- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- back bars

Results for

Back bars - Import export

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

clamping force 7,5 kN, retention force 10 kN pendulum range ± 4 mm, hose at the back max. 250 bar, as per data sheet B1.733

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Trailer sway can be caused by crosswinds, poor trailer loading (load being too far back), or inadequate spring bar tension in the weight distribution system. The use of a weight-distributing hitch by itself may help limit trailer sway by evenly distributing the weight of the load, but it will do little to improve sway caused by crosswinds. To help control sway, a sway-control device is recommended for most standard weight distribution systems. Because sway control is so important, it is built into many systems. If you want to wait to add on a sway control device, you will likely be limited to a bar-style friction sway control. Trailer sway devices come in 2 basic types - those that reduce sway once it has begun and those that work to prevent sway altogether. Reduce Sway Sway control systems that reduce sway typically rely on friction to keep your trailer from shifting, preventing sway from increasing

Request for a quote

MACFAB SYSTEMS LTD

Ireland

The LH300 has a 20 Ton force. It can compact cardboard boxes, plastic film, FIBC bags, and other recyclable materials. It is an excellent choice for businesses to take control of their waste management. Makes a 300 kg bale of cardboard boxes. 4 rolls of strapping placed on a bar at the back of the baler to tie off bales. Alternatively, you can use steel wire to tie off bales. There are lifting pockets at the base of the baling press to easily move the baler into position with a fork truck.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc provides plug-and-play longitudinal seam welding machine for tubes, cylinders, vacuum components, water tanks, cones, flat sheets, etc. Advantages 1. Servo motor drive carriage and double linear guide way provides great precision of 0.05mm accuracy (0.002”). Motion speed reach to 2-16,000mm/min (1~640ipm). 2. Mandrel adopts with our special design copper backing-bar and copper clamper to dissipate heat quickly. 3.Strong machine structure provides large working capacity from thickness 0.1 to 10mm 4. Smart control box, you can get started quicker than you think with it. 5. High accuracy motion for laser welding standard. Welding process: All weldable metals by TIG, MIG, Plasma, Submerged arc welding and laser welding. *CE conformity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IBG HYDROTECH GMBH

Germany

With ABANO nozzle technology, approx. 15% less drive power is required. The power not required can additionally be used in the suction area. The cross-sectional area of the nozzle inserts is also reduced by approx. 15%, which creates an increased pressure size at the insert (low back pressure approx. 1 bar). Design details distinguish the new technology from the round jet nozzle technology currently available on the market and increase the cleaning power with lower energy and material consumption. Applicable up to DN 800!

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

Double Needle Lockstitch Machines DN 8442 AUT – Double needle lockstitch machine with drop and needle feed. This machine is driven by Ho Hsing direct drive AC servomotor. Machine is equipped with under bed thread trimmer, presser foot lift, automatic back tack and wiper (all electric). Machine has standard vertical axis hooks. DN 8442 LH-AUT – Same as DN 8442 AUT, but with large hooks DN 8420-AUT – Double needle lockstitch machine with drop and needle feed. This machine is driven by Ho Hsing direct drive AC servomotor. The machine is equipped with under bed thread trimmer, presser foot lift, manually disengageable needle bars, automatic back tack and wiper (all electric). Machine has standard vertical axis hooks. DN 8420 LH-AUT – Same as DN 8420 AUT, but with large hooks. Product DN 8442, DN 8442 LH, DN 8420, DN 8420 LH Table Top No Table Top, Table Top D 105x55x4 cm Stands No Stand, Stand C (China), Stand K (912 mm), Stand K short (667 mm), Stand Z Motor Set DOL (chinese...

Request for a quote

BORA YATIRIM CO. LTD.

Turkey

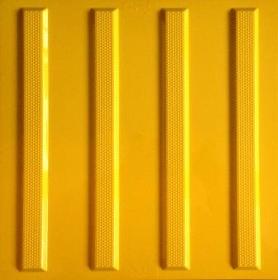

This product has guiding embossment tissue in bar shape (flat back) and tracks formed in parallel with the moving direction on its surface. The intended use of this element is to ensure safe access of the visually impaired to their destination. Our perceivable surface product with Guide Tracks is our most highly demanded product because of its function.

Request for a quote

SENOX ENDÜSTRIYEL MUTFAK SAN.TIC.LTD.ŞTI

Turkey

back bar two door from the factory

Request for a quote

IAE

United Kingdom

This crush is designed specifically for larger breeds and is an extremely heavy duty unit. YOKE DESCRIPTON Manual traditional lever operated yoke handle can be used on either side ; Spring loaded quick release adjustment gives 4 preset yoke widths from 165mm to 330mm ; Fully opening front and side gates form the front cage enabling greater access all around the animals head. BODY DESCRIPTION Fully welded tapered tread plate floor to help keep the animals feet inside the crush when the side doors are open ; Two full height side doors on each side (hinged from a middle pillar) allow full access with no obstructions to the animal’s flanks ; Rear gate included as standard ; Traditional backing up bar facility built into the side gates ; Pallet fork lifting points welded onto the top horizontal rails ; Approximate weight 515KG. PRODUCT DETAILS LENGTH - 3120 mm BASE LENGTH - 3000 mm WIDTH -1000 mm INTERNAL WIDTH - 900 mm HEIGHT - 1950 mm

Request for a quoteResults for

Back bars - Import exportNumber of results

11 ProductsCountries

Company type