- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automated packaging systems

Results for

Automated packaging systems - Import export

BRILLOPAK

United Kingdom

The BRILLOPAK C111 robotic packaging system provides high-speed packing of products into crates and cases. Due to the vertical movement of the robotic arm, the case packing system is able to pack to a depth of 800mm providing the versatility to pack to multiple container types. Ideal for case packing, tray packing and seal punnets. Over 150 packs per minute Precise product placement Multiple products and layer patterns FEATURES & BENEFITS: -High speed case packer: Up to 150 packs a minute. Multiple products with no tooling changeover. -Delicate handling: Using soft flexible grippers or vacuum cups with independent vacuum generators, no damage to product in pick process at high speed. -Very small footprint. -Can pack products up to 5kg weight. -Simple to operate, manage and maintain. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

An optimised semi-automatic packing machine that puts you back in control of pack line speed. Reduced Labour Cost - Semi Automatic Packing Machine Increased product throughput Minimised quality issues FEATURES & BENEFITS: -Increases line speed, semi automatic packing machine. -Ergonomically designed for optimal performance. -Handles crates or cardboard trays. -Minimises health risks associated with repetitive working. -Tray infeed at rear or system minimises clutter along the line. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK P160 Unipick provides high-speed, accurate but gentle packing of tray seal, flow wrap and VFFS products into trays, cases and boxes. Ideal for packing fruit and meat. Multiple products Multiple patterns Delicate product placement FEATURES & BENEFITS: -Flexibility of operation. Single pick means one system can support multiple product types with multiple patterns. -Extreme accuracy of placement into crate ensures first class presentation on supermarket shelf. -Delicate handling: Due to single pick, individual products are placed gently and accurately into position meaning no damage to product or packaging. -No complex collation requirement: Less to go wrong. -Simple to operate, manage and maintain. ** Click for more **

Request for a quote

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® 500™ bagging machine is a technologically-advanced, automatic filling and sealing machine designed for reliability, flexibility and optimising packaging throughput. Capable of cycling at rates over 100 bags per minute, this system was designed to maximise machine uptime while lowering total cost of ownership. State-of-the-art engineering has led to an innovative, inherently safe design. No light curtains or bulky guarding are required to achieve safe operation for hand load operations. This revolutionary new approach provides unobstructed access to the open bag, facilitating faster and more ergonomic loading. The system features a simple design with very few moving parts, reducing lifetime cost and improving uptime. Servo driven web controls along with job storage capabilities reduce the amount of bags in queue, eliminating waste and decreasing changeover time. ** Click for more **

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® AB 180™ bagging machine is capable of bagging at speeds up to 80 bags per minute. This automatic filling and sealing machine has been designed to be simple to use, quick to set-up and reliable. All features are designed for maximum uptime. The interactive AutoTouch™ control screen enables easy access to job storage, on-board system diagnostics and an operator help tool. User-friendly features and innovative components make this bagging machine one of the easiest to use bagging systems available. It can conveniently tie-in to a range of Autobag and third-party infeed bagging equipment. In addition, system-matched, polythene bags offer the most durable packaging solution to streamline the bagging operation. Genuine Autobag pre-opened bags-on-a-roll can be changed in less than two minutes to offer a fast, flexible and cost-effective bagging solution. ** Click for more **

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® PS 125 OneStep™ bagging machine is the ultimate in hand load packaging systems. This Print-n-Pack unit can efficiently print high resolution text, graphics and barcodes directly onto bags and present them for loading, bringing simplicity, versatility and value to low- to hand load applications. This compact bagging machine is ideal for mail order applications, short production runs and build-on-demand operations, offering bag sizes from 50 x 100 mm to 265 x 420 mm. The PS 125 OneStep bagging machine has a built-in PH 412 printer, eliminating the need for a separate labelling operation. The printer features a tilt-back print head for easy maintenance and the optional AutoLabel™ design software simplifies label creation. Pairing this bagging machine with system-matched Autobag polythene bags offers the ultimate solution for hand load applications. ** Click for more **

