- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automated packaging

Results for

Automated packaging - Import export

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

ENOL FOLIEN GMBH

Germany

Our flat foil is used for automatic packaging processes. It is suitable for standard use or special packaging solutions. We deliver the flat foil adjusted to your existing machinery in order to safeguard fast and secure packaging without any disturbances. Our foils are offering longterm protection of your products, especially because of high welding stability. ENOL flat foils can be delivered with or without printing in different materials, like PP (OPP, PPCoex, PPCast), PE (LDPE, HDPE, MDPE), metallised (ALU), pearlised OPP and PET in every width and foil thickness. For each product to be packed you can receive the suitable packaging foil – also laminated with PET or PA in order to provide longer freshness of the packed product or to provide more stability of the foil for industrial processing width, material thickness, rapports according to your requirements for industrial processing food genuine material PP (OPP plain, OPP Coex, metallised OPP, CPP), PE, PET laminated if...

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

ENOL FOLIEN GMBH

Germany

Our foil packaging for bread and bakery products is available as bags for filling by hand or machine and also as flat foils for your automated packaging lines – the perfect protection for uncut / cut bread, toast, cake, cookies, bread to heat up as well as croissants. Available foils are PP (OPP plain, OPP Coex, PPCast) LDPE laminations according to your requirements – also with PET / PA to meet requirements regarding barrier for freshness. The raw materials are special type for the use regarding bread and bakery products. The flat foils are made suitable individually for your machines to ensure a proper packaging process without any disturbances / interruptions. Our foils are certified as food safe are steadily checked reagarding possibilities to sterilisation, stability as well as stability of the seams. bag sizes, foil widths, rapports and materials acc. to your specifications unprinted or printed up to 10 colours in good flexo- or gravure printing quality Following bag...

Request for a quote

IGUS® GMBH

Germany

iglidur® knife edge rollers Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Knife-edge conveyor pulley application example Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Soft stainless steel Hard stainless steel

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

With automatic lines for slicing and packing sausage, ham and cheese products, MULTIVAC realizes the optimal connection of slicers to thermoforming packaging machines and traysealers.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

GORDOPACK GMBH

Germany

For protecting and preserving your goods, flat film packing of Gordopack is your best option. Our flat film of our company covers the needs of a wide range of applications in private households, but also in industry and trade. The flat films are suitable for manual or automated packaging of goods as well as for covering and protecting various goods. The assortment of flat films ranges from asparagus foils, flow packaging films to top sheets. According to our customers' wishes, we also equip the flat films with technical additives and colours Product can range from HDPE/ MDPE/ LDPE/ PCR with straight-cut edges, perforated on roll, needled, with antistatic agent, UV-stabilizer/absorber, symbol marking, Corona treatment and in various colours.

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: from 0,2 mm Spring geometry after consultation Material Stainless steel Copper alloy Customized solutions Coating Additional coatings through external services (e. g. gold-plated, silver-plated, tin-plated) Specialities Highest precision because of laser-welded spring ends Optimal contact properties because of inclined coils Automated manufacturing Customer specific packaging Rapid prototyping

Request for a quote

MICRO-EPSILON

Germany

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Request for a quote

MINEBEA INTEC GMBH

Germany

VisioPointer® reliably automates inspection processes in food packaging lines using leading vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime, and optimize the production. As a plug and play vision solution, VisioPointer® makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

Request for a quote

FILMEX PACKAGING KFT.

Hungary

A heat-shrink film that protects packaged products from various environmental damages. The film softens and shrinks when exposed to heat; the rapidly cooling material then provides good transverse and longitudinal strength to the product. It can be produced as a tube or flat film to meet customer requirements, and can be used also not only for manual heat shrinking but on lines with a heat tunnel for automated packaging.

Request for a quote

CENTER GLOBAL SOLUTIONS LLC

United States

Reliable Supply: Annual programs with comprehensive quality control to ensure just-in-time supply to mass production companies. Certified Quality: Components developed to the highest quality standards, certified at the source to ensure proper sourcing. Cost Reduction: Our goal is to decrease your input costs without compromising current quality standards. Customized Development: From 3D design and prototyping to tooling creation and samples, considering costs, productivity, and material selection. Production Expansion: We support capital investment, production line design, packaging, and automation for a more efficient manufacturing plant.

