- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d printing service

Results for

3d printing service - Import export

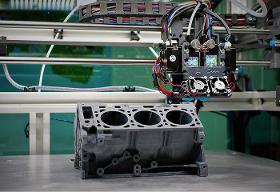

EWOQE GMBH & CO. KG

Germany

Discover the world of Additive Manufacturing with EWOQE! As a leading B2B partner at the pinnacle of industrial standards, we utilize 3D printing to revolutionize traditional manufacturing methods. Our focus is on producing components with precision and efficiency, not to replace existing production processes but to enhance them. We are convinced of the diverse possibilities that 3D printing offers and view it as an indispensable tool for achieving our goals. Through continuous investments in research and development, we remain at the cutting edge of this technology, always offering our clients innovative solutions. Our range of services includes the creation of 3D models, the manufacturing of prototypes and small series, as well as the production of final products. From high-quality plastic parts to design and model making, we are your reliable partner for all your Additive Manufacturing needs.

Request for a quote

PLÁSTICOS CLOSSA

Spain

Fully functional parts In partnership with an external company, we carry out a 3D printing service. In case of need, we can print fully functional pieces. Individual customization They can be used to validate a design, to test the assemblability or to use in production, if they are small lots. All this, in a very short time and with the possibility of customizing the parts individually.

Request for a quote

3D PROTOTIPAI

Lithuania

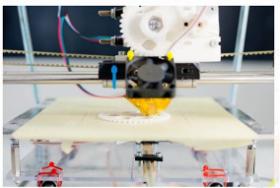

3D printing – New, innovative and promising production technology. It is the process by which digital 3D model is converted to real object, when product is built up layer by layer. 3D printing is not only a new way of materializing ideas, but also an excellent opportunity to check funcionality and ability of assembly of product before serial production. We work with the latest tecgnologies of 3D printing and we have many years of experience in engineering design. We are flexible and proffesional, so we can guarantee you effective and high quality production. Our goal is to find the best and most innovative solutions for your individual needs.

Request for a quote

PEEKCHINA CO., LTD.

China

Process 3D Printing Additive Manufacturing Feature Low MOQ, 1pc acceptable. Customized Make. Complex Tolerance & Shape. MATERIAL GRADE ARKPEEK-1000: 100% PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

unprecedented opportunities thanks to newest 3D-print technology: whether ultra-stable up to 103°C/217,4°F heat-resistant plastic parts or elastical silicone up to 65 shore – we can meet your very special needs on a wide range – with a print resolution of up to 15 μm! Realizing ideas quickly: we print your prototypes, devices, models, sales samples, artworks or even final products made of plastics or silicone. For your individual 3d-print, we need your data-model in STEP- or STL-format. We are looking forward to your inquiries!

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your specialist for high-precision plastic injection molded parts for medical technology! We understand the demanding requirements of your industry and deliver customized solutions that meet the highest quality standards. Our experienced team collaborates closely with you to develop the optimal plastic injection molded parts for your medical applications. Utilizing state-of-the-art technologies and high-quality materials, we ensure our products comply with the strictest regulatory requirements and offer the highest precision and reliability. Whether for components of medical devices, laboratory equipment, or consumables, we are your trustworthy partner for all your needs in plastic injection molded parts for medical technology. Rely on EWOQE for top-notch quality, rapid delivery times, and excellent customer service. Contact us today to learn more about our tailored solutions for medical technology and to advance your projects.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your reliable partner for the prototype construction of enclosures. Offering a wide range of 3D printing processes such as FDM, SLS, MJF, and SLA, we provide fast and cost-efficient solutions tailored to your requirements. Our experienced team is dedicated to supporting you in the design and manufacturing of enclosure prototypes, no matter their size or quantity. We understand the critical importance of quality and functionality for enclosures in the industry and deliver high-precision components that meet your specifications. Leveraging our additive manufacturing technologies, we can produce complex enclosures with high accuracy and attention to detail. Our express service enables us to swiftly handle even the most urgent projects, optimizing your time-to-market and ensuring your ventures progress efficiently. Trust EWOQE as your trusted partner for enclosure prototype construction.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your expert in Rapid Tooling, especially for prototype initial samples. Our comprehensive range of 3D printing processes, including FDM, SLS, MJF, and SLA, offers fast, cost-efficient, and high-quality solutions for your Rapid Tooling needs. Our experienced team is here to support you in the design and manufacturing of Rapid Tooling components, regardless of their size or quantity. We understand the urgency and requirements of the industry for high-quality prototypes and provide you with precisely manufactured components that meet your specifications. Thanks to our additive manufacturing technologies, we can reproduce complex geometries and fine details, helping you quickly obtain high-quality prototype initial samples. Our express service ensures rapid turnaround times to optimize your time-to-market and efficiently advance your projects.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the world of Rapid Prototyping with EWOQE! As a leading B2B partner at the highest industrial level, we use 3D printing to revolutionize traditional manufacturing methods. Our focus is on quickly and precisely manufacturing components, not to replace existing production processes but to complement them. With our deep understanding of the possibilities offered by 3D printing, we provide innovative solutions for complex geometries and customized designs. Through continuous investments in research and development, we remain at the forefront of this technology, always offering our clients top-notch services. Our range of services includes the creation of 3D models, the manufacturing of prototypes and small series, as well as the production of final products. From high-quality plastic parts to design and model making, we are your reliable partner for all your Rapid Prototyping needs.

