled either directly by air or indirectly by water through the use of double bottom or laser-welded Thermplate® bottoms as the spirals

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Stonebox Hopper is a kind of storage container that is frequently used to store and move bulk materials including stones aggregates and other hard materials in the mining quarrying and construction industries. These hoppers are made especially to efficiently handle abrasive and heavy materials. The word Stonebox suggests that it is ideal for working with heavy rough stones or comparable materials. For the materials kept inside of them to cause impact and abrasion stonebox hoppers are usually built with a sturdy construction. Their role in overseeing the handling of bulk material storage and transportation in industrial processes is crucial. In real-world settings Stonebox Hoppers serve as a loading and storing unit for the orderly transfer of materials onto conveyors or downstream processing machinery. A consistent flow of materials is ensured onto the conveyor system for additional handling by the features built into these hoppers that make loading and unloading easier.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Stonebox Hopper is a kind of storage container that is frequently used to store and move bulk materials including stones aggregates and other hard materials in the mining quarrying and construction industries. These hoppers are made especially to efficiently handle abrasive and heavy materials. The word Stonebox suggests that it is ideal for working with heavy rough stones or comparable materials. For the materials kept inside of them to cause impact and abrasion stonebox hoppers are usually built with a sturdy construction. Their role in overseeing the handling of bulk material storage and transportation in industrial processes is crucial. In real-world settings Stonebox Hoppers serve as a loading and storing unit for the orderly transfer of materials onto conveyors or downstream processing machinery. A consistent flow of materials is ensured onto the conveyor system for additional handling by the features built into these hoppers that make loading and unloading easier.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Twin Bucket Chain Elevator? A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quote

STIF EASTERN EUROPE

Ukraine

The elevator bucket is designed for efficient transport of bulk grain and other materials in agricultural and industrial sectors. Manufactured using advanced French technology, the bucket ensures optimal performance by utilizing its full volume, increasing productivity. The innovative design reduces energy consumption by 15% and significantly lowers the metal capacity of the elevator system. Made from non-toxic, food-grade materials, the bucket prevents product damage and offers high wear resistance, making it an ideal solution for bulk product handling.

Request for a quoteResults for

Bulk transport - Import exportNumber of results

65 ProductsCountries

Company type

Category

- Bulk transporters (8)

- Conveyor belts (8)

- Goods handling systems, continuous (6)

- Concrete preparing - machinery and equipment (3)

- Newspapers and magazines (3)

- Pneumatic conveyor equipment (3)

- Road transport, tipper truck (3)

- Tanker transport - granular and dry bulk (2)

- Food canning and preserving - machinery and equipment (2)

- Transportation, bulk (1)

- Bulk materials for construction (1)

- Cheese (1)

- Container transport systems (1)

- Containers (1)

- Containers, metal (1)

- Crushing and grinding machinery (1)

- Food - import-export (1)

- Food Industry - Machines & Equipment (1)

- Goods transport (1)

- Handling - Machines & Equipment (1)