Request for a quote

NOVOSIM

Turkey

Special Purpose Machinery refers to custom-designed and built machines tailored to specific industrial processes or applications. These machines are engineered to meet unique production requirements and enhance manufacturing efficiency. Special Purpose Machinery encompasses a wide range of equipment, including automated assembly lines, robotic workcells, packaging machines, and material handling systems. Each machine is meticulously designed and optimized for its intended purpose. These machines are characterized by their versatility, precision, and reliability. They are often equipped with advanced sensors, actuators, and control systems to ensure optimal performance and seamless integration into existing production lines.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Logistic centers often work with automated package systems. If the goods slip back and forth, they will not stop in the packaging and the entire carton may fall off the conveyor belt. The solution: air cushion! They ensure reliable stablity.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

All EXCOR VALENO Flat Film can be used in automated packaging processes. Made from polyethylene, it has a wide range of applications, for instance as interleaving sheets and for wrapping and lining purposes. The EXCOR VCI substance is integrated into the polymer matrix. The anti-corrosion effect is long-term and active over large areas.

Request for a quote

BASIS, LLC

Ukraine

Basis50 - automatic step-by-step action machine with horizontal loading. Basis50 demonstrates stable performance and high quality packs at speeds with capacity up to 50 packs / min. Eastern sweets belong to the confectionery of the national assortment of the east people. Most often, similar laksta can be seen on the shelves of stores in cardboard boxes. The horizontal cartoner of the company "BASIS" will easily automate the packaging process and ensure high quality packs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

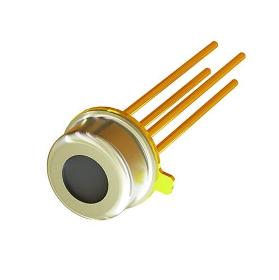

MICRO-HYBRID ELECTRONIC GMBH

Germany

The MEMS-based MTS1TEMP56 detects infrared radiation for non-contact temperature measurement. The 56 silicon thermopiles absorb the incoming radiated energy. The integrated mass absorber ensures the efficient conversion of the radiated energy into thermal energy. The thermocouples convert this thermal energy into electrical energy, which is output as a measurement signal. The single channel thermopile is the best choice for mass applications with quantities above 50000 pieces per year in medical and life science applications or in building automation. The TO46 package with small dimensions makes this component especially suitable for mobile devices. With a detectivity up to 0.67 *10^8 cm√Hz/W as well as a sensitivity up to 31 V/W, the materials offer reliable measurement results at a very good price/performance ratio. Nitrogen was used as backfill gas and a filter with a transmission cut on 5.5 µm. ATTENTION: 1 piece packaging unit contains 200 detectors each!

Request for a quote

BASIS, LLC

Ukraine

"Basis11 is an optimal and versatile model for packing bulk products in a Stabilo Bag package with a speed of up to 50 packs / min. With it, one can pack any small-piece and free-flowing product in bags such as a pillow, a stable bag, a Stabilo bag, and with the help of options, you can integrate bag re-closing systems into bags. Seed is a free-flowing snack product, which is popular in the CIS countries. Specialists of the company ""BASIS"" are working for many years with the largest manufacturers of this product and understand the features of the production process. The equipment of the company ""BASIS"" allows you to automate the process of packaging and provide: the ideal form of the package (pillow, gasset, stable package or Stabilo bag); consistently high line capacity; extension of the shelf life of seeds; weight accuracy; reliability and safety of the equipment for many years; ease of changeover and maintenance."

Request for a quote

BASIS, LLC

Ukraine

Basis11 is an optimal and versatile model for packing bulk products in a Stabilo Bag package with a speed of up to 50 packs / min. With it, one can pack any small-piece and free-flowing product in bags such as a pillow, a stable bag, a Stabilo bag, and with the help of options, you can integrate bag re-closing systems into bags. Breakfast cereals are completely ready-to-eat foods made from grains of corn, wheat and rice. Traditionally, flakes are packaged in a Stable Polymer Bag or a pillow bag, which is then placed in a carton box. The developed solutions of the company "BASIS" allow you to fully automate the process of packaging breakfast cereals and ensure optimal performance.

Request for a quote

BASIS, LLC

Ukraine

Basis 18 is our most technologically advanced and functional model for packaging bulk products in a Stabilo Bag package. Breakfast cereals are completely ready-to-eat foods made from grains of corn, wheat and rice. Traditionally, flakes are packaged in a Stable Polymer Bag or a pillow bag, which is then placed in a carton box. The developed solutions of the company "BASIS" allow you to fully automate the process of packaging breakfast cereals and ensure optimal performance.

Request for a quote

BASIS, LLC

Ukraine

"Basis 18 is our most technologically advanced and functional model for packaging bulk products in a Stabilo Bag package. Seed is a free-flowing snack product, which is popular in the CIS countries. Specialists of the company ""BASIS"" are working for many years with the largest manufacturers of this product and understand the features of the production process. The equipment of the company ""BASIS"" allows you to automate the process of packaging and provide: the ideal form of the package (pillow, gasset, stable package or Stabilo bag); consistently high line capacity; extension of the shelf life of seeds; weight accuracy; reliability and safety of the equipment for many years; ease of changeover and maintenance."