Request for a quote

PRO DESIGN

Turkey

Personalize your prints with our high-quality custom digital printing.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your specialist for prototyping in the automotive industry. We offer a variety of 3D printing processes such as FDM, SLS, MJF and SLA to meet your requirements. Our dedicated team works quickly and cost-effectively to deliver high-quality plastic components in various sizes and quantities. With our expertise in additive prototyping, we support you in the design and manufacture of components for various applications in the automotive industry. Our focus is on providing you with fast and reliable solutions that meet your specific requirements. Whether you need small or large components, one-offs or series production, we have the build space and capacity to meet your requirements. With our express service, we can also handle urgent projects quickly to optimize your time-to-market.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your expert for prototype construction in precision mechanics! We offer a comprehensive range of services to meet your demanding requirements. Utilizing advanced 3D printing techniques such as FDM, SLS, MJF, and SLA, we deliver high-precision plastic components quickly and cost-efficiently. Our dedicated team is here to assist you with the design and manufacturing of prototypes, no matter their size or the quantity required. We understand the critical importance of quality and precision in precision mechanics and are committed to exceeding your expectations. Thanks to our additive manufacturing technologies, we can produce complex components with high accuracy, aiding you in efficiently achieving your development goals. Our express service also ensures fast turnaround times to optimize your time-to-market. Depend on EWOQE as your reliable partner for prototype construction in precision mechanics.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EWOQE GMBH & CO. KG

Germany

Discover EWOQE's comprehensive service offering in 3D printing for mechanical components and prototype construction! We provide a variety of advanced 3D printing techniques such as FDM, SLS, MJF, and SLA to meet your needs and produce high-precision components. Our experienced team assists in the development and manufacturing of prototypes as well as functional mechanical parts. Understanding the importance of quick iterations, we offer rapid turnaround times to shorten your development cycles and optimize your time-to-market. With our advanced 3D printing technologies, we can achieve complex geometries and fine details to ensure your components meet the highest quality standards. Whether you require prototypes for product development, individual pieces for specific applications, or series production, we have the solution for you. Depend on EWOQE as your trusted partner in 3D printing for mechanical components and prototype construction.

Request for a quote

EWOQE GMBH & CO. KG

Germany

At EWOQE, we offer top-tier services in model making for design, testing and development, as well as prototype construction through advanced 3D printing. Our highly skilled engineers assist you in designing and manufacturing prototypes that perfectly meet your requirements. Utilizing additive manufacturing technologies and high-quality plastics, we produce high-precision components quickly and cost-effectively. Our processes are designed to enable accelerated product development and optimize your time-to-market. Whether you need prototypes for new product designs, functional components for testing, or models for design purposes, we have the solution for you. Rely on our expertise in 3D printing and plastic processing to meet your requirements and successfully implement your projects.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE provides model making, prototype construction, and 3D printing services for the industry. Our team of experts is highly skilled in designing and producing high-precision plastic components using advanced additive manufacturing technologies. We strive to offer swift and cost-effective solutions for your development projects, utilizing our efficient approach. Our state-of-the-art 3D printing techniques enable accelerated product development and shortened turnaround times. At EWOQE, we are committed to providing components that meet your specific requirements with the utmost quality and reliability. We understand the importance of these factors in the industry and are dedicated to meeting your expectations in every aspect. We would be honored to serve as your trusted partner for model making, prototype construction, and 3D printing services.

Request for a quote

BORAN REKLAM LTD.

Turkey

3D Lenticular printing which is used to feel 3D Lenticular Effects such as depth, flip and animation from flat surface without any extra material like glasses. The biggest size of lenticular sheet is 120x240 cm. Lenticular print could be described as a specially prepared image which allows viewing different images at different angles when connected with the lenticular lens. So left and right eyes able to see different particular images at the same time. These different images process in the brain as a whole image. We call this illusion as depth, flip and animation effects. Quote is based on: 1.Quantity 2.Size 3.Designs 4.Packing details Payment Terms :Cache Minimum Order :10 Pieces Lead Time :10 Days Packaging: Wooden Box

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

3D PROTOTIPAI

Lithuania

Multi Jet Printing (MJP). MJP works almost like an ink jet printer. The parts have excellent resolution and the materials have a variety or properties. This technology is primarily used for smaller parts that can be accurate and not very difficult to finish. MJP technology is used to build parts, patterns and molds with fine feature detail to address a wide range of applications. This method is perfect for creating durable, high-definition functional prototypes, rapid tooling such as injection molds, casting patterns and end-use parts. Parts made with MJP technology are beautifully precise, with sharp edges and true-to-cad fidelity. Ultimate adventure of this 3D printing technology - possibility to print assemblies. MJP method is widely used in transportation, energy, consumer products, recreation and healthcare industries. M3 Black and M3-X are durable plastics that looks and feels like injection molded plastics and allows for more rigorous testing and use. The materials is well suit

Request for a quote

MITCHELL AND SON 3D PRINTING SERVICE

United Kingdom

We