- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic lubrication

Results for

Automatic lubrication - Import export

ALKIM PETROKIMYA

Turkey

It is a high-quality automatic transmission lubricant with a wide temperature range, which facilitates gear in challenging driving conditions and is manufac tured in accordance with the standards required by performance. With its high Viscosity index, it provides extra performance while maintaining fluidity at very low temperatures and lubricating at high temperatures.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction and rolling bearings, chains, joints or slideways at higher temperatures For conveying systems under radiation heat in painting, stoving and drying systems, travelling grates in firing systems Dry lubrication at temperatures above 200°C Lubrication of elastomers and plastics not resistant to mineral oil Advantages and benefits Highly suitable as a high-temperature lubricant Very effective due to finest, homogeneous MoS₂ distribution in the oil Resistant to water and many chemicals, fuels, lubricants and hydraulic oils For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. If at all possible, avoid excess. Observe the machine manufacturer's instructions. Assess the lubrication frequency

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, ejector pins, clamping and drying frames or slideways at temperatures up to 250°C or under influence of water, for example conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Outstanding oxidation properties Resistant to water and steam Good creep properties Outstanding adhesion and lubrication effect with no tendency to drip No formation of hard residues Extreme wear protection through Moₓ-Active Resistant to ultraviolet radiation Also available as spray version OKS 3541 For optimum effect, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Stir/shake well before use. Apply OKS 354 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system to locations to be lubricated. Spray OKS 3541 on evenly. Allow excess to drip off and wait for lubricant to penetrate

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of parts subject to high levels of stress such as plain, roller and rod-end bearings, spindles and guideways Advantages and benefits Highly suitable for high-stressed lubrication points Highly effective caused by optimal combination of components Saving of maintenance and lubrication costs by reducing downtimes and corrective maintenance Reduction of down times due to wearFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610 or OKS 2611 universal cleaner. Before filling for first time, remove anticorrosion agent. Fill bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50 000) and their housings should be filled completely. The bearing and machine manufacturer´s instructions should be observed. Subsequent lubrication at the lubrication nipples by grease gun or by automatic lubrication system.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed chains, joints or slideways at higher temperatures For conveying systems running beneath radiated heat, in baking and drying lines in the foodstuffs industry Dry lubrication at operating temperatures above 200°C The synthetic oil content evaporates odorlessly without leaving residues, while the solid lubricant content are left behind to carry out dry lubrication Advantages and benefits Highly suitable as a high-temperature lubricant Highly effective due to homogeneous distribution of the finest graphite throughout the oil Versatile application as a liquid lubricant under high temperature conditions Resistant to water, chemicals, fuels, lubricants, and hydraulic oils NSF H1 registered For best results, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water Duolabel Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water OKS 370 is suitable for use with the OKS Airspray system Also available as spray version OKS 371 Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, clamping and drying frames, and slideways at higher temperatures For conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Non-contaminating liquid lubricant for higher temperatures Highly effective due to optimum wear protection, outstanding oxidation behaviour and good creep properties Absolutely resistant to water and steam, inert with respect to acidic media Outstanding adhesion and lubrication effect with no tendency to drip and no formation of hard residues For best results clean the cold surface, first mechanically and then with OKS 2610/OKS 2611 Universal Cleaner. Apply sufficient amount onto the lubrication areas with brush, dip oiler, dipping or suitable automatic lubrication systems. Let excess drip off and let product affect before the beginning of operation. Instructions of the machine manufacturer have to be considered. Relubrication period and amount should be stated

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, fringe bearings, hinges, joints, clamping and drying frames or slideways at higher temperatures and loads For conveying systems under radiation heat in painting, stoving and drying systems Advantages and benefits Highly effective due to finest, homogeneous MoS₂ distribution in the oil Emergency running properties through MoS₂ at dry running Outstanding adhesion and lubrication effect with no tendency to drip or dry out Silicone-free For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. Allow excess to drip off. Allow OKS 350 to soak in before operating. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, clamping and drying frames or slideways at higher temperatures Suitable for conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Highly effective due to optimum wear protection and outstanding oxidation properties Resistant to water and steam Good creep properties Very good adhesion and lubrication effect with no tendency to drip Also available as spray version OKS 3521 For optimum effect, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 352 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system to locations to be lubricated. Spray OKS 3521 on evenly. Allow excess to drip off and wait for lubricant to penetrate before resuming operation. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 341 For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

FERPLAST SNC

Italy

STAINLESS STEEL VAC SERIES New series of professional external vacuum packing machine external for counter. Very robust as made entirely of stainless steel. Operation with embossed envelopes or three layered. Perfect for use in restaurants, catering or domestic environment are supplied with CE certificate and manual of use and maintenance. Main features: Working cycle fully automatic, space-saving, self-lubricating pump.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Suitable aftertreatments can render precision O‑rings and X‑rings suitable for specific requirements. Typical requirements are low friction, easier installation (automatic or manual), lifelong lubrication, smooth running and non stick effect. Coating is a process frequently used for surface treatment. The IDG application consultants are available to discuss specific requirements with you.

