- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- anchorages

Results for

Anchorages - Import export

BOSSONG SPA

Italy

There are certainly technical and theoretical reasons determining whether an anchorage should be realized with resin or grout. However, in the practical application it is not so easy to define such limit, because of many factors, such as the compatibility with the original materials or simply feasibility problems during the execution. Significant parameters for choosing the type of anchors are type of substrate anchorage length hole diameter setting time and fixing mode waiting times for the loading of the anchorage The thixotropic consistency of the resin, that is useful to prevent from excessive spreading in the interstices of historical buildings, complicates the deep extrusion stage and limits the anchorage length in comparison with the application where the injection is realized with grouts.

Request for a quote

SEFINE TEKNIK MAKINE

Turkey

Fabrication Details Diameter : 12 mm – 120 m Dimension : According to the project specifications Standard : 8.8 and 10.9 quality with ST37 and ST42 material Areas of Application Civil Construction Steel Construcion Bridges Steel structure truss bars and y-branches

Request for a quote

BOSSONG SPA

Italy

Cooperation with the designer The characteristics of Bossong anchorages are defined on the base of the specific parameters of each single project, as well as the dimensions of the hole they must be embedded in, that depend on the type of material constituting the substrate. The change of information relating to the knowledge of the building’s state of preservation and of the aims of the provided interventions, drawings and pictures, the pattern of cracks and deformations, as well as the design of interventions, are very important to define the type of anchor that better fits the application and also to evaluate the intervention from the economic point of view. Tests in place The need to give to design engineers the possibility of an assessment of the behaviour of injected anchors in a particular application and in a specific setting has lead Bossong to equip its technician with a mobile instrumentation that allows the execution of onsite tests.

Request for a quote

ABS SAFETY GMBH

Germany

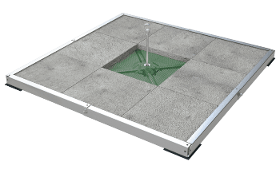

This cross-shaped anchor for flat roofs is weighed down using concrete slabs (50 x 50 x 5cm, not included). The design is based on a high-quality stainless steel frame (150 x 150 cm) with aluminium crossbars and a central, stainless steel anchorage point for one individual (Ø 16 mm). EN 795:2012, E For flat roof pitches ≤ 5° Weighed down using 8 concrete slabs (ca. 224 kg) Weight incl. ballast: ca. 245 kg; resulting roof load approx. 108.9 kg per m² Also designed for usage as an intermediate post in a lifeline system Incl. 5 EPDM patches to protect your roof membrane

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which comes with a base plate (150 x 150 mm), has been approved by the German Institute for Construction Technology ("DIBt"). It is installed on a steel structure and countered on the other side. The welded-on supporting tube (Ø 42 mm) easily withstands the pre-tensioning stress to which it is subjected when used in a lifeline system. Our standard package includes a set of installation materials. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Incl.stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Install the base plate (200 x 200 mm) of this stainless steel anchorage point (Ø 16 mm) on a load-bearing steel structure and then counter it using 4 stainless steel bolts. This anchor has been awarded national technical approval by the German Institute for Construction Technology ("DIBt"). The bolts and counter nuts required are included in the package. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 Incl. stainless steel installation set Upgrade with a supporting tube for usage as an end or corner support in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

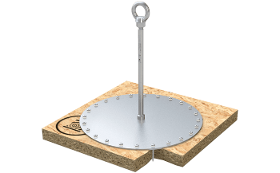

The round base plate (Ø 400 mm) of this stainless steel anchorage point (Ø 16 mm) guarantees that any force exerted on it is optimally distributed across a thin installation surface. Our standard package includes 24 stainless screws which are used to attach the device to an OSB / wooden surface. EN 795:2012, A + CEN/TS 16415:2013 OSB min. 12 mm Wood min. 18 mm Can also be installed on a vapour barrier or waterproofing (max. 15 mm) Optimal force distribution through the round base plate design Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

The two sides of this stainless steel anchorage point (Ø 16 mm) - specially designed for the roof apex - can be adjusted to the individual pitch of your roof using its adjustable base plate. Our standard package includes 8 stainless steel screws for attaching the device to the rafters. EN 795:2012, A + CEN/TS 16415:2017 Simply screwed onto the roof apex Suitable for usage on both sides of your roof Min. roof rafter dimensions: 80 mm x 120 mm Add a supporting tube for usage as an end or corner post in a lifeline system Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

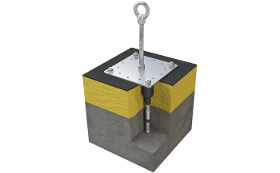

This stainless steel anchorage point (Ø 16 mm), which is cemented into concrete using special adhesive, does not cause any tension to arise in the subsurface and can be implemented in situations where the installation depth is a mere 50 mm. The anchor base plate (200 x 200 mm) is installed on an uncovered surface using the 4 anchor rods supplied. EN 795:2012, A + CEN/TS 16415:2013 Concrete ≥C20/25 Installation depth required: Only 50mm Recommended accessories: Special Adhesive WIT-VM-250 Add a supporting tube for usage as an end or corner post in a lifeline system Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

