- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminum alloys for die castings

Results for

Aluminum alloys for die castings - Import export

FRONTAL ALUMINIUM

Poland

manufactured according to currently applicable standards, such as: PN EN 1676; DIN 1725; PN-76/H-88027;ZN-86/MH-MN-260-14 , as well as according to the chemical composition specified by the customer, Each alloy is filtered and refined and can be modified at the customer's request.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: A356, A360, A380, ADC12 Process: Sand casting + machining Gravity casting + machining Die casting + machining Low pressure casting + machining Application: Air compressor Pumps Concrete plant equipment

Request for a quote

NORELEM FRANCE

France

Self-tapping threaded inserts for making high-strength, wear-free, vibration resistant screw connections in materials with low shear strength such as aluminium and aluminium alloys, brass, bronze, cast iron, duro and thermoplastics. The threaded inserts are tapered at the bottom and have a cutting slot. By screwing in they cut their own threads inside a receiver hole. This guarantees a completely secure and firm anchoring in the host material. Internal thread D1 acc. to ISO 6H. The threaded inserts with cutting slot spring slightly inwards in the slot region in some materials. This results in a screw locking effect. If this is not desired, we recommend the threaded inserts with a cutting bore.

Request for a quote

MAGMETT METALL INC.

Turkey

ntroducing ALSi, a remarkable aluminum-silicon alloy designed to cater to the needs of the casting industries. Crafted with utmost precision and expertise, ALSi offers unparalleled quality and performance. Our ALSi alloy is meticulously engineered to meet the stringent requirements of casting applications. With its exceptional properties, it ensures superior strength, durability, and impeccable casting results. Not only does ALSi excel in casting industries, but it also finds its utility in powder metallurgy. Its versatile nature allows for seamless integration into various manufacturing processes, expanding its range of applications. Experience the reliability and versatility of ALSi, as it revolutionizes the casting industry with its exceptional performance and unmatched quality. Trust in ALSi to elevate your casting projects to new heights of excellence.

Request for a quote

KIGEMA SP. Z.O.O

Poland

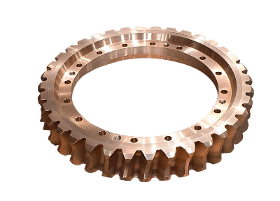

KIGEMA applies centrifugal casting to components using all copper and aluminum alloys covered by international and local casting standards (DIN EN 1982:1998-12, PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400), as well as using special alloys.

Request for a quote

KIGEMA SP. Z.O.O

Poland

KIGEMA applies centrifugal casting to produce bushes, rings and sleeves using all copper and aluminum alloys covered by international and local casting standards (DIN EN 1982:1998-12, PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400), as well as using special alloys.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality brass self-tapping ensat thread inserts. Particularly suitable for light metals and all types of plastics, both thermoplastics and thermosets This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

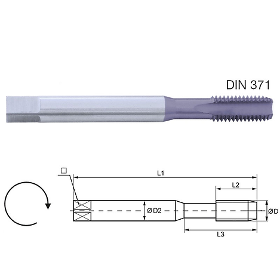

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Our high-performance cutting paste in the practical 100ml pack is characterised by particularly high pressure additives that achieve a very high lubrication performance. The paste adheres firmly to the cutting edges and only becomes liquid during use. For optimum results, the cutting paste should be applied undiluted. This cutting paste is ideal for many machining operations such as drilling, thread cutting, thread cutting, milling, core drilling and sawing. It is suitable for all types of steel - from iron and tool steel to high-alloy steels and chrome-nickel alloys to aluminium, titanium, manganese, cast steel, grey cast iron, brass, bronze and all stainless steels V2A, V4A, INOX etc. Due to the environmentally friendly, petroleum-free, chlorine-free and sulphur-free formulation, the high-performance cutting paste not only offers longer tool life, but also leaves no greasy oil film on the workpieces.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANSEE SE

