- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic roller

Results for

Automatic roller - Import export

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Soft turn of the bundles Low maintenance Optimal access Very quiet operation Intrinsically safe machine, protection door-less concept Bypass without bundle turning, manually Upstream and downstream interlocks with complete plug connection In conveying direction left or either right Power cable, length 3m OPTIONAL: Bypass without bundle turning, automatically OPTIONAL: One pop-out roller on entry side OPTIONAL: Machine movable Table height steplessly adjustable Many specific options available, easily configurable

Request for a quote

PRESSTA EISELE GMBH

Germany

A double head mitre saw with disappearing blades specifically studied for the tubular steel shapes. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 45° and 135°. It is equipped with the system TS 690. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Speed of rotation of the blades, variable by means of a frequency converter (inverter). Automatic shifting of the support plates of the profile once over the cutting cycle. Dynamic protection guards for a total covering of the cutting area. Blade lubrication cooling system with electric pump. Coolant liquid vat with extractable pump for vat cleaning. Cutting deepth stop device. Intermediate workpiece support automatically operating Mobile roller conveyor with pneumatic clamp for section support Compressed air treatment unit (filter/reducer/lubricator)

Request for a quote

VARLET MACHINES

France

Manual skinning machine specially designed for flat fish such as sole, small smooth skate wings and for large fresh or smoked fillets. The V368 is versatile and can be used by fishmongers, at the market or in supermarkets, etc. It is also very compact (290 cm working width) and can be placed on its stand or on a table. The machine is equipped with a skinning shoe, which means that no consumables are needed. Finally, the bearing roller, offered as an option, facilitates the user’s work. Main features: - Easy to operate and Plug & Play - Easy to clean - No consumables - No specific maintenance - 100% stainless steel - Work gloves supplied - Possibility of 220 V single-phase power supply - Support adapted to receive the machine lengthwise or widthwise. Options: - Stand on wheels, with box for skins - Bearing roller - Automatic water injection

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4), equipped with Senso Technology.

Request for a quote

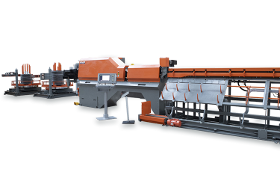

SCHNELL SPA

Italy

Automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Capacity 2 Ø 16 mm (#5) Max pulling speed 200 m/min (660 ft/min) Straighteners (horizontalsverticals) with electronic adjustment and independent position for the 2 wires Motorized wire change unit (Optional) Prestraightening Feeding Unit (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut and stock precut bars made of fast automatic straighteners with rollers (such as RETA) and coil processing up to Ø 20 mm. Pulling speed up to 300 m/min. The plant is fully customizable and modular thanks to a wide range of available accessories. Fast Coil change patented system of automatic horizontal wire change (Optional); Straighteners (horizontalvertical) with electronic and independent setting for double wire feeding; Cutting with Brushless motors with adjustable wire guide, fixed and mobile cutting blades; Rollers for the extraction of the last part of the coil; Teleassistance.

Request for a quote

RHIMEX.COM

Netherlands

In addition to the manually operated roller blinds, we also supply electric roller blinds. These roller blinds are available with an easily adjustable motor, a Somfy motor or a programmable motor. Can be controlled remotely Reliable and durable because the electric roller blind is more resistant to misuse compared to the manually operated roller blind Automatically controllable by programming function

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This roller conveyor is ideal to prevent the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices. At the same time, there is no need for personnel to hold the packages along the device as the packages move through the device. • It has a stainless steel case and easily rotating plastic bearings. • Dimension (L x W x H) 560x 260 x 50 / 150mm (Height Adjustable) • Weight 4 Kg • Designed for 05GD, 08GM and 09GM model sealers.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This roller conveyor is ideal to prevent the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices. At the same time, there is no need for personnel to hold the packages along the device as the packages move through the device. • It has a stainless steel case and easily rotating plastic bearings. • Dimension (L x W x H) 760 x 260 x 50 / 150mm (Height Adjustable) • Weight 8 Kg • Designed for 10GM and 20GM model sealers.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This roller conveyor is ideal to prevent the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices. At the same time, there is no need for personnel to hold the packages along the device as the packages move through the device. • It has a stainless steel case and easily rotating plastic bearings. • Dimension (L x W x H) 1110 x 260 x 50 / 150mm (Height Adjustable) • Weight 8 Kg • Designed for 45GM, 46GM, 50GM and 60GM model Pouch Making Sealers.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

- Standard perforation devices as module system at reasonable prices with manual or automatic roller adjustment - Perforating devices adapted to your machine and its special conditions - Perforation systems with driven rollers - Hot perforating systems for foils and nonwovens.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CK 412 is an automatic saw blade machine which is ideal for cutting operations of the PVC glazing beads at 45°. Adjustable saw blade feeding speed Pneumatic saw feed by pushing button Equipped with 2x pneumatic vertical clamps Automatic return to start point of the process Twin blade design 8 glazing beads can be cut simultaneously using single mold without problems STANDARD ACCESSORIES 1x Ø 200 and 1x Ø 103 mm saw blades KN 152 roller conveyor Air gun OPTIONAL ACCESSORIES Clamping device for special glazing beads Additional saw blades Digital Roller Conveyor with Automatic Stop (SKN 301) SKN 300, SKN 450,SKN 600 conveyor SKN 301, SKN 451, SKN 601 conveyor Videolar TECHNICAL SPECIFICATIONS 1200 W x2 400V AC 50~60 Hz 3.000 D/dak. RPM D1:103 mm D2:200 mm d:30-32 mm 6~8 Bar 35 Lt. / dak. 54x113x124 cm 168 kg 134 kg

