- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- axis mill

Results for

Axis mill - Import export

PROMEX BG

Bulgaria

We also offer coatings in cooperation with our trusted suppliers: Hot galvanizing Powder coating Anodization Oxidation

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

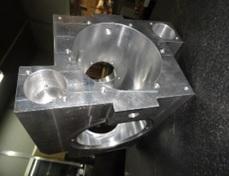

SCHMIDT Zerspanungstechnik uses state-of-the-art metal working machines to apply the finishing touches SCHMIDT Zerspanungstechnik's modern milling machines make it possible to custom-machine work pieces to extremely high precision during contract manufacturing work. Our machinery includes several universal machining centres and computer-controlled CNC milling machines; among them column, bed and gantry milling machines. 5-axis milling technology allows the machine to position and move the milling cutter at any angle to the workpiece which makes producing extremely complex 3D contours possible. In addition to this, our machines offers qualitative benefits in that almost all points to be machined can be reached without having to re-clamp the work piece. We also have fully controlled rotary index tables and indexing heads, and work with magnetic and vacuum clamping systems. We're able to machine work pieces of up to 10,000 mm in size.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik uses state-of-the-art metal working machines to apply the finishing touches SCHMIDT Zerspanungstechnik's modern milling machines make it possible to custom-machine work pieces to extremely high precision during contract manufacturing work. Our machinery includes several universal machining centres and computer-controlled CNC milling machines; among them column, bed and gantry milling machines. 5-axis milling technology allows the machine to position and move the milling cutter at any angle to the workpiece which makes producing extremely complex 3D contours possible. In addition to this, our machines offers qualitative benefits in that almost all points to be machined can be reached without having to re-clamp the work piece. We also have fully controlled rotary index tables and indexing heads, and work with magnetic and vacuum clamping systems. We're able to machine work pieces of up to 10,000 mm in size.

Request for a quote

STARRAG GMBH

Germany

The 5axis Mill / Turn center model s128 is a perfect combination of maximum performance and minimum footprint. On less than 2m², the s128 is a concentrate of high technology; Milling, Turning, Drilling, Engraving, Setting preparation and Diamond cutting processes are possible to produce parts as single unit or as serial manufacturing. The machining of miscellaneous parts from bar or blank and demanding perfect surface quality can be achieved with very short changeover time. Features Compact machine less than 2m² Flexible manufacturing solution Production from bar or blank 5Axis simultaneously

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material: aluminum alloy Surface treatment: machining surface Tolerence: IT7 Machining method: 5-axis cnc milling and drilling Usage: biochem element

Request for a quote

BULUT CNC MACHINING

Turkey

MATERIAL:DERLIN CNC TURNING AND CNC MILLING GEAR WHEEL

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used for mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the optical fiber fastener which accessories used in electronic. They were made by brass, optical fiber fasteners are essential components in the field of fiber optics. Optical fiber fasteners play a crucial role in managing and securing fiber optic cables. They are designed with specific features to ensure the safety and integrity of the cables, making them an indispensable tool in the field of fiber optics.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

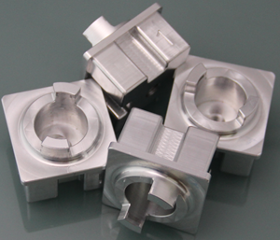

These are accessories for precision machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for printer accessories.After CNC Milling ,deburring, then doing black anodizing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories of printer, which function is for support stand.They were made by aluminum, then use CNC Milling machine to process, then doing black anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The double anodization process can be used to create a protective anodization layer on various parts of a consumer electronic product, including top and bottom portions, side walls, and chamfered portions. It’s particularly useful for improving corrosion resistance and wear resistance, and it provides better adhesion for paint primers and glues than bare metal does. The process is not limited to aluminum; it can also be applied to other metals like titanium, zinc, magnesium, and others. However, aluminum is the most common due to its widespread use in consumer electronics and other applications where weight and durability are important factors.Double anodization is a complex process that requires precise control over the electrolytic solutions, electrical current, and time to ensure the desired outcome. It’s a testament to the advancements in materials engineering and its ability to tailor the properties of metals for specific applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

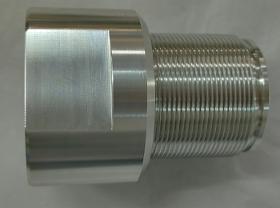

Large mechanical aluminum screw fittings.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories are used for mechanical valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

PA6 (polyamide 6 or nylon 6) is a common engineering plastic that has many advantages: 1, high mechanical strength: PA6 has a high tensile and compressive strength, good toughness. 2. Good wear resistance: Its surface is smooth, the friction coefficient is small, and the wear resistance is excellent. 3. Self-lubricity: When the friction effect is not too high, PA6 can be used without lubricant. 4. Corrosion resistance: PA6 has a good tolerance to alkali and most salts, and can resist the erosion of gasoline, oil, fat, alcohol, etc. 5, excellent electrical performance: PA6 has good electrical insulation, even in high humidity environment can maintain good electrical insulation performance. 6, easy to process: PA6 molding processability is excellent, can be injection molding, blow molding, casting, spraying and so on.These characteristics make PA6 widely used in automotive, electronic and electrical, mechanical equipment and other fields.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are milled by aluminum,which used in architectural decoration industry.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is for products with very high surface requirements.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

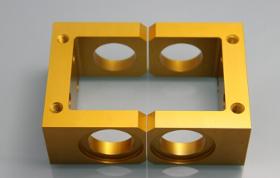

This parts is made by aluminum, after 3-4 axis machining, then, going golden anodize,it is used in the external support of the machine.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used for the machine,made by aluminum, then doing black anodizing.Exquisite appearance and precision tolerance control.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turn-milling compound machining flange

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodizing is an electrochemeical process that creates a durable, corrosion-resistant layer on the surface of metals, particularly aluminum. This layer, known as an oxide layer, can be colored to enhance the aesthetic appeal of the product. The colors that can be achieved through anodizing are varied.The most commonly used anodizing colors include red, blue, green, black, yellow, purple, and orange.The function of anodizing is to enhanced durability, scratch-resistance, and corrosion-resistance.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in industrial filter.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for the precision machinery parts,made by brass and no surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The parts are used for the stent of the machine,they can hold and connect two parts together,provide the function of the bracket.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the base parts used in construction.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quoteResults for

Axis mill - Import exportNumber of results

193 ProductsCountries

Company type

Category

- Milling - steels and metals (78)

- Milling - machine tools (20)

- Machine tools, metal machining - parts and accessories (7)

- Machine tools - metal machining (4)

- Steels and metals - machining (3)

- Mechanical engineering - custom work (3)

- Precision mechanics (3)

- Couplings, mechanical (2)

- Flour milling - machinery and equipment (2)

- Machine tools, metal shaping - parts and accessories (2)

- Sawmills - machinery and equipment (2)

- Turning - steels and metals (2)

- Aluminium alloys (1)

- Aluminium coatings (1)

- Automobiles (1)

- Bicycle accessories (1)

- Bridges - construction (1)

- Bronzing - steel and metals (1)

- Components and parts for large household appliances (1)

- Control switches - electric (1)