- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bars for turning

Results for

Bars for turning - Import export

MPRODUCT

Poland

complex geometry turning parts high accuracy

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

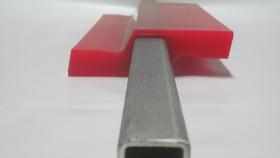

reasonably priced alternative for the cleaning of belt conveyors in the lower belt can be used twice by simply turning the bar round end to end PU turning bar also specifically for PVC and other types of plastic belts

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

610mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

ALUMAX

Greece

Alumax, also, offers final parts of a high quality level in competitive prices. We produce medium and even small batch size components, at short lead times, using our customer’s own drawings or samples. For this purpose, we have invested in modern machinery, such as CNC milling machines, sawing centers and punching & drilling center. Sawing Drilling Milling (from small parts up to 6m bars) Turning (up to a diameter 250mm and a length 800mm) Laser cutting Shearing Forming Punching Laser engraving The above processes, if appropriate, are followed by joining the parts together or with glass, plastic, etc., by welding, bolting, riveting or binding with adhesives.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

NC Turned Automotive Pins are a specialized type of pin that is used in the automotive industry. These pins are made using a CNC turning process and designed to meet specific requirements of the automotive industry. Automotive pins are used in various applications, such as engine and transmission mounts, suspension and steering components, or body panels. CNC Turned Automotive Pins are made from high-strength materials that can withstand rigorous automotive environments. The pins are precision-machined to tight tolerances, ensuring a perfect fit and function for the intended application. CNC Turned Automotive Pins come in a variety of sizes and designs to meet specific needs of the automotive industry. CNC turned automotive pins can be made from a variety of materials, each with its own set of benefits and drawbacks.If the material you required is not listed in the table, please contact us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turned Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating If you have any turned parts need to develop, welcome contact us to discuss your project. we will offer a competitive price to you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Small Turning Parts manufacuring more than 20years, we have old lathe turning machines, automatic turning machines, and High precision CNC turning machines, Turning & Milling Compound Machines. We can optimize the turning processes to make the machining cost to be lowest, accurate tolerance dimensions we use CNC turning machine, and low toleracne requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. As a professional small turning parts supplier from China,we can custom producing all kinds Carbon & Stainless steel turned parts,Copper & Brass turned parts,Aluminum Turned Parts & Machined parts, such as tube coupling, hose coupling, shaft, pipe joint parts, hose connectors & transition connectors, copper machined tube, flange,bushing, knighthead, pedestal, Piston Rod, insert long pin, Dowel Pin, Drive Pin & Rod,ball head bolt, long rod machined parts, long thread tube parts

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper

Request for a quote

ADIS FRANCE

France

drains (single-function suction cups) to remove air pockets from pressurised pipes KEY FEATURES - Built-in operation monitor - Ductile iron body EN-GJS 400 - Blue epoxy anti-corrosion coating - Minimum pressure: 0.1 bar - For brass 1/4 turn shut-off valve - Operating temperature: 1°C to 70°C - Flange drilling to EN1092-2 standard - A.C.S. certified product

Request for a quote

BDSENSORS GMBH

Germany

The differential pressure transmitter DPT 200 has been especially designed for the process industry and can be used for level measurement of closed, pressurized tanks, pump or filter controlling, etc. The possibility passes different pressure seals at the DPT 200 adding with different membrane materials to reach an optimal adaptation to the application. Features: — differential pressure von 1 mbar bis 20 bar — static pressure bis max. 400 bar — turn-down max. 100:1 — accuracy: 0.075 % FSO — HART®-communication — output signal: linear or square root extraction — aluminium housing Optional Features: — IS-version: Ex ia = intrinsically safe Version (group II) EX ia= intrinsically safe Version for firedamp mines (group I) Ex d = flameproof enclosure (group II) — LC-Display — stainless steeel housing

Request for a quote

BDSENSORS GMBH

Germany

The process pressure transmitter XMP i has been especially designed for the process industry and measures vacuum, gauge and absolute pressure ranges of gases, steam, fluids and dust up to 600 bar. Different process connections such as threads and flanges with an internal or flush welded diaphragm are available and can be combined with a cooling element for media temperatures up to 300°C. Features: — nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar — accuracy: 0.1 % FSO — turn-down 1:10 — two chamber aluminium die cast case or stainless field housing — internal or flush welded diaphragm — HART®-communication — explosion protection: intrinsic safety (ia) Optional Features: — explosion protection flameproof equipment (d) — SIL2 -version according to IEC 61508 / IEC 61511 — integrated display and operating module — special materials as Hastelloy® and Tantalum