All you need to install this stainless steel anchorage point (Ø 16 mm), which is suitable for all directions of load, is an installation depth of at least 65 mm. The anchor base plate (200 x 200 mm) is fixed permanently to the concrete subsurface using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2013 Concrete ≥ C20/25 Installation depth required: Only 65mm Add a supporting tube for usage as an end or corner post in a lifeline system Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchor (M12 thread), which is screwed through a steel structure and countered on the other side, is equipped with an unobtrusive anchorage eyelet. It is designed to protect 1 individual from falling and is suitable for all directions of load (incl. axial). Our standard package also includes 1 counter nut. EN 795:2012, A Small and unobtrusive Designed for steel structures (countered) Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This mobile door traverse provides your workers with a temporary anchorage option in a fall danger zone at a minute's notice. This robust steel traverse is simply jammed in a door frame. The anchorage eyelet can be used to secure up to 2 individuals simultaneously (when equipped with corresponding PPE equipment). EN 795:2012, B CEN/TS 16415:2013 Simply jammed in a door frame Maximum door width: 1100 mm For 2 individuals (max. 900 mm)

Request for a quote

ABS SAFETY GMBH

Germany

The thread (M12) of this particularly robust stainless steel anchorage point is permanently installed in concrete using special adhesive. Once installed, it is suitable for all directions of load. You can install it on the ground, in a wall or overhead, depending on your individual needs. EN 795:2012, A Concrete ≥ C20/25 Recommended accessories: Special Adhesive WIT-VM-250

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) for steel surfaces is reinforced through a special supporting tube (Ø 42 mm). You can either use it as a single anchorage point or integrate it into a lifeline system. It is installed laterally using the angular plate supplied and then countered using 2 threaded bolts and corresponding nuts. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This reinforced, stainless steel anchorage point (Ø 16 mm) comes with a special supporting tube (Ø 42 mm) and includes an angular plate for lateral installation. Simply drill 2 holes through a load-bearing beam to install it. Our standard package includes threaded bolts and nuts for countering. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation Designed for load-bearing wooden structures Minimum beam dimensions: 100 mm x 200 mm Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) is attached laterally to a concrete surface. It is reinforced by screwing on the supporting tube supplied (Ø 42 mm) - making it ideal for usage as a stronge support in a lifeline system. Our standard package includes 2 anchor rods and an angular plate - all made of stainless steel material. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation Concrete ≥ C20/25 Recommended accessories: Special Adhesive WIT-VM-250 Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

The angular plate supplied with this stainless steel anchorage point (Ø 16 mm) makes light work of installing it on a steel structure. It can be attached to the structure permanently using the 2 threaded bolts included in the package. These are simply inserted through two pre-drilled bores and countered using the nuts supplied. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation 2-hole system for flexible installation Incl. stainless steel installation set

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ABS SAFETY GMBH

Germany

For a high load-bearing capacity in any direction, simply insert this stainless steel anchorage point (Ø 16 mm) through a pre-drilled hole in a wooden beam and counter it on the other side. This anchor is available with and without a protrusion and can be installed on the ground, laterally or overhead. EN 795:2012, A + EN CEN/TS 16415:2013 Protruding and non-protruding models available Designed for load-bearing wooden structures Minimum rafter dimensions: 100 mm x 120 mm Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

Depending on the subsurface (steel, copper, aluminium or titanium zinc), this stainless steel anchorage point can be installed on a metal roof using either aluminium or brass clamps. It is simply attached to a standing or copper standing seam using the specially-designed clamps supplied - completely penetration-free. EN 795:2012, A + CEN/TS 16415:2013 Freely-rotating anchor eyelet Clamped onto a seam without penetrating your roof surface Mounted on a single seam For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; titanium zinc and aluminium ≥ 0.7 mm For Rheinzink and similar systems Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

Simply clamp this freely-rotating stainless steel anchorage point onto a rounded-edge seam without penetrating your roof surface. As it is only attached to one single seam, you can work with it irregardless of the seam distance. The standard package includes specially-designed aluminium clamps which you can install without having to penetrate the roof membrane. EN 795:2012, A + CEN/TS 16415:2013 Completely penetration-free installation Mounted on a single seam Aluminium depth ≥ 0.8 mm For BEMO and similar systems Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point can be installed on standing seam roofs made of steel, copper, aluminium or titanium zinc without penetrating the roof surface. Depending on the subsurface, this kind-to-your-roof device is attached using the aluminium or brass clamps supplied in the package. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; aluminium & titanium zinc ≥ 0.7 mm For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