Request for a quote

KUZEY GLOBAL

Turkey

CMK 85/55-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or multi compartment containers, hinged lid containers, leaking-proof containers, hole-punch containers, egg viyole, flower pots and seeding trays. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors Automatic lubrication of moveable parts which is activated as perthe specified time space

Request for a quote

GRAVOTECH

France

OPEN STRUCTURE The M40 rotary engraver is 8.26x12in engraving area benefits from an open structure that allows larger items to be engraved when needed. Create custom engraving on very long plastic signage plates, electrical labels, thin wood beams, golf clubs, swords, irregular-shape items, and simply use as a sign engraver. GIFT ENGRAVING WITH THE M40 GIFT The M40 Gift includes an automatic lubricant tank and a rotary device to personalize glasses and bottles. The rotary device can be tilted for conical items. Engrave and personalize any flat or cylindrical items up to 4.33in height. BEGINNERS ROTARY ENGRAVER Control and adjust your work with our dedicated Gravostyle™ or ABC engraving software, thanks to several options. The M40 comes with an auto-centering jig and a laser beam (Point & Shoot) to help you place the item to engrave, while the engraving software automatically picks up its position. The included Gravogrip™ table firmly holds the item without leftover residue on it.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FILLPACK GMBH & CO. KG

Germany

2 x 2 dosing pumps with motorised individual adjustment from 0 – 500 ml nearly maintenance-free machine with automatic central lubrication system Fully-automatic cleaning of filling machine (CIP/SIP) Quick and simplified format change (15 min.) Two filling machines enabling alternate operation/cleaning Heatable hopper (35°C – 95°C) Diversion and feeding of filled jars to the cooling zone Film applicator station Sealing station Multi-transport plate for all current jar diameters

Request for a quote

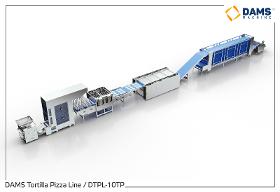

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

ACEMAL NV

Belgium

- Injection device for all kind of waffles; - Robot destined to the automatic removal of waffles; - Automatic brushes; - Cleaning system; - Lubrication system of the waffle irons.

Request for a quote

UNIL LUBRICANTS

Belgium

Matic LT Synthetic, long-life lubricant for automatic gearboxes and some hydraulic systems of freight lorries, passenger cars, buses and industrial vehicles. It is also suitable for some power steering systems and can be used as HV ISO VG 32 hydraulic oil. It cannot be used for continuously variable transmission systems (CVT). Benefits: Long lifespan thanks to a very high oxidation resistance. Excellent friction properties. Good resistance to high temperatures. Permits far-reaching rationalisation.

Request for a quote

LVD

Belgium

For cost-efficient CNC punching in a reliable and user-friendly machine there’s the P-Series. The ram system, rugged frame and CNC control ensure tight tolerances and consistent punching accuracy. The control offers simplicity for operator input of critical dimensions. The P-Series is ideal for shorter production runs, prototype production, job shop environments and cellular manufacturing. KEY FEATURES Flexible 33-station thick turret Quick-change die holders Wheel, tapping and full form tool capabilities Smart Clamp ensures the smallest possible no-punch zones 25 mm feed clearance for more forming capacity Easy-to-use Fanuc CNC control PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software ABS automatic tool lubrication MODELS P 1212 (20 ton – 1250 x 1250 mm) P 1225 (20 ton – 1250 x 2500 mm) P 1525 (20 ton – 1524 x 2500 mm)

Request for a quote

LVD

Belgium

The VX-Series is the choice for production applications demanding high productivity. These full-featured sheet metal punching machines are exceptionally versatile – high hit rates, large feed clearance and powerful control capabilities combine to enable optimal throughput. Full sheet utilization and heavy sheet carrying capacity also add capacity – as do smart features and automation options. It all adds up to punching productivity that is unsurpassed. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy Reduction System minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software ABS automatic tool lubrication

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

designed for various tool interfaces, e.g. HSK, SK, collet chuck slot and short taper equipped with manual or automatic clamping system permanent grease lubrication or oil-air lubrication

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

LUBCON offers the ideal combination of premium lubricants and highly robust, automatic lubrication systems. With more than 40 years experience, we know very well which combination works best and which one doesn’t. This holistic approach helps to avoid issues and will reduce your maintenance costs and machine downtime.

Request for a quoteResults for

Automatic lubrication - Import exportNumber of results

76 ProductsCountries

Company type

Category

- Lubrication equipment and machinery (18)

- Lubricants, industrial (13)

- Silicones (11)

- Bakery and confectionery industry - machinery and equipment (4)

- Forming, rubber - machinery (4)

- Lubricants for cars (2)

- Concrete mixers (2)

- Laser - cutting and welding machines (2)

- Rolling mills - machinery and installations (2)

- Import-export - oil (1)

- Autogenous welding machines (1)

- Bakery - machinery and equipment (1)

- Bakery ovens (1)

- Bearings, ball (1)

- Beverage industry - machinery and equipment (1)

- Chains (1)

- Construction - Machines & Equipment (1)

- Food Industry - Machines & Equipment (1)

- Food packaging (1)

- Greasing equipment (1)