- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation design

Results for

Automation design - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

TCM - THOMAS CONSTRUCTIONS MECANIQUES, developer of innovations, designs and produces industrial insect breeding, feeding and processing facilities for the agri-food industry. This custom-made automated and semi-automated equipment is designed for insect breeding and processing to produce insect proteins for animal and plant nutrition. These modular units are ideally suited to insect breeding in vertical farms, in fully automated or semi-automated industrial facilities specialising in the production and manufacture of insect proteins

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

PAW INDUSTRIAL DOOR SYSTEMS

Turkey

PAW-ROBO high-speed rolling shutters work in harmony with all kinds of automation systems of new generation factories that produce with the latest technology. It adapts perfectly to the fast production line in factories that produce without human touch. Paw-Robo offers unique solutions in its field thanks to its adaptation to automation systems and its design, high opening and closing speed, safe and long-lasting maintenance-free structure. Thanks to the special selection Tarpaulin system, its resistance against welding slag has been increased.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The RESISTOMAT® model 2311 has been designed and optimized for high-speed applications in automation systems. Up to 100 measurements per second can be achieved. It works on the basis of the welltried four-wire measurement method in which test-lead resistances and contact resistances are eliminated. The instrument leads are monitored for damage by a built-in open circuit detector. A 2-way and 4-way comparator with switching outputs is available for classifications and selections. Of course, temperature compensation is available for any test object material. Specific temperature coefficients can be entered. Temperature recording takes place using a PT100 sensor or a temperature transmitter (pyrometer) with an analog output. A special circuit for protecting the measurement input when measuring inductive test objects has been developed to prevent damage to the meter from voltage peaks produced when the test object is disconnected.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Hygienic design for food, cosmetic and pharmaceutical applications ▪ Easy integration into automated processes due to compact design ▪ Length and weight savings compared to existing pumps ▪ Short cycle times ▪ Non-destructive dosing of solid containing materials with diameter of up to 20 mm ▪ Volumetric dosing and filling, regardless of viscosity ▪ For low to high viscosity materials ▪ Long service life even with abrasive and shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Precise filling with high repeatability ▪ Linear relation between dosing volume and rotational speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ FDA compliant elastomers ▪ Wetted components are autoclavable ▪ Stainless steel ▪ Optional flushing connection for optimum results with CIP ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

MEDIZIN- UND LABORTECHNIK ENGINEERING GMBH DRESDEN

Germany

The FIA system of MLE GmbH Dresden is an automated analytical system designed for laboratories of water and environmental analysis. Parameters of samples are photometrically measured with standardised procedures. The applied technique of flow injection analysis has been become a standard method for ion analysis of aqueous samples, food extracts and eluates from soil. According to your needs the modular system design ( FIAmodula and FIAcompact) enables customized system configurations. Already existing systems can be expended to fulfill new laboratory requirements.

Request for a quote

CRYOSNOW GMBH

Germany

• Especially for automized applications • Very short, compact design, overall length including short flat nozzle 361 mm (14.2") • Installable as extension of the last axis of the robot • Overall weight including short flat nozzle 2.7 kg (6.0 lb) • No water condensation due to thermal insulation • Process reliable and wearless in permanent operation • Jetting width up to 125 mm (4.9") • For the cleaning of big surfaces in pretreatment before painting • For use with different nozzles

Request for a quote

CRYOSNOW GMBH

Germany

• Especially for automized applications • Very short, compact design, overall length including short flat nozzle 330 mm (13") • Installable as extension of the last axis of the robot • Overall weight including short flat nozzle 2 kg (4.4 lb) • No water condensation due to thermal insulation • Process reliable and wearless in permanent operation • Jetting width up to 125 mm (4.9") • For the cleaning of big surfaces in pretreatment before painting • For use with different nozzles

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce low volume turnings to flowable chips- at the source. Continuous low volume metal scrap reduction at the source. Metal crushers are the economical solution for processing stringy and bulky turnings into flowable chips. This piece can be integrated into existing equipment or free-standing. PRAB’s automated scrap removal systems are designed for volume reduction of metal turnings. The comprehensive focus on chip processing provides metalworking companies with an automated, safe and cost-effective way to process all kinds of metal scrap. The first step in this operation is to create flowable chips from metal turnings with scrap handling equipment. The Horizontal Axis Crusher processes low volumes of stringy and bulky metal turnings. This scrap metal recycling equipment is typically mounted on a stand or heavy-duty cart which fits on the discharge of the conveyor off the machining center

