- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ball mills

Results for

Ball mills - Import export

EQUILAB

Spain

The EQM-402 Mixer Mill is a great ally when preparing samples for analysis, as it can mill, mix and homogenize quickly small volumes of sample. Especially designed for the final preparation of small quantities of hard, semi-hard and fragile samples - up to 50 ml -. This unit is able to prepare two samples simultaneously and to reduce them from an initial size of 0.8 a 1.5mm to a grain size of less than 10μ in a short time – 1 to 4 minutes -.

Request for a quote

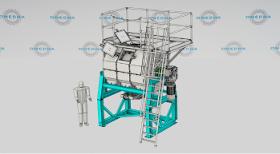

OMECHA UAB

Lithuania

Ball mills for crushing, and separating bulk materials. Batch milling controls the size of the material by adjusting the grinding time. The ball mill uses steel balls as grinding media. The ball mill can efficiently grind various materials into fine particles.

Request for a quote

TEKNIK MAKINA

Turkey

Ball Mill Dimensions: Labratuar φ90×150 Cm φ120×150 Cm φ120×300 Cm φ150×150 Cm φ150×300 Cm φ200×150 Cm φ200×300 Cm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Zirconia Ceramic Ball mill jar is one part of all kinds of grinding and mixing materials equipment. During the various types of ball mill jars, horizontal and planetary ball mill equipment are mostly used. Now let’s explore the differences between these two types of ball mill equipment so that you can select the right equipment for related application. Planetary sand mill equipment A planetary ball mill is an efficient ball mill equipment, its grinding principle is the grinding tank as a planet, through the interaction of the planet and the grinding ball, the grinding ball in the tank’s high-speed movement, and friction and collision with the sample or abrasive, to achieve the purpose of grinding. Planetary ball mill is suitable for the preparation of high-purity materials cell crushing and other fields, its biggest advantage is that the grinding efficiency is high, and the grinding particle size is adjustable.

Request for a quote

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

Dithiophosphate 25s or Hydrogen Phosphorodithioate is known to be a good flotation collector of copper, silver sulfide, zinc sulfide (activated), and lead ores. It can somewhat be dissolved in water. Also, it can be directly poured into ball mills and surge tanks.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For highest contact pressure and high circumferential speed, e.g. for rotary kilns, ball mills, rotary barrel mixers, ball mills, rope winches or friction presses also for guiding elements, slide bars, heavy transport chains and closed wire ropes Lubrication of rotating assemblies of convertors, cranes, crushers and dredges with spray or central lubricating systems Lubrication of heavily loaded gear couplings Advantages and benefits Most suitable for reliable supply of open gears, even at high circumferential speed Very efficient through EP additives in association with a specific combination of solid lubricants and adhesive additives Reliable protection of tooth flanks, even at high temperatures and with extended relubrication time Good pressure resistance of the lubricating film, excellent wear protection The film is not embrittling and aging. Without bitumen, solvent, does not contain heavy metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconium oxide jars 60 times the hardness of regular steel, highly wear-resistant and resistant to acid and solvents. The grinding jars are extensively applied to in the fields of Paint, Ink, Geology, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, Environmental Protection and so on. Each jar set includes grinding jar, jar lid, rubber sealing gasket and different sizes of mixed zirconium oxide grinding balls. Specification: .High cost-effective, low wear and long lifetime. .High specific gravity, high efficiency. .Highly wear resistant to acid and solvents. .Highly polished, smooth, easy to clean, low abrasion to the equipment. .High mechanical strength, good toughness, impact resistance, no broken beads. .Mainly used for lab planetary ball mill machines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ball Mill /Beads / Grinding Media is made of good material and used advanced technology, which is suitable for any kinds of mills such as sand mill, attrition-mill, vibratory mill, ball mill and so on. It is used to grind and disperse the material of painting, dye,ink, titanium, electronic battery material, rare-earth material, nonmetal ore, calcium, pesticide, food stuff and medicine etc..Because of its high density, toughness and hardness, zirconium grinding media’s efficiency is much better than traditional ones.The high wear-resistant zirconium grinding media can not only prevent materials from being contaminated, but also prevent chemical erosion that affects its working life Sizes Ømm of the Zirconia ball mill grinding media : - 0.2-3mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: - Ø0.5-3mm Grinding ball use in sand mill - Ø5-20mm Grinding ball use in mix mill and ball mill - OverØ20mm Grinding ball use in ball mill

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovcera offers yttrium stabilized zirconia YSZ ceramic beads as milling and grinding media, the standard size is from 0.05mm to 30mm, customized size is available, too. The zirconia ceramic beads can be high polished. Zirconia Ceramic jars are 60 times hardness than regular steel, it is widely used as planetary ball mill jar, laboratory grinding pot for milling finely soft or tough materials. Innovacera provides the standards zirconia mill jars including the jars, seal and lids, size is from 100ml to 3L, customized drawing design is accepted.

