- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air suction

Results for

Air suction - Import export

YALCIN GROUP

Turkey

DETAILS General Features: We provide ventilation with our own production snail fans using polypropylene material . Technical Specifications: Areas of Use:

Request for a quote

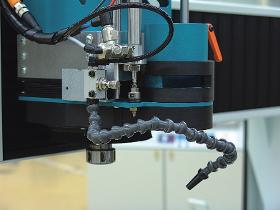

MECANUMERIC

France

System allowing to direct a compressed air jet to the tool. Subject to the machine configuration / chosen options. Online sales on Meca-line site here

Request for a quote

FERPLAST SNC

Italy

Special sealers ME 455/605 VAD with air suction system (max 80%) suitable for volume reduction and better preservation of products. The machine is equipped with a double sealing bar with a sealing width of 5 mm, an electric pedal drive and pneumatic cylinders, mobile nozzles for air intake, an adjustable timer for suction, sealing and cooling. The ME 4510/6010 VAG model with a ATM gas injection system is also available. This variant is equipped with a double sealing bar with a 10 mm sealing width, electric pedal drive, mobile nozzles for air intake and gas injection, adjustable timers for suction, intake, sealing and cooling.

Request for a quote

SFA ENVIRO

France

Submersible degreasing aerator The AEROSPEED is a submersible degreasing aerator that produces microbubbles which in turn causes grease to float onto the liquid surface. The unit is easy and simple to operate and install. Robust IP68 cast iron motor, coated with epoxy and equipped with a temperature control sensor Motor specially adapted to the constraints of operating a submerged degreasing aerator according to Europelec standards Stainless steel suction tube Stainless steel frame specially designed to optimize the hydraulic flow Stainless steel propeller specifically designed to ensure simultaneous mixing and suction of air.

Request for a quote

PARSMEGA MAKINA

Turkey

The air purifies the flour dust mixture from flour dust, traps the flour dust and ensures that clean air is expelled from the chimney. Flour dust captured by specially woven bags returns to the system. Thus, flour loss is prevented. The filter section body is made of 2-6 mm sheet metal and the lower part is a cast iron plate. The transmission and engine parts are located on the cast plate. The gearmotor is mounted on the transmission as a battery. The transmission located in the filter section drives the steel plate arm also located in this section. There is an air suction cup on this steel arm. This air suction cup closes the filter bags on its upper part and located in the pipe section, one by one, at regular intervals (with the help of the transmission movement arm) and sucks the product inside. Meanwhile, the clean air included with the product

Request for a quote

PARSMEGA MAKINA

Turkey

Aspirators have high air suction power and are manufactured in different sizes and engine powers. Aspirators with different capacities; It is frequently used in the aspiration of cleaning machines in Flour Factories. This type of aspirators are also used for the aspiration of low capacity semolina purifiers. They operate at a flow rate of approximately 300 m3/hour. They are generally used in small capacity cleaning units.

Request for a quote

PARSMEGA MAKINA

Turkey

It enables the broken and crushed product in the rollers to be transported to the sieve and other machines. It absorbs the broken or crushed product through steel pipes and distributes it to cyclones and ecluses. Consists of outer body and fan part. The outer body has a snail structure. The internal fan is designed with paddles according to capacity. It is mounted coupled to the engine located on the outer body. The fan inside the body rotates at high speed and provides air suction and pressure. Since the fan is specially balanced, it does not cause vibration or noise. In addition, since the outer body is placed on the main chassis on special rubber wedges, it does not cause vibration on the chassis.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic ionized air rinser/bottle cleaning machine is mainly used for clean the inside of the container , both for glass and plastic bottles, usging the pure filted ionized air and sunction the dust to ensure the containers are cleaning. This bottle air rinsing machine is a linear types, multy heads from 2 nozzles to 20 nozzles to meet the capacity demand, the diving nozzles driven by servo motor, and if choose the turn up types for cleaning, the turning arm will be also driven by a servo motor. The machine is universal for glass bottle and plastic bottle rinsing with air.. It blows inside of bottle with clean air and sucking the dust out of the bottle. The working principle is: when the bottle into the conveyor, the compressed air will be discharged high pressure air to clean the container, when blowing air meanwhile will suction the dust.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

At IFA Technology we use all types of pumps available on the market for conveying liquids. We consider all necessary requirements for the safe and reliable conveyance of your products. Solids can be conveyed mechanically, pneumatically and hydraulically. For mechanical conveying, screws, conveyor belts, elevators, vibratory troughs or tube chain conveyors are used. Pneumatic conveying is mainly applied in the chemical and pharmaceutical industries as well as for conveying granulates in plastics processing and the food industry. The pneumatic conveyance process is carried out by suction and compressed air, i.e. by vacuum or positive pressure, and is mainly used when sensitive substances are transported. Heavy substances such as cement, sand or gravel are mainly transported by positive pressure.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The machine is universal for glass bottle and plastic bottle rinsing with air.. It blows inside of bottle with clean air and sucking the dust out of the bottle. Under more than 5 years of manufacturing experience ,the air rinser with development and production with a new generation of bottle washing machine equipment, scientific and reasonable equipment adopts PLC and touch screen control, simple operation, convenient maintenance, stable and reliable performance; The working principle is: when the bottle into the conveyor, the compressed air will be discharged high pressure air to clean the container, when blowing air meanwhile will suction the dust. Main features: 1. Specially design for bottle and jar rinsing with ionized air before filling, it combined ionized air flushing with UV sterilizing. 2.The whole washing machine is a full automatic system, PLC control, 7 inch touch screen operator, Simens, Schneider, Airtac, Omron world famous electric and pneumatic components.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

Using negative air pressure, the Dry Destoner makes the wheat flow on an air cloud. The heavier foreign materials (stones, glass etc.) stay on the vibrating sieve. The sieve acts as an escalator and carries the product to the discharge spout. The machine is driven by two vibration motors. The vibrating body is isolated from the chassis using rubber vibration dampeners and the vibration is isolated. The inclination and air suction level are adjusted for proper cleaning.

