- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic filling machine

Results for

Automatic filling machine - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic flowmeter filling machine is a type of equipment used in the packaging industry for accurately filling liquid products into bottles or containers. It uses a flowmeter to measure the volume of the liquid being filled and automatically stops the filling process once the desired volume is reached. Feature: It is PLC control the flowmeter open and shut off, servo motor driven the filling nozzles moving up and down. Capacity: The capacity of an automatic flowmeter filling machine can vary depending on the model, but typically ranges from 500 ml to 5 liters. Material: Most flowmeter filling machines are made from stainless steel or other food-grade materials to ensure the quality and safety of the product being filled. Speed: The speed of the filling process can be adjusted depending on the viscosity of the liquid and the desired fill volume. Cleaning: Flowmeter filling machines are designed to be easyto clean, with quick-release fittings and removable components

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Semi automatic Pneumatic volumetric Piston Filling machine is available with Single Head or double filling Heads.High quality and famous brand air cylinder ensure the machine work stably and fast.Make the machine suitable for fill viscosity and liquid.This semi-auto machine have 2 working mode for operation,auto and pedal. Feature Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

CDA

France

The K-Line S stands out as an automatic dosing and filling machine designed to accommodate a wide range of liquid types. Its versatility extends to handling various product consistencies, including fluids, foaming liquids, and thick or pasty viscosities. Tailoring its functionality to the viscosity of the intended products, the machine is equipped with a suitable pump. Configured with either a magnetic or mass flow meter, the K-Line S features a pressurized tank renowned for its effective self-cleaning system. Boasting remarkable precision, the K-Line S ensures the automatic centering of products. It is configurable with 2 to 6 filling nozzles, with the option of immersion nozzles for foaming products. The machine achieves an impressive filling rate of up to 3000 liters per hour.

Request for a quote

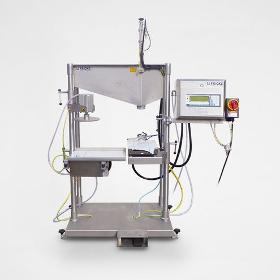

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 22 offers flexible expansion options, supports complex control tasks and MES/ERP connections, and enables remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for foaming, gassing or statically charging liquids, such as cleaning agents, it offers electronic scales, automatic container transport and drip-free under-level filling. Product is fed directly from storage tanks via gravity or pumps. ■ Almost foam-free, calibratable under-level filling ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ simple operation ■ low space requirement ■ can be used immediately just connect energy (electricity and/or compressed air only) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 50 is a semi-automatic filling machine with over and under level valves for the precise filling of viscous to pasty liquids such as paints, varnishes or adhesives. It is suitable for over-level filling into open containers such as cans and buckets as well as for under-level filling into bunghole containers, e.g. canisters, for foaming, gassing or statically charging liquids. ■ a calibratable over-level filling system ■ Thread-cutting, non-drip filling valve ■ an almost foam-free, calibratable under-level filling system ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ Simple operation by one person ■ Filling capacities of up to 10 containers per minute ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for precise filling of foaming liquids, for gassing products or products that load themselves statically, e.g.: cleaning and care products, solvents, chemical liquids, mineral oils, glazes. For the filling of open containers, e.g. canisters. Below level filling, coarse/precision filling valve, does not drip. Product supply via pump or gravity. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic platform weigher for precise filling of low viscous liquids, e.g.: paints, varnishes, dispersions. For the filling of standard container types, e.g. open cans, buckets and canisters. Above level filling for coarse and fine flow. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the Container (Container and valve can be cleaned in approx. 5 minutes by using 1 litre solvent) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 42 enables complex control tasks and MES/ERP connections as well as remote maintenance. Its modular design allows it to be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for viscous to pasty liquids such as paints, it features an electronic scale and fills open containers just above the filling level. The product is fed from storage tanks by gravity or pumps. ■ a calibratable over-level filling unit with travelling valve just above the filling level ■ Thread-cutting, non-drip filling valve ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ The ideal solution for small and medium-sized filling orders ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect energy (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for precise filling of non-foaming liquids, e. g. chemical liquids or mineral oils. For the filling of open containers, e.g. canisters. Below bunghole filling, coarse/precision filling valve, cut threads, does not drip. Product supply via pump or gravity. Direct connection via product hoses to the valve. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