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag PS 125 bag sealing machine is the next step up from hand bagging, bringing speed and quality to hand load applications. It is ideal for low to mid-volume packaging operations due to its compact design and 'plug-and-play' configuration. Operating at speeds up to 25 bags per minute, it offers innovative engineering in a straightforward, tabletop design. The PS 125 bag sealing machine features a small footprint of 550 x 470mm and weighs just 37kg. The quiet, all-electric design does not require compressed air to run. The Autobag PS 125 bag sealing machine is simple to operate with a user-friendly display that enables easy access to operating parameters, job set-up, job storage and on-board system diagnostics. The unique, locking turntable links with the AutoThread™ feature to provide ergonomic handling and bag changeover. ** Click for more **

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® AB 255™ automated packaging machine is capable of packaging at speeds up to 55 bags per minute. This large bag packaging machine can efficiently pack and seal polythene bags up to 400mm wide by 660mm long. Applications include large parts, kits and catalogues. Package size can be changed in less than two minutes using durable Autobag pre-opened bags-on-a-roll. System features include an advanced AutoTouch™ control screen for easy job set-up and recall, modular E-box and valve packs, and powered unwind for maximum cycle speed. This automatic packaging machine can be integrated with a variety of Autobag and third party infeed systems. The Autobag AB 255 automated packaging machine is manufactured for reliability and productivity and offers a cost-effective way to package various large products. ** Click for more **

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Logistic centers often work with automated package systems. If the goods slip back and forth, they will not stop in the packaging and the entire carton may fall off the conveyor belt. The solution: air cushion! They ensure reliable stablity.

Request for a quote

SAGMAKSAN

Turkey

Automated Packaging Systems provides innovative bagging machinery, high-quality, system-matched bags, and exceptional customer service to some of the most demanding markets. We have helped customers streamline their packaging operations, improve productivity and lower their total cost of ownership by tailoring a packaging solution that’s perfect for their needs. From industries that require strict adherence to machine and material standards, such as aerospace and defense, food and pharmacy to industries that need eye-catching branded bag graphics like toys, cosmetics and pet products, we know the demands of your market and have a solution for virtually any bag packaging application.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The CLA low vibration XY table enables to perform movements on the X and Y axis through Ethernet commands. This equipment is ideal for micro plate analysis by camera. Specifications: - Micro plates dimension 130X90mm - Motion control in position by Ethernet protocol - Configurable motion speed and acceleration - Accurate and vibration-free positioning enables optimal reading - Optional vibration of micro plates in reading position to agitate the liquid

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

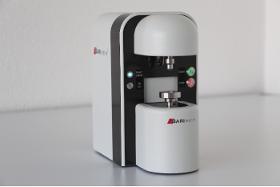

The EBATmètre® is a device for measuring height clearances. It is principally used to measure the moving parts of a mechanical watch movement.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

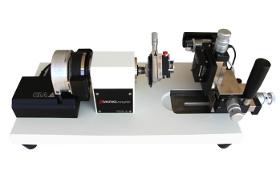

The NEOvario is a high-technology device, which is completely compact and integrated. The measuring devices will meet the demanding needs of torque and force measurement fields. ACCESSORYS : - Universal Digimes - Universal sample holder for watch movement - VARIOweight - Measurement standard - Adjustable angular support - Anti-vibration table

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

VARIOcouple® The VARIOcouple® apparatus for torque and force measurement manufactured by CLA is a very precise instrument mainly used in development laboratories of watchmakers. This instrument allows quantifying and analyzing small torques and forces generated in low stress systems. ACCESSORYS : - Universal Digimes - Universal sample holder for watch movement - VARIOweight - Measurement standard - CLApt1000 - Temperature sensor - Adjustable angular support - Anti-vibration table

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automation with direct impact: BARImètre® Automat can absorb 150 barrels per measuring channel (4 channels max). Load your machine, press START and the Automat will do the rest.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The BARImeter® is a precision metrology device that offers a great flexibility in the measurement of microtechnical, horological and medical parts. In particular, it is possible to measure small friction torques in both directions of rotation as well as holding torques. Examples: - Barrel measurement - Friction-wheel measurement