Request for a quote

TIRAS TECHNOLOGY

Ukraine

Addressable manual call point for automation controlDETECTO BTN100 is an addressable fire automation call point designed to operate as part of the Tiras PRIME A system. It is installed within the protected premises and sends an activation signal to the control panel according to a pre-configured script. A special feature of DETECTO BTN100 is the "electronic fixation" option. If the option is enabled, then after pressing the button, it will remain in the activated state until it is "reset" from the control panel. If the option is disabled, the button can be pressed any number of times, restarting the configured automation script.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Designed to perform welding inspections on cylinders up to a diameter of 250mm, the AIS231 is a real time system designed to be automated that can also be installed with an ADR module (depending on the client requirement). It is equipped with a shielded cabinet for up to 450kV depending on the power of the generator installed, a flat panel, a 2 axis manipulator, a motorized door, and more. To ensure a great and easy environment of work, the control desk will carry a 19’’ computer with the Inspection suite of software installed allowing the automation of the process which will fastened the everyday inspection.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Production line real time system x-ray solution First real time system developed by Balteau including a ADR module and completely made to work on production line. The AIS500 has been designed to do automated inspection in a wide variety of industry for component from small to middle size. Thanks to the bar code scanners on both ends, the AIS500 will recognize the component and start the inspection without any action from the end user, automting completely the process. Composed of a shielded cabinet, a manipulator, conveyors In & out, an x-ray generator and tubehead from 160kV to 225kV, a flat panel & much more, the AIS500 is the answer to any business who wants to inspection their components from their production line at any stages of the manufacturing.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,950 kN. Size of the platens 450 x 450 mm. Injection volume 1,000 cm³. The H49 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. An optimized cycle time. etc

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 3,100 kN. Size of the platens 550 x 550 mm. Injection volume 1,000 cm³ or 2,000 cm³. The H59 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. Optimized cycle time. etc.

Request for a quote

KELVION HOLDING GMBH

Germany

Our brazed plate heat exchangers offer customized solutions for a wide variety of applications. Thanks to the automated production and compact design of our brazed plate heat exchanger series, we can put together an individual heat exchanger for you within a very short time. The latest technology and decades of experience of successful applications guarantee highest quality, cost efficiency and reliability.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

ThermoView TV40 is a high-performance industrial thermal imaging system for fixed installation designed for factory automation applications. It integrates a visible-light camera and software for temperature control, monitoring, and data archiving. • Wide temperature range: -10 to 1200 °C (14 to 2192 °F) • Rugged aluminum housing, IP67 (NEMA 4) • Ambient temperatures to 200 °C (392 °F) with high-temperature enclosure • Air purge and accessories available • IR-Fusion technology: simultaneous thermal and visible sighting • Remote motorized focus • 320 x 240 and 640 x 480 focal plane array • 9 or 60 Hz models available • GigE Vision interface • LAN/Ethernet with PoE for communication with the camera provides access to Ethernet, Web server and ThermoView Software • Multiple field interchangeable lens options • 2-year warranty

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVOSIM

Turkey

Custom Software Development Process Monitoring and Automation solutions are designed to streamline the software development lifecycle by automating key processes and providing real-time monitoring capabilities. These solutions help software development teams manage projects more efficiently, reduce errors, and improve overall productivity. The system automates various stages of the software development process, including requirements gathering, code generation, testing, and deployment. It offers customizable workflows and task management features to ensure smooth project execution and collaboration among team members. With built-in monitoring and reporting tools, the solution provides insights into project progress, resource utilization, and performance metrics. It enables stakeholders to make informed decisions and optimize development processes for better outcomes.

Request for a quote

GAICTECH

Spain

The Cutting and Gutting / Nobbing Machine is specifically designed for the automated de-heading and gutting of pelagic fish species such as sardines, horse mackerel, and mackerel, crafted from durable stainless steel AISI 316-304 for longevity and food safety. Capable of processing up to 350 fish per minute in a standard setup, and optionally up to 500 fish per minute depending on the fish type, this machine offers versatility with options to cut just the head or both head and tail. It features transport buckets designed to accommodate varying fish sizes and desired product outcomes, using sharp circular blades for precise cutting and a vacuum suction for efficient gut removal, with options for internal or separate waste storage. The machine includes an easy-to-adjust cutting regulation system to cater to different fish sizes and an upper oversight system that immobilizes fish during processing, ensuring consistency and quality.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Automated line is designed for the production of rectangular marshmallows, cylinders, braids (1-4 colors), etc, using starch by extrusion.