Attach this stainless steel anchorage point to the rounded-edge seams of a metal roof using the clamps included in the package - completely penetration-free. Your surface only needs to be 0.7mm thick (aluminium) to install it and protect 3 individuals from falls. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm Aluminium thickness ≥ 0.7 mm For BEMO and similar systems Incl. installation set We also supply a protruding model for use in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its special base plate, this stainless steel roof safety hook can be flexibly adjusted to fit the angle of your roof surface. The cranked shaft is designed to bridge the battens. It is installed by screwing the 2 stainless steel screws supplied through the counter lathing and into the beam below. Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Designed for load-bearing wooden structures Base plate allows flexible installation Simply screw it onto a wooden beam (also suitable for over-rafter insulation) Min. beam dimensions: 60 mm x 120 mm

Request for a quote

ABS SAFETY GMBH

Germany

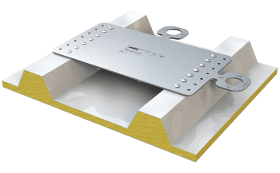

This anchorage device was specially-designed for flat roofs. It can be used as an anchor or system support and can be weighed down using concrete slabs (50 x 50 x 5 cm, not included) or gravel (not included). Its high-quality, stainless steel frame (150 x 150 cm) with aluminium crossbars is equipped with a central anchorage point (Ø 16 mm) - also made of stainless steel. EN 795:2012, E + CEN/TS 16415:2013 For flat roof pitches ≤ 5° Weighed down using 16 concrete slabs (ca. 448 kg) Weight incl. ballast: 483 kg | resulting roof load: approx. 214.7 kg per m² Anchorage point for 2 individuals Weighed down using gravel (ca. 450 kg) Weight incl. ballast: ca. 485 kg | resulting roof load: approx. 200 kg per m² Anchorage point for 1 individual (secures 2 individuals when used as an intermediate bracket in a lifeline system) Additional supporting tube required for usage as an end or corner post Incl. 5 EPDM patches to protect your roof membrane

Request for a quote

ABS SAFETY GMBH

Germany

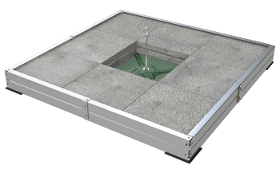

Whether this device is left standing out in the open or integrated into your roof greenery, our ABS Weight OnTop Max anchorage device for flat roof surfaces has been approved for installation without penetrating your roof surface - simply by weighting it down (50 x 50 x 5 cm, concrete slabs not included). Please observe the installation instructions provided in the "abZ" (national technical approval: Z-14.9-824) For flat roof pitches ≤ 5° Weighted down using 40 concrete slabs (ca. 1.120 kg) | resulting roof load approx. 61 kg per m² If implemented as an end or corner post in a lifeline system, a special supporting tube needs to be used

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm), which comes with a base plate (200 x 200 mm), is specially designed to avoid unintentional heat flux. Install this anchorage device in the concrete ceiling of a passive or energy-plus house using the 4 drive-in dowels provided. EN 795:2012, A + CEN/TS 16415:2017 Concrete ≥ C20/25 For roof structures ranging from 150 to 710 mm in depth Thermally insulated thanks to a special spacer Installed using 4x V4A expansion dowels (included)

Request for a quote

ABS SAFETY GMBH

Germany

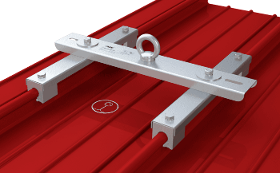

This extremely flat stainless steel anchor does not get in the way when stacking containers. Combine 2 ABS-Lock X-Flat devices to create a temporary lifeline system. The anchor is riveted onto the subsurface from above using 14 watertight blind rivets. The integrated sealant tape prevents water from seeping in. EN 795:2012, A + CEN/TS 16415:2017 Specially designed for sandwich and trapezoidal sheeting (positive/negative) For steel plating ≥ 0.5 mm Distance between the rows of pre-drilled holes: 180-250mm / 280-333 mm Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This anchorage point (Ø 16 mm) and its base plate (100 x 100 mm) are manufactured completely from stainless steel. The device is simply screwed permanently onto a wooden beam. It is available in different lengths and comes with the 4 stainless steel screws required for installation. EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Min. beam dimensions: 100 mm x 120 mm Incl. installation set Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Particularly robust stainless steel anchorage point with a screw-on supporting tube (Ø 42 mm), base plate (200 x 200 mm) and counter plate (100 x 100 mm). This anchor can be installed in a ceiling, on a facade, on a hollow profile or in lightweight concrete to secure 3 individuals. It can also be implemented as a trouble-free end support in a lifeline system. EN 795:2012, A + CEN/TS 16415:2013 Suitable for installation in a ceiling, on a hollow profile or in lightweight concrete Incl. stainless steel installation set Optional: Installation aid ABS-Lock X-DURCH Sleeve

Request for a quoteResults for

Anchorages - Import exportNumber of results

87 ProductsCompany type