Request for a quote

BASIS, LLC

Ukraine

Basis 17 is the fastest model for packing bulk products in a “Pillow” bag. The machine has a step by step principle of action and reaches a speed of up to 120 packs / min. Breakfast cereals are completely ready-to-eat foods made from grains of corn, wheat and rice. Traditionally, flakes are packaged in a Stable Polymer Bag or a pillow bag, which is then placed in a carton box. The developed solutions of the company "BASIS" allow you to fully automate the process of packaging breakfast cereals and ensure optimal performance.

Request for a quote

BASIS, LLC

Ukraine

"Basis 17 is the fastest model for packing bulk products in a “Pillow” bag. The machine has a step by step principle of action and reaches a speed of up to 120 packs / min. Seed is a free-flowing snack product, which is popular in the CIS countries. Specialists of the company ""BASIS"" are working for many years with the largest manufacturers of this product and understand the features of the production process. The equipment of the company ""BASIS"" allows you to automate the process of packaging and provide: the ideal form of the package (pillow, gasset, stable package or Stabilo bag); consistently high line capacity; extension of the shelf life of seeds; weight accuracy; reliability and safety of the equipment for many years; ease of changeover and maintenance."

Request for a quote

BASIS, LLC

Ukraine

Basis80 is the most suitable cartoner model with capacity of 50-80 packs per minute. It ensures stable operation at the speed of up to 80 packs/min and high packages quality even from waste cardboard. Breakfast cereals are completely ready-to-eat foods made from grains of corn, wheat and rice. Traditionally, flakes are packaged in a Stable Polymer Bag or a pillow bag, which is then placed in a carton box. The developed solutions of the company "BASIS" allow you to fully automate the process of packaging breakfast cereals and ensure optimal performance.

Request for a quote

VERKOOIJEN VEEM

Belgium

We bag your granules, regrind, and powders (in, say, 25-kg bags) using two fully automated packaging lines. We use an FFS machine to fill them, followed by a palletiser and a shrink-sleeve machine for each line. If you so desire, we will print a lot number, date, manufacturer, or whatever information you’d like onto the bags, so that your goods remain easily traceable. We can also sample your product during the filling process for quality control in our lab. It doesn’t matter how you deliver your goods to us: from a silo, in bulk, in big bags, octabins, boxes, or bags. Would you like to use your own house style on the packaging? Customised stickers or labels? No problem: you ask, Verkooijen delivers!

Request for a quote

BRILLOPAK

United Kingdom

An optimised semi-automatic packing machine that puts you back in control of pack line speed. Reduced Labour Cost - Semi Automatic Packing Machine Increased product throughput Minimised quality issues FEATURES & BENEFITS: -Increases line speed, semi automatic packing machine. -Ergonomically designed for optimal performance. -Handles crates or cardboard trays. -Minimises health risks associated with repetitive working. -Tray infeed at rear or system minimises clutter along the line. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK P160 Unipick provides high-speed, accurate but gentle packing of tray seal, flow wrap and VFFS products into trays, cases and boxes. Ideal for packing fruit and meat. Multiple products Multiple patterns Delicate product placement FEATURES & BENEFITS: -Flexibility of operation. Single pick means one system can support multiple product types with multiple patterns. -Extreme accuracy of placement into crate ensures first class presentation on supermarket shelf. -Delicate handling: Due to single pick, individual products are placed gently and accurately into position meaning no damage to product or packaging. -No complex collation requirement: Less to go wrong. -Simple to operate, manage and maintain. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK C111 robotic packaging system provides high-speed packing of products into crates and cases. Due to the vertical movement of the robotic arm, the case packing system is able to pack to a depth of 800mm providing the versatility to pack to multiple container types. Ideal for case packing, tray packing and seal punnets. Over 150 packs per minute Precise product placement Multiple products and layer patterns FEATURES & BENEFITS: -High speed case packer: Up to 150 packs a minute. Multiple products with no tooling changeover. -Delicate handling: Using soft flexible grippers or vacuum cups with independent vacuum generators, no damage to product in pick process at high speed. -Very small footprint. -Can pack products up to 5kg weight. -Simple to operate, manage and maintain. ** Click for more **

Request for a quoteResults for

Automated packaging - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Food industry packaging machinery (10)

- Packing and packaging - machinery and equipment (6)

- Palletising machinery (3)

- Bags, plastic (2)

- Cartoning machinery (2)

- Anti-corrosion products, chemical (1)

- Automation - systems and equipment (1)

- Beverage industry - machinery and equipment (1)

- Coil Springs (1)

- Films and sheets, plastic (1)

- Films for packaging (1)

- Food Processing (1)

- Heat detectors (1)

- Internal transport systems (1)

- Machine tools - metal machining (1)

- Production and operational inspection (1)

- Sensors (1)

- Wood veneer - machinery and equipment (1)