Request for a quote

OEN CHEMICALS GMBH

Austria

Chemical appearance Dithiophosphate 25s or Hydrogen Phosphorodithioate has an appearance of a deep brown or almost black liquid. Some may classify it as a vandyck brown oily liquid and it has a density of 1.17 – 1.20. It has a PH value of 10 – 13 and a mineral substances percentage of 46 – 49. Chemical application and strength Dithiophosphate 25s or Hydrogen Phosphorodithioate is known to be a good flotation collector of copper, silver sulfide, zinc sulfide (activated), and lead ores. It can somewhat be dissolved in water. Also, it can be directly poured into ball mills and surge tanks. Hydrogen Phosphorodithioate is used mainly in the separation flotation process of ores like lead and zinc. Because of its properties it should not be subjected to intense heat like fire or extreme sunlight. Proper packaging must be observed. It is weak in collecting sulfide minerals and pyrite when in alkaline medium. It also is selective in collecting ores.

Request for a quote

HEMOGUM

Serbia

Hemogum has its own recipes for mixtures with special requirements in the field of mining such as: mills with balls, shrink sleepers, rubber rotatory and stationary parts of horizontal and vertical pumps for handling of hydro mixtures with high resistance to abrasion. With Hemogum equipment we produce profiles of different diameters made from material of diverse quality, that attend requirements of the mining industry. In the construction area we produce spongy profiles, foils for acoustic and termo isolation, hydro isolation. Upon customer request foils can be made from different types of elastomer. Depending on the purpose, functions and customer request we make articles from: CR, NR, S8R, HR, BR, EPDM and NBR. In the field of energetics we produce electrical conductive mats, with width from 1 mm to 5mm. superficial resistence R<10 to 5<that is on 100000) W. Foils are NR. S8R quality orthe combination depending on its purposeand specific customers request. Foils may

Request for a quote

HAN SONG M&T

South Korea

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

Request for a quote

HAN SONG M&T

South Korea

·Copper, Graphite and non-ferrous metal ·Special coating to maximize the wear-resistance