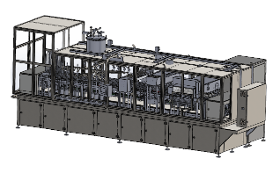

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

It is PLC control the flowmeter open and shut off, servo motor driven the filling nozzles moving up and down. Capacity: The capacity of an automatic flowmeter filling machine can vary depending on the model, but typically ranges from 500 ml to 5 liters. Material: Most flowmeter filling machines are made from stainless steel or other food-grade materials to ensure the quality and safety of the product being filled. Speed: The speed of the filling process can be adjusted depending on the viscosity of the liquid and the desired fill volume. Typically, these machines can fill between 30 and 60 bottles per minute. Accuracy: Flowmeter filling machines are known for their high level of accuracy in measuring the volume of the liquid being filled. They can achieve accuracy levels of +/- 0.5%. Operation: The operation of an automatic flowmeter filling machine is typically

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic rotary piston filling machine is a type of volumetric liquid filling machine used to fill liquids into bottles, jars, or containers at high speeds. It operates by using a rotary motion to move the containers through a series of stations, where each station performs a specific function in the filling process. The filling process involves filling the liquid into the containers accurately and precisely using a piston mechanism that is driven by a rotary motion. The liquid is metered out using the piston, which moves in and out of a cylinder to fill the desired volume of liquid into the container. Once filled, the containers are then moved to other stations to complete the filling process. Some of the benefits of using an automatic rotary piston filling machine include increased efficiency, accuracy, and speed, as well as reduced labor costs and waste. These machines can be used for a wide range of liquid products

Request for a quote

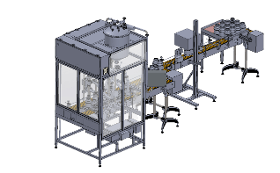

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The piston filler is one of the main product of Npack, most of Npack liquid filling dispenser are applying in the fields of Daily chemicals, cosmetics, Food&beverage,personal care products, pharmaceuticals, Oils products.As piston filling machine are solely based on conventional volumetric technology, these are easy to operate and relatively low cost for the majority of the end-use industries. Piston filling machine is one of the most popular liquid filling machine for its universal ability ,piston filling machine can fill thick and highly viscous products, such as chunky, semi-paste, paste products, also extensively utilized to fill chemical preparations, such as adhesives, greases, epoxies, waxes, and lubricant oils, also an optional for filling thin liquid Widely application of liquids, such as viscous liquid, shampoo, lotion,cream;Food sauce;foamy liquid,hand liquid soap,detergent. High Performance and accuracy,easy operation.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machines are made of high-quality stainless steel, making them durable and easy to clean. 6. Automatic control: Liquid weighing filling machines have automatic controls that detect when the container is full, stopping the filling process. 7.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

For some highly corrosive liquid products, this machine can adapt PTFE pump, PTFE hose and sealing material, so as to avoid the corrosive of the machine 2. The parts in contact with the liquid conform to the GMP standard. When filling, the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent. 3. The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean. 4. This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need. More information: When filling, the filling head presses against

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-OF Automatic Multy Head Overflow Liquid Filling Machine works by feeding the liquid through a specific pump or a top storage tank. Simultaneously, once the feeding is completed, a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filling heads can be increased to meet production needs. It’s ideal for filling low-viscosity, high foamy liquid in the chemical, food, pharmaceutical, and other sectors. Vacuum overflow filler system is for optional,filling nozzles moving up and down by servo motor driving, specially designed overflow filling nozzles.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic drum liquid weighing filling machines are designed to fill drums with liquids using weight sensors and speed control technology. Some of the features of these machines include: Accuracy: These machines use weight sensors to ensure the accurate and consistent filling of drums with liquids. Speed control technology: The machines are equipped with speed-control technology, which allows for the precise and efficient filling of drums with liquids. Ease of use: The machines are designed to be user-friendly, with easy-to-use controls and quick changeover times. Versatility: These machines can handle a wide range of liquids from oils, solvents, chemicals, and other high-value liquids. Safety: The machines have built-in safety features, such as emergency stop buttons and guarding, to ensure operator safety. Low maintenance: Automatic drum filling machines are often designed for low maintenance

Request for a quoteResults for

Automatic filling machine - Import exportNumber of results

93 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (46)

- Automation - systems and equipment (8)

- Packing and packaging - machinery and equipment (7)

- Food industry packaging machinery (6)

- Food industry - machinery and equipment (5)

- Pharmaceutical industry - machinery and equipment (4)

- Agglomeration and emulsification machines for the food processing industry (2)

- Bag filling machinery and equipment (2)

- Chemicals and pharmaceuticals - packaging machinery (2)

- Labelling machines (2)

- Rolling mills - machinery and installations (2)

- Silicones (2)

- Bags, plastic (1)

- Boxes, cardboard (1)

- Cosmetics industry - machinery and equipment (1)

- Detergents and soaps - professional (1)

- Food extracts - machines and equipment (1)

- Laundry detergents for household use (1)

- Livestock raising - machinery and equipment (1)

- Package stamping machinery (1)