- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation of lines

Results for

Automation of lines - Import export

ENOL FOLIEN GMBH

Germany

Our foil packaging for bread and bakery products is available as bags for filling by hand or machine and also as flat foils for your automated packaging lines – the perfect protection for uncut / cut bread, toast, cake, cookies, bread to heat up as well as croissants. Available foils are PP (OPP plain, OPP Coex, PPCast) LDPE laminations according to your requirements – also with PET / PA to meet requirements regarding barrier for freshness. The raw materials are special type for the use regarding bread and bakery products. The flat foils are made suitable individually for your machines to ensure a proper packaging process without any disturbances / interruptions. Our foils are certified as food safe are steadily checked reagarding possibilities to sterilisation, stability as well as stability of the seams. bag sizes, foil widths, rapports and materials acc. to your specifications unprinted or printed up to 10 colours in good flexo- or gravure printing quality Following bag...

Request for a quote

COPIER MACHINERY

Netherlands

Pipe beveling and cutting is way faster end efficient with electrically height-adjustable roller benches. Our TRB roller benches are highly stable and have two control options manual and automatic for very heavy pipes or automated pipe operations. TRB roller benches are easy to adjust for different diameter and reduces the production time. Also, automatic TRB can be integrated into a fully automated production line. Copier Machinery also designs roller benches with measurement and pipe push up system, especially for pipe cutting. Suitable for pipe diameters up to outside diameter 56”, with a length option up to 12 meters. All TRB roller benches are designed and manufactured by Copier Machinery, and they are scalable upon special requests and requirements.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The EBATmètre® is a device for measuring height clearances. It is principally used to measure the moving parts of a mechanical watch movement.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

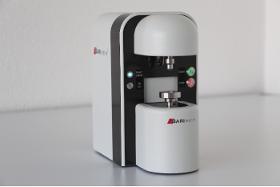

The NEOvario is a high-technology device, which is completely compact and integrated. The measuring devices will meet the demanding needs of torque and force measurement fields. ACCESSORYS : - Universal Digimes - Universal sample holder for watch movement - VARIOweight - Measurement standard - Adjustable angular support - Anti-vibration table

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

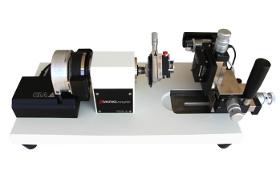

VARIOcouple® The VARIOcouple® apparatus for torque and force measurement manufactured by CLA is a very precise instrument mainly used in development laboratories of watchmakers. This instrument allows quantifying and analyzing small torques and forces generated in low stress systems. ACCESSORYS : - Universal Digimes - Universal sample holder for watch movement - VARIOweight - Measurement standard - CLApt1000 - Temperature sensor - Adjustable angular support - Anti-vibration table

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automation with direct impact: BARImètre® Automat can absorb 150 barrels per measuring channel (4 channels max). Load your machine, press START and the Automat will do the rest.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The BARImeter® is a precision metrology device that offers a great flexibility in the measurement of microtechnical, horological and medical parts. In particular, it is possible to measure small friction torques in both directions of rotation as well as holding torques. Examples: - Barrel measurement - Friction-wheel measurement

Request for a quote

PRESSTECK S.P.A.

Germany

Guide tubes for solenoid valves, deep-drawn from stainless steel. Tightest tolerances, high quantities

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

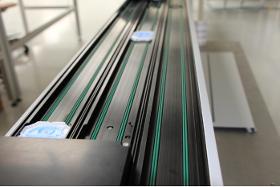

- Standard shuttles 48x48 mm - RFID technology - SMS management by routing software OMS - Mainly used by watchmaking sector and microtechnology - Intelligent conveyor for industrial automation with production traceability Examples: - Assembly line for balance-springs - Assembly line for barrels and the control - Flexible transfer line

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Dosing and mixing systems in the personal care industry are characterised by high plant safety and flexible handling. With IFA systems for the personal care industry, the main focus is on the processing of a large number of different raw components and hygienic cleaning after a recipe change. Mixing and dosing systems supplied by us range from semi-automated to fully automated production lines. IFA Technology considers your individual requirements and builds customised plants and systems for the personal care industry.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the home care industry. Dosing and mixing systems in the home care industry are characterised by high plant safety and flexible handling. Our main focus is on the processing of a large number of different raw components and on hygienic cleaning after a recipe change. We supply systems for the home care industry from semi-automated to fully automated production lines. Based on your wishes and requirements, we develop customised solutions that meet the highest quality standards.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

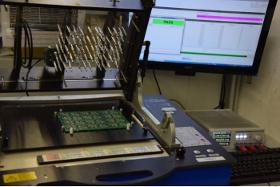

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

control panels, control cabinets, pneumatic systems, pneumatic systems, control units, pre-assembled pneumatic modules for machines and plants in automation technology factory automation assembly lines test benches Also for automotive applications such as brake test benches, assembly robots, conveyor belts. Design, layout, assembly, plug and play delivery. We are also happy to use components according to the parts list, specifications or customer specifications.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MTA ROBOTICS AG

Switzerland

The laser MRC500 is the larger robotic cell that supports point to point laser soldering from above. The standardized platform is based on a flexible and modular concept that can be adapted to a range of processes from fully-automated in-line to stand-alone semi-automated processes. The frame of the laser MRC500 is designed to ensure the safety of the operator during the laser soldering process. Furthermore, it also provides maximum accessibility to the working area. The laser robotic cell is only equipped with mta MLH45 laser head. The main features of our laser MRC500 include: Welded frame construction 3-axis Cartesian robot 500x500mm working area Industrial PC controller with Embedded Windows® operating system Intuitive menu-driven mta MotionEditor software

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

With the ever increasing automation of assembly lines, users are finding that values for absolute linearity are steadily gaining importance. Unlike independent linearity, for absolute linearity the reference slope is fully defined (Fig. 8) so that there is no need for subsequent system trimming. The definition of an index point establishes a relationship between the mechanical input value (travel or angle) and the output voltage. Potentiometers whose linearity is defined by these criteria can be installed without a need for subsequent adjustment. As with independent linearity, it is best to determine the absolute linearity of a potentiometer by comparing its output with that of a master potentiometer. With absolute linearity, it is frequently necessary for the tolerance fields to be stepped. Fig. 9 shows a practical example. Fig. 8 Fig. 9

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

MINEBEA INTEC GMBH

Germany

VisioPointer® reliably automates inspection processes in food packaging lines using leading vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime, and optimize the production. As a plug and play vision solution, VisioPointer® makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R40 ✅ Industrial robot applications for components up to 1 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quoteResults for

Automation of lines - Import exportNumber of results

96 ProductsCountries

Company type

Category

- Automation - systems and equipment (17)

- Electrical & Electronic Components (4)

- Bearings - ball, needle and roller (3)

- Confectionery - machinery and equipment (3)

- Optical measuring equipment (3)

- Extrusion, plastics - machinery (2)

- Food Processing (2)

- Food industry packaging machinery (2)

- Forming - steels and metals (2)

- Goods handling systems, continuous (2)

- Hoses, pipes and tubes - plastic (2)

- Mechanical engineering - custom work (2)

- Strapping, metal (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Anti-corrosion coatings (1)

- Autogenous welding machines (1)

- Bakery - machinery and equipment (1)

- Business Consultancy (1)

- Cable ducts (1)

- Cables, high-voltage (1)