Request for a quote

AYTAV POULTRY EQUIPMENT

Turkey

>> Dimensions 137.5 x 137.5 cm >> Blades Stainless Steel >> Motor Power 1.1 kw >> Body Galvanized >> Back Shutter >> Air Flow 42000 m³ >> Cfm 24720 The ideal solution for house ventilation with its high capacity and high air suction power. Specially designed, air grooved, high air draft capacity. Energy saving thanks to specially designed propeller. Propellers can be produced in stainless steel and galvanized upon request.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray nozzles for detergent spraying. Generates large amounts of foam, air suction is driven only by liquid pressure. No compressor is necessary. Cleaning effect is improved due to the long residence time of the foam. *Spray angle of 80° – 100° is for reference only, measured when spraying 100 times diluted commercial dishwasher detergent. Applications Washing outer surface of vehicles Cleaning of conveyors in food industry

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Device for automatically blowing the adhering water off after passing through the pretreatment plant. The rotary blow-off zone is a device for blowing the adhesive water off workpieces that have been washed for the purposes of painting. It consists of a closed stainless steel sheet metal housing with forced ventilation and is employed immediately after the washing installation. In order to achieve more effective drying in the case of fissured surfaces, the blower nozzles are arranged on a rotary axis. The adhering water is blown off by the parts by air blown at high speed through the rotary blower nozzles. The effect of this is that no water droplets remain on the workpiece that could lead to slight marks in the paint film. Due to the varying blowing direction, the water is also blown out of problem zones and scooped parts in most cases. In order to be able to optimise the direction of the blower nozzle air jets, the nozzles have adjustable nozzle heads. The water that is blown off runs back into the pretreatment plant. The blowing air is extracted from the blowing tunnel via a return air duct with adjustable suction apertures.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 2 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 2-stage dedusting system. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. The separated dust content is sucked out into an external collection bin. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 3 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 3-stage dedusting system with ionisized air. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Dedusting capacity up to 25 kg/h. Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAMA AERNOVA SRL

Italy

Model with pallet swap Data sheet The cutting shuttle table used to support the metal sheet must be integrated into the laser and plasma cutting machine. It is equipped with a drive system that follows the laser head to focus the suction of fumes and dust in the sectors affected by the cut. Its installation ensures the quality of the production environment and the protection of those who work there. Benefits This model with automatic pallet swap is composed of two sliding pallets driven by a chain drive, a hydraulically driven external lifting unit that allows vertical pallet change from a air suction segment table with trimming collection drawers which can be extracted from the side. The laser cutting downdraft table is interfaced with automatic load/unload cells and it is composed of pre-assembled modules, easy and quick to install. Standard equipment tanks with suction segments plate support grid leveling feet position sensors

Request for a quote

SEMTES MUHENDISLIK IC VE DIS TIC.LTD.STI.

Turkey

The RS burners series covers a firing range from 44 to 2290 kW, and it has been designed for use in low or medium temperature hot water boilers, hot air or steam boilers, diathermic oil boilers. Operation is “two stage progressive”; the burners are fitted with a microprocessor-based burner safety control box which supplies indication of operation and diagnosis of fault cause. The elevated performance of the fans and combustion head, guarantee flexibility of use and excellent working at all firing rates. The exclusive design ensures reduced dimensions, simple use and maintenance. Optimisation of sound emissions is guaranteed by the special design of the air suction circuit and by incorporated sound proofing material. A wide range of accessories guarantees elevated working flexibility.

Request for a quote

ESVANA

Turkey

Air accumulations which occur particularly in pump outlets when water is delivered to pump outlets and pipe lines and makes water flow area narrower and causes decrease in capacity. Double ball vacuum lifters are used for preventing this adverse issue and in locations where high efficiency is required. Air which occurs when water is delivered to system firstly fills into vacuum lifter and discharged through holes which are located at inner side covers. Then water fills into vacuum lifter and lifts ball up and holes are closed and sealing is maintained.

Request for a quoteResults for

Air suction - Import exportNumber of results

21 ProductsCompany type

Category

- Oils, cooking - machinery and equipment (3)

- Bottling and filling - machinery and equipment (2)

- Plastics - industrial machinery and equipment (2)

- Air conditioning, aeration and ventilation equipment (1)

- Bird cages and aviaries (1)

- Burners, industrial (1)

- Cabinets and cupboards (1)

- Flour milling - machinery and equipment (1)

- Gas extraction - systems and equipment (1)

- Goods handling systems, continuous (1)

- Nozzles - ferrous metal (1)

- Package sealing machinery (1)

- Treatment of industrial waste water (1)