- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- alloy and copper rods

Results for

Alloy and copper rods - Import export

ANKARA BRONZ

Turkey

ECU 99,9 % : Electrolytic is used as copper material with a conductivity of 58, electrode in erosion, high-low current panel and busbar in substations. Among our standard products: Rod, Sheet Plate, Straight pipe, Tube Coil, Box profile, Grounding rod - plate, Roofing, Copper fittings and thin wires. Also, sheet plate measurements which do not have a standard are brought to necessary measurement by forging at desired dimensions. Parts that require CU-Cr-Zr (Chromium alloy) High electricity conductivity, hardness and strength at high temperatures: Are used as point welding electrode and seam welding disc at the source of low carbon steels (Panel radiator, Gasoline warehouse, etc.) and Galvanized steel plate (Automotive and white goods), electrode holder at spot welding machines, plunger electrode at erosion machines and contact busbar at substations.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

We offer a wide range of rods, which are used for electroplating, switchgear, ship building and power generating equipment, as they are high-conductivity. On the other hand, they are widely used as radiator in electrical product, as its high- thermal conduction. They are produced that copper fluid is casting to the billet moulds and follows to the extrusion press, after that annealed rods are drawn, to be copper rods, 2000 mm to 6000 mm length, 10 mm to 175 mm diameter and they are according with TSE 435, DIN EN 12163 and DIN EN 13601. General properties material with minimum copper content 99.95%

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Beside Our exsisting wide range, we also develop profiles as per customers requirments.They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380. They are used in following main applications: Automobiles and railways Wide range of uses in electrical industry, e.g. switchgears, earthing rods etc. Transformers and circuit breaker terminals Electrical holders and clamps Defence industries etc.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

We offer a wide range of rods, which are used for electroplating, switchgear, ship building and power generating equipment, as they are high-conductivity. On the other hand, they are widely used as radiator in electrical product, as its high- thermal conduction. They are produced that copper upward casting and follows to the Continuous press, after rods are drawn, to be copper rods, 1000 mm to 6000 mm length, 10 mm to 90mm diameter and they are according with TSE 435, DIN EN 12163 and DIN EN 13601. General properties material with minimum copper content 99.95%

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

We offer a wide range of rods, which are used for electroplating, switchgear, ship building and power generating equipment, as they are high-conductivity. On the other hand, they are widely used as radiator in electrical product, as its high- thermal conduction. They are produced that copper fluid is casting to the billet moulds and follows to the extrusion press, after that annealed rods are drawn, to be copper rods, 2000 mm to 6000 mm length, 10 mm to 175 mm diameter and they are according with TSE 435, DIN EN 12163 and DIN EN 13601. General properties material with minimum copper content 99.95%

Request for a quote

JINTIAN COPPER

Germany

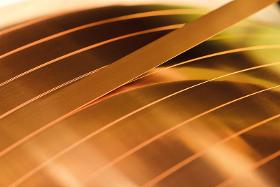

Main products: TMY copper, T2 / TU2 copper rods, profiled bars, electrical round copper billets Product characteristics: High copper content, low oxygen content, compact structure, uniformity, low electrical resistivity, high electrical conductivity, precise size, excellent mechanical properties; can be customized according to demand Applications: High and low voltage electrical appliances, power electronics, power transmission and transformation, automotive industry, molds, communication technology, cables, machining, metallurgical chemicals, construction industry Production capacity: 100,000 tons Honorary titles: Zhejiang Famous Brand Product

Request for a quote

JINTIAN COPPER

Germany

Main products: Hpb59-1、Hpb58-2A、C3604、C3771、C37700、C36000、C46500、C46400、CZ132、CW602N、Grade A polished copper ingots Product characteristics: Excellent mechanical properties, excellent hot workability, good machinability, excellent resistance to stress corrosion. Applications: Valves, pipe fittings, water heating and sanitary ware, air conditioning components and other hardware Production capacity: 207,000 tons Honorary titles: China's Top 10 Copper Wire & Rod Company, Zhejiang Famous Brand Product, Ningbo Model Unit Manufacturing Enterprise