Request for a quote

KEDY

Turkey

Introducing the cutting-edge K12200 180 Degree Mold Upender from KEDY, the ultimate solution for your manufacturing needs. This machine is equipped with advanced features such as PLC technology for smooth and precise speed control, and limit switches and a light barrier for added safety and accuracy. The patent-pending design allows for the efficient upending of molds or workpieces all at once, increasing productivity and reducing downtime. Fully electric, plug-and-play, and easily automated, this technology is designed to integrate seamlessly into your existing production line, taking your manufacturing process to new heights. With its safety features, it guarantees safe operation and reliability in your manufacturing process. Contact us now!

Request for a quote

PKO-SURA COMPANY

Russia

Highly automated machines is designed for dosing of dough of various shapes and sizes without or with filling from different confectionery products on a baking pan by extrusion: -shortbread dough (hard or soft); -gingerbread dough; -dough for oatmeal cookies; -biscuit dough; -protein mass (souffle sweetmeat, pastille, marshmallow) The two-hopper mechanism of Сура СД and Сура СДУ depositors ensures the dosing of dough for double-color products or single-color filled products. All Сура С, Сура СД, Сура СДУ machines in standard version are equipped with mechanisms for rotation of draw plates and movement of the conveyor in the vertical plane. Сура СДУ universal depositor can be equipped with a diaphragm cutting unit where the diaphragms can be arranged both in single row and in staggered rows. Possibility to equip any Сура С, Сура СД, Сура СДУ machines additionally with a string cutting unit given that the frame of all machine s are equipped with the connection elements.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Intelligent manufacturing Full automation Custom design For TIG, MIG, Plasma or other welding process

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc help our customer in impeller pump manufacturing industry to develop the laser welding production procedure. Better sealed laser welding quality to let the impeller pump performs high efficiency and increase productivity. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc helps our customer to develop the laser welding automation system in Golf clubs manufacturing industry. Integrated with Fanuc robot system and Rofin laser, we provide a total solution for our customer both in laser welding and laser cutting. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc ServoArc PT-200s is ready for sell. It is a mini positioner that specially designed for automated welding. PT-200s adopts with servo motor and multi-functional CB-500 controller to provide the most stable rotation. It’s easy to build your own welding parameter library that significantly improves welding quality and increases production yield in a short time. • Excellent graphic user interface controller • Uses 20-bit servo motor to achieve 0.1° rotation accuracy • Speed of 0.01 ~ 30 rpm with constant torque & rotation stability • Tilting range from 0 ~ 120°, manual adjustment • Floor type structure for convenient loading/unloading of weldments - create welding flexibility • High frequency interference protection • Spindle through hole allows delivery of shield gas

Request for a quote

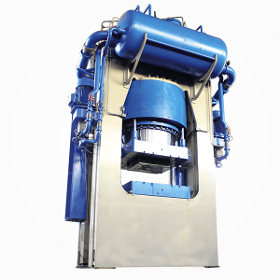

OZKOC HYDRAULIC MACHINE CO.

Turkey

Cold crushing of materials leads to positive structural properties. This process requires high tonnage. high tonnage presses require high strength values, less flexibility and maximum rigidity. It is not only necessary to have a high press force, but also to work quickly and quickly. High forces and speeds bring large hydraulic systems and heavy mechanical disruptions. Their safe and smooth control is the most important part of your press. If the press mechanics is not designed correctly from the beginning with its hydraulics and automation, very serious design errors that will occur in the future can cause very serious costs in these presses. Please call us for a high tonnage crushing press, we are ready to serve you with 56 years of experience.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quoteResults for

Automation design - Import exportNumber of results

45 ProductsCountries

Company type

Category

- Automation - systems and equipment (3)

- Conveyor systems (3)

- Laser - cutting and welding machines (3)

- Integrated logistics (2)

- Presses, hydraulic (2)

- Alarms - security devices (1)

- Applicators for adhesives and glues (1)

- Bakery - machinery and equipment (1)

- Beverage industry - machinery and equipment (1)

- Blast cleaning equipment (1)

- Business Consultancy (1)

- Confectionery - machinery and equipment (1)

- Customer relations management software CRM (1)

- Doors, industrial (1)

- Dosing pumps (1)

- Drainage systems and equipment (1)

- Food industry - machinery and equipment (1)

- Gas detectors (1)

- Goods handling systems, continuous (1)

- Heat exchangers (1)