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

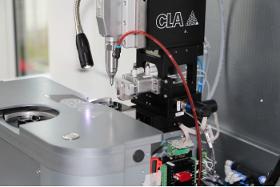

CLAremontage Automatic station which wind the movement by the rotor - Loading/unloading unit inserts - Independent station or integrated in an SMS line - Multi-calibers - Winding mechanical watches

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIKO GMBH

Germany

Measuring range 0 … 5000 mm (196.85 inches). Absolute measuring system. Pressure-resistant up to 350 bar, pressure peaks up to 650 bar. High degree of flexibility, adjustable to all measuring lengths thanks to teach-in. Redundant interfaces available. Safety version usable up to Perfomace Level d. Analog, CANopen, SAE J1939, CANopen Safety interfaces

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Ideal automation solutions for loading and unloading of parts on machining centres, presses, measuring stations, etc… Convenient, accurate, repeatable and reliable! The CLA Robot Cell is composed of the following: - A polyarticulated robot or scara with specific grippers - A camera device for part recognition - Automatic camera calibration - Parts loading/unloading system - Protection (cage, mats, detection, etc) - Each application is studied and simulated in order to define the ideal solution - Microplates screening. CLA is a center of expertise of Mitsubishi robots

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

To meet the growing and increasingly complex demand for machine vision systems, CLA has developed the CLAsight® solution. It is a package consisting of hardware (frame, camera, optics, lighting and industrial computer) and a versatile vision software application for positioning, aesthetic or dimensional inspection, time measurement by direct reading of hands, dial and date, and optical character recognition (OCR). Adapted to your needs, it will be the eye of your robot or the controller of your parts. Application example : - OCR Vision system - Reading of the hands of a movement or a watch - Aesthetic inspection - Positioning of microtechnical parts

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Manual winding station of watch movements - Control of the number of winding turns - Compact - Accurate - Silent - Ergonomic

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

- Standard shuttles 80x80 mm - RFID technology - SMS management by routing software OMS - Mainly used by watchmaking sector and microtechnology Exemples: - Assembly line for watch movements - Manual or automatic assembly line - Ergonomic assembly workstation - Manual assembly line

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

XYZ Positioning table - Maximum gripping surface - Reduced drive inertia - Ideal for handling, positioning and storing

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Translation-rotation unit - Adjustable speed - Simple and accurate positioning - Compact - Simple installation - Light

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Electric gripper with 4 fingers. - Power and speed control - Compact - Accurate - Silent Gripper PE410A is controlled. Hence it is also possible to control the opening position of the gripper.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automatic station for rate control of watch movements or watches without straps - Measure at 0 and 24h - Integrated 24h Storage - Possibility to add measuring devices - Power reserve control e.g. 72h - Using a robot - Multi-calibers

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The CLA multi-calibers chronometric Cell is used to monitor and tune the performance of a mechanical watch movement or a watch.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automation solution to perform medical sample analysis in diagnostic laboratories. Automatic sample distribution system transports the samples directly to the appropriate analysis system

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automatic screwdriver with torque measurement Compact station for workbench to ensure your assemblies screwed with high precision torque control. Main features : - Screws feeder by vibrating bowl - Preparation of the next screw in hidden time - Automatic screwdriver with integrated torque sensor - Preparation of the next part in hidden time thanks to the charging carousel - Removable precision tool to ensures a precise positioning and a multi-types parts management - User friendly interface allowing various screwing positions and configurations dedicated by type of parts - Ready to be integrate in assembly line

Request for a quoteResults for

Automated packaging systems - Import exportNumber of results

55 ProductsCompany type

Category

- Automation - systems and equipment (43)

- Packing and packaging - machinery and equipment (5)

- Food industry packaging machinery (3)

- Palletising machinery (3)

- Industrial robots (2)

- Pad printing (2)

- Assembly robots (1)

- Bags, plastic (1)

- Films for packaging (1)

- Software, technical and scientific (1)

- Storage equipment and systems (1)

- Warehouse logistics (1)