Request for a quote

HAN SONG M&T

South Korea

[Product Description] D-PRO Series is used to cut copper, graphite, and ceramic parts, and is used for general face milling, profile & plunge milling. It is a diamond-coated End mill that is reinforced the wear resistance and enhanced the tool life. [Product Specification] Flat end mill : D0.5 ~ D12 + Various effective length / total length Ball end mill : D0.2 ~ D12 + Various effective length / total length C/R end mill : D2 ~ D12 + Various effective length / total length [Product Model] Flat : 2DRE, 2DPE, 4DPE Ball : 2DRB, 2DPB C/R : 2DRR, 4DRR [Product Use] * D pro series is pure diamond coated Endmill for cutting Graphite, Reinforced plastics, nonferrous metal etc. * Maximized thickness of coating for improvement of wear-resistance * Wide range of effective length and overall length for various work shape.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] S-PRO series is mainly used for cutting difficult-to-cut materials such as stainless, titanium, nickel and hastelloy in the aerospace field. A deep chip evacuation space of the S-PRO helps to cut difficult-to-cut materials, which facilitates chip evacuation and provides excellent surface finish. [Product Specification] Flat end mill : D1 ~ D20 Ball end mill : D3 ~ D20 C/R end mill : D1 ~ D20 [Product Model] Flat : 4SUE, 4SUEA Ball : 4SUB C/R : 4SUR, 4SURA [Product Use] * The cutting edge type of S pro series is unequal flute and it is suitable for cutting difficult to cut materials like alloly steels, stainless steels, Titianium, Inconel etc. * 4SURA, 4SUEA are specialized to cut Inconel. * Strong wear-resistance by adapting S-pro coating.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] D-PRO Series is used to cut copper, graphite, and ceramic parts, and is used for general face milling, profile & plunge milling. It is a diamond-coated End mill that is reinforced the wear resistance and enhanced the tool life. [Product Specification] Flat end mill : D0.5 ~ D12 + Various effective length / total length Ball end mill : D0.2 ~ D12 + Various effective length / total length C/R end mill : D2 ~ D12 + Various effective length / total length [Product Model] Flat : 2DRE, 2DPE, 4DPE Ball : 2DRB, 2DPB C/R : 2DRR, 4DRR [Product Use] * D pro series is pure diamond coated Endmill for cutting Graphite, Reinforced plastics, nonferrous metal etc. * Maximized thickness of coating for improvement of wear-resistance * Wide range of effective length and overall length for various work shape.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] D-PRO Series is used to cut copper, graphite, and ceramic parts, and is used for general face milling, profile & plunge milling. It is a diamond-coated End mill that is reinforced the wear resistance and enhanced the tool life. [Product Specification] Flat end mill : D0.5 ~ D12 + Various effective length / total length Ball end mill : D0.2 ~ D12 + Various effective length / total length C/R end mill : D2 ~ D12 + Various effective length / total length [Product Model] Flat : 2DRE, 2DPE, 4DPE Ball : 2DRB, 2DPB C/R : 2DRR, 4DRR [Product Use] * D pro series is pure diamond coated Endmill for cutting Graphite, Reinforced plastics, nonferrous metal etc. * Maximized thickness of coating for improvement of wear-resistance * Wide range of effective length and overall length for various work shape.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

Request for a quote

HAN SONG M&T

South Korea

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Chaoyang runxing heavy machinery Manufacturing Co.,ltd are engaging on manufacturing heavy machinery equipment and spare parts for almost 40 years, we could provide cement production line, rotary kiln, cement mill, ball mill, raw mill, slag mill, cement grinding equipment, preheating equipment, laterite nickel rotary kiln, oxidized pellet production line, air swept coal mill, mining mill, autogenous mill, semi-autogenous mill, rolling machine, vertical mill, crushing equipment, cooling machine, drying equipment, fluidized bed furnace, compound fertilizer equipment, blending machine, feeding machine. We passed the certification of ISO9000. Please contact us for more details. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Product Description OEM casting steel large diameter cement plant rotary kiln trunnion roller Trunnions are stout, steel wheels on which a rotary dryer drum rolls. Each must support anywhere from 10 to 20 tons. Trunnions must be smooth and round to reduce vibration, wear, and friction. It is important to match the tires to the trunnion wheels in both material composition. Key components of rotary dryers — trunnion wheels and shafts, bearings, drum tires, shell, head plates and seals — can wear and cause rotary dryer misalignment. Know what to look for and how to respond to what you see on your industrial rotary dryer. Rotary drum dryers are the workhorses of the industrial drying industry, but even workhorses can have maintenance problems. Fortunately, most problems occurring in industrial rotary dryers can be solved by making your drum rigid, round and aligned. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Product Description We can produce all kinds of cement rotary kiln accessories, including support roller,large diameter ring gear,kiln trye,bearing bush,shaft,kiln shell,girth gear,pinion gear,thrust roller assembly and so on. MaterialCarbon Steel , Alloy Steel SizeProcessing customized according to customer drawings Heat TreatmentQuenching and Tempering, Tempering, Normalization; Applicationmainly used in the transmission of Rotary Kiln Surface Finishaccording drawing TechnicalCasting, Forging, Welding; wechat:chaoyangrunxing zoeyguo369@gmail.com

Request for a quoteResults for

Ball mills - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Cutting - machine tools (15)

- Ceramics, industrial (4)

- Gears (2)

- Milling - machine tools (2)

- Mining and quarrying - machinery and equipment (2)

- Bearings, crankshaft (1)

- Ceramic and enamel kilns (1)

- Chemical catalysts (1)

- Cocoa and chocolate - machines and equipment (1)

- Flour milling - machinery and equipment (1)

- Import-export - chemicals and pharmaceuticals (1)

- Industrial design (1)

- Laboratory equipment and instruments (1)

- Lubricants, industrial (1)

- Rubber products (1)

- Silicones (1)