Request for a quote

JINTIAN COPPER

Germany

Main products: Leaded brass, brass, lead-free free-cutting brass, copper, tin bronze, chrome-zirconium copper Product characteristics: High electrical conductivity, thermal conductivity, good strength and hardness, heat resistant, wear resistant and deformation resistant Applications: Aerospace, automobile manufacturing, communication technology, precision processing, household appliances, hardware, welding materials Production capacity: 207,000 tons Honorary titles: China's Top 10 Copper Wire & Rod Company, Zhejiang Famous Brand Product

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

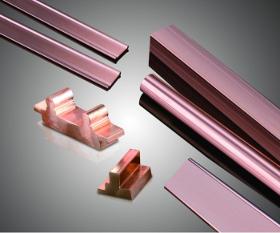

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Connectors, relays, springs, high voltage contacts

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Basic material for electrical parts.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

Good compromise between alloy properties, lower metall cost and better scrap value assessment conditions. It has very good cold forming properties and a good conductivity combined with high strength and hardness.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Pancake coiled copper tube which is named for its coiled style, is widely used on the connecting for the separated air-condition. On the other hand it is used in water distribution systems, chilled water mains, drainage and vent systems, heating systems (includingsolar), fuel-oil systems, oxygen systems also in non-flammable medical-gas systems. They are produced that Copper fluid is casting to the billet moulds and follows to the extrusion press, after annealed tubes are drawing, to be copper tubes. They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper or aluminum, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc.

Request for a quote

SHAKUNT ENTREPRISES PVT LTD

India

Copper coated low alloy solid wire Uniform coper coating The weld deposits are notch free with excellent mechanical strength Typical 1.25Cr0.5Mo weld deposit Radiographic weld quality

Request for a quote

SHAKUNT ENTREPRISES PVT LTD

India

Copper coated low alloy wire Smooth wire feeding and arc stability Increase in strength at elevated temperature High resistant to cold cracking Radiographic weld quality

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in development and production of technical high performance alloys components : copper alloys, nickel alloys, but also aluminium alloys, specialty steels, stainless steels, titanium and nickel supperalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries.

Request for a quote

EMTA KABLO SAN. VE TIC. AS

Turkey

EMTA Conductor & Cable has worldwide experience in rod manufacturing for different standarts and countries. EMTA has produced in excess of 60,000 metric tons of Continuous Cast Aluminum Rod in its own plants in Kadirli. EMTA Aluminum Continuous Casting and Rolling lines are designed to produce pure electrical conductor grade aluminum rod by using A7E (purity of 99,7%) and A8 (purity of 99,8%) and alloy conductor grade aluminum rod coils directly from pure molten metal on a continuous basis. EMTA can produce heat-treatable alloys rod with tempers supplied which from F (as Fabricated) to T4 (Thermally Treated). EMTA manufacturing lines are designed to produce from 9.5 to 15 mm diameter rods in level wound coils and packed in both "Eye to Side" and "Eye to Sky" coils of 2 tons covered with paperboard and plastic shrinkage to be delivered on wooden pallets.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our highly specialized Spinodal materials are custom-engineered for electronic connectors and deliver major advantages in comparison to traditional materials such as Beryllium Copper (BeCu). We offer precision strip and wire products in alloy Pfinodal® (UNS C72900), a copper nickel tin Spinodal alloy, for the manufacturing of high performance electronic connectors in the electronics industry. Safe Alternative to Beryllium Copper (BeCu) Beryllium Copper (BeCu) materials are the historical choice for electronic connectors. Our high performance Pfinodal® (UNS C72900) delivers similar mechanical properties to Beryllium Copper but without the harmful exposure risks.

Request for a quoteResults for

Alloy and copper rods - Import exportNumber of results

33 ProductsCompany type