Austria

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

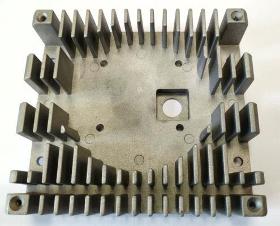

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

TURKOGLU

Turkey

Overground Fire Hydrant / Body, Lower and Upper Pipe: GG-25 Cast Iron / Coupling: Aluminium Alloy / Handwheel : GG-25 Cast Iron / Disc : GGG-40.3 Ductile Iron / Check Valve: Brass / Upper shaft : Stainless Steel / Shaft motion pipe: Galvanized steel or Stainless Steel ** Application area: Fire installations

Request for a quote

GUANGZHOU OURS BUILDING MATERIALS CO., LTD

China

The aluminum alloy handrailing is made of high-quality aluminum alloy special-shaped pipes. Instead of the traditional angle aluminum connection, the overall welding technology and overall plastic spraying process are adopted. The strength is reliable, the appearance is high-grade, and the quality is superior. In particular, the aluminum alloy handrailing can be matched with various cast aluminum decorations to transform a rich and colorful composition, highlight the unity of practicality and artistry, and meet people's pursuit of beauty.

Request for a quote

MODULUS METAL

Turkey

Milling Drilling Turning / Boring / Parting Reaming Broaching Planning, Shaping, Slotting

Request for a quote

MODULUS METAL

Turkey

Modulus Metal has ISO / IATF certified die casting supplier base, mainly in aluminum high pressure die casting, and our partner suppliers are experienced in automotive, aerospace, agricultural and industrial machinery manufacturing for many years. Production capabilities: Up to 10 kg /piece Quantity: Mainly high volumes of production due to tooling cost Aluminum,As Cast,Wrought,COPPER,Aluminum Bronze, Brass, Bronze, Coated Copper, Copper-Nickel, Silicon Bronze,ZINC,Aluminum Alloy : Forming Die Alloy, General Casting Alloy, Pressure Die Casting Alloy, Slush Casting Alloy, Wrought,Commercial Purity,Copper Alloy : Pressure Die Casting Alloy , Wrought

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Aluminium alloys • Aluminium bronzes • Copper alloys • Sand cast aluminium and cast magnesium • Graphite

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

ALUTIL MOP 417 is an non-pigmented dressing of petroleum, based on mineral oils. It is applicable for die-castings zinc and aluminum alloys.

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

EXO – COATING ZG 3V is an alcohol -based dressing. Its characteristic is a high refractoriness and a wide range of applications. Purpose of use: Aluminium and aluminum alloys, Steel castings, Nodular graphite cast irons, grey cast irons, other colored materials

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

POPEX is an adhesive for cold sticking of sand cores and moulds. It is a paste of bright brown color. Used in Aluminium and aluminum alloys, Steel castings, Nodular graphite cast irons, Grey cast irons, Other colored materials,

Request for a quote

EXOTERM-IT D.O.O.

Slovenia

AQUADUR M-15 is a water-based ceramic dressing in pasty form. Its characteristic is a high refractoriness. Approximate composition: about 60 % refractory filling (Al and Mg silicates, Fe oxide) about 6 % organic binder about 34 % water Purpose of use: Aluminium and aluminum alloys, Steel castings ,Nodular graphite cast irons, Grey cast irons, Other colored materials

Request for a quoteResults for

Aluminum alloys for die castings - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Tools & Hardware (11)

- Aluminium and aluminium alloys (5)

- Aluminium alloys (4)

- Casting, steel (3)

- Iron, steel and metallurgy - import-export (3)

- Die casting moulds (2)

- Foundries - copper, bronze and brass (2)

- Fire alarms and detection - equipment and systems (1)

- Foundries, aluminium (1)

- Hand tools, non-power (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Nuts and bolts (1)

- Stairs and handrails (1)

- Steels and metals - forming and cutting (1)

- Steels and metals - welding and brazing (1)

- Surface treatment - machinery and equipment (1)