Request for a quote

BDSENSORS GMBH

Germany

The precise pressure transmitter x\act i has been especially designed for food industry, pharmacy and biotechnology and measures vacuum, gauge and absolute pressure of gases, steams and fluids up to 40 bar. Several process connections e.g. thread or hygienic versions like Varivent, dairy pipe and Clamp with a flush welded diaphragm are available, which can be combined with a cooling element for media temperatures up to 300 °C. The robust stainless steel globe housing has a high ingress protection IP 67 and all characteristics for a residue-free and antibacterial cleaning. Features: — nominal pressure: 0 ... 400 mbar up to 0 ... 40 bar — accuracy: 0.1 % FSO — turn-down 1:10 — hygienic version — flush welded diaphragm — integrated display and operating module Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts — HART®-communication — Cooling element for media temperatures up to 200 °C

Request for a quote

BDSENSORS GMBH

Germany

The precise pressure transmitter x\act ci measures the pressure of gases, steam and fluids. The special-developed capacitive ceramic sensor for this transmitter, which can optionally be delivered in pure ceramic, has a high overpressure capability and excellent media stability. Several process connections e.g. inch thread or hygienic versions like Varivent, dairy pipe or Clamp are available. The robust stainless steel globe housing has a high ingress protection IP 67 and all characteristics for a residue-free and antibacterial cleaning. Features: — nominal pressure: 0 .. 160 mbar up to 0 .. 20 bar — accuracy: 0.1 % FSO — turn-down 1:5 — hygienic version — flush mounted, capacitive ceramic sensor — several process connections (inch thread, Clamp, ...) — with integrated display and operating module — diaphragm Al2O3 (99.9 %) Optional: — IS-Version Ex ia = intrinsically safe for gases and dusts — HART®-communication

Request for a quote

BDSENSORS GMBH

Germany

The process pressure transmitter XMP ci measures the pressure of gases, steam, dust and fluids. The special-developed capacitive ceramic sensor for this transmitter has a high overpressure capability and excellent media stability. Several process connections e.g. thread or flange are available. The transmitter is as a standard equipped with HART®-communication, the customer can choose between a two chamber aluminum die cast case or a stainless field housing. Features: — nominal pressure: 0 ... 160 mbar up to 0 ... 20 bar — accuracy: 0.1 % FSO — turn-down 1:5 — two chamber aluminium die cast case or stainless field housing — internal or flush mounted capacitive ceramic sensor — HART®-communication — explosion protection: intrinsic safety (ia) — diaphragm ceramics Al2O3 (99.9 %) Optional Features: — explosion protection flameproof equipment (d) — with integrated display and operating module

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MPRODUCT

Poland

max turning diameter Ø 300 mm max turning length 540 mm turning from bar max Ø 65 mm live tooling (milling, drilling) Y axis

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Liquid pressure type under the liquid pressures of 0.07–0.7 MPa (ca. 0.7 bar – 7 bar). Large turn-down ratio with minimal variation in spray angle. Uniform distribution suitable for multiple-nozzle arrangements. Large free passage diameter minimizes clogging. Standard spray angle of 55°, 70°, 95°, or 110°. Applications Cooling: Gas, steel plates, steel pieces, moldings, etc. [Steel making industry] Steel making process: Cooling continuous casted steel (slab, bloom, billet, beam blank, etc.) Rolling mill process: Cooling roll in heat treatment

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing semi-fine (and semi-coarse) atomization having a mean droplet diameter of 50μm or more. (*3) High spray impact with thin flat spray pattern and uniform distribution. Liquid pressure type under the liquid pressures of 0.2–0.5 MPa (ca. 2 bar – 5 bar). Large turn-down ratio with stable spray angle. Spray angle of 60° or 80° *1) Measured at compressed air pressure of 0.4 MPa (ca. 4 bar) and liquid pressure of 0.5 MPa (ca. 5 bar). *2) Free passage diameter of nozzle orifice. *3) Measured by Laser Doppler Method. Applications Cleaning: Printed circuit boards, liquid crystal, liquid crystal display, steel plates [Steel making industry] Surface finish process: Precision cleaning for steel surface treatment, Roll cleaning

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Classical machining, brass bar turning. Works well on fine carbon steels.

Request for a quoteResults for

Bars for turning - Import exportNumber of results

22 ProductsCompany type

Category

- Measurement and regulation equipment and instruments - pressure (6)

- Hydraulic tools (4)

- Turning - steels and metals (4)

- Nozzles - ferrous metal (2)

- Bending - steels and metals (1)

- Conveyor belts (1)

- Electric cars (1)

- Hydraulics systems (1)

- Lubricants, industrial (1)

- SMALL METAL PARTS (1)

- Turbine drilling services (1)