Request for a quote

YILMAZ MACHINE

Turkey

Machine is ideal for welding process of PVC plastic profiles at four corners. Fully automatic four corner welding of PVC window profiles at an angle of 90° Welding of a complete window frame or sash in one cycle All profile related welding parameters are individually programmable User-friendly operating system compatible to all optimization programs Parameters are set easily by means of 8’’ LCD color touch screen Automatic line can be made by combining with Cooling Unit (SA 250),Corner Cleaning Machine (CNC 608-610) and Rotating Robot (SA 260) Automatically setting of standard (2 mm) or seamless (0.2 mm) welding options Long time of Teflon using period by means of the roller system Automatically discharging of the frames after welding operation Colored and white profiles selection modes Saving of time by means of practical mold change system Operator safety barrier Adjusting the heat between 0-300°C via electronic thermostat Minimum welding measurement : 400 x400 mm

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quote

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration High-end Standard 6 sealing unit Dispenser variably mountable Intuitive user guidance via colored touch panel Electromechanically driven aluminum rollers ensure an optimal product transport Continuously adjustable conveyor speed from 0.2to 1.0m/s Bundle positioning via increments by metrical input of the strapping positions Open design without protective coverings - CE marking inclusive conformity declaration Infeed side guidance Extremely low energy consumption

Request for a quote

MOSCA GMBH

Germany

•Corrosion-resistant ultrasonic sealing system with electronic self-calibration •High-end Standard 6 sealing unit •Wear-free DC drives with integrated electronics •Stepless turnable control panel for many-sided operation •Adjustable strap tension via control panel •Switching from maximum to material-friendly Ecospeed in the control •Quick strap coil change •Automatic strap threading system •Strap end detection with ejection of remaining strap •Automatic strap loop ejection •4 castors, 2 of them lockable (Ø 80 mm) •CE marking inclusive conformity declaration •Potential-free contacts to upstream and downstream machines •Continuously adjustable conveyorspeed from 0-1 m/s •Parameter control panel for setting strapping parameters •Selector switch for pass, single, double or multiple strapping •Machine completely corrosion-resistant (main use of V4A stainless steel) •IP 56 protection class design •Sensitive components (e.g. motors) are equipped with additional covers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUANGDONG PINLONG PRECISION TECHNOLOGY CO., LTD.

United Kingdom

1. Vacuum transfer, staggered vacuum transfer wheels and structure which ensures boards transfer smoothly. 2. Multi-sections vacuum volume control, automatic adjusting according to different boards size. 3. Automatic locking & position location, for printing plate. 4. Precise integral anilox roller & rubber roller/chamber blade system rise and fall structure, ensures perfect ink transfer and avoid shake when printing. 5. Registration with servo motor, lateral ball screw rod adjusting. 6. Rubber roller & anilox roller fast changing design. Chamber doctor blades and rubber roller are available, optional. 7. Anilox roller automatic self-wash device, much more convenient for circulation washing. 8. Automatic back to “zero” after washing printing studio. 9. Double diaphragm pump, and automatically ink recycling system, can reduce ink waste, and make ink recycling faster. Printing unit can equipped with hot air/IR dryer system.

Request for a quote

RISUS MACHINES

Turkey

-It is designed for assembly and test of roller shutters. -Automatic turning mechanism -2 Axis motor controlled -Electro-pneumatically controlled -15.6” Pc controlled touch screen Remote control service

Request for a quote

RISUS MACHINES

Turkey

-It is designed for the processing already cut aluminium profiles that should be brought together and be locked. -Fixing the caps with staples made out of steel. -2 axis servo motor motion control -Production capacity of 240pcs/8 hours. -15.6” Pc controlled touch screen

Request for a quote

KONYA MILL

Turkey

This is the main part of the mill machinery factory which grinds the wheat. We have two types of Rollers: Manual and Automatic system with PLC. The grinding unit also includes the other machines as semolina grinder. For more information, pictures and videos you can both contact by mobile or whatsaap or email: export.milltek@gmail.com Also you can refer to our website by clicking the following link: http://www.millteknoloji.com/urunler/47-ogutme-unitesi/

Request for a quoteResults for

Automatic roller - Import exportNumber of results

22 ProductsCompany type

Category

- Industrial cutting machine tools (3)

- Sealing and wrapping - machinery and equipment (3)

- Packing and packaging - machinery and equipment (2)

- Roller shutters (2)

- Cardboard and cardboard products - processing machinery (1)

- Conveyor systems (1)

- Electric roller blinds (1)

- Fish processing - machines and equipment (1)

- Flour milling - machinery and equipment (1)

- Food Processing (1)

- Labelling machines (1)

- Perforation of rubber and plastic (1)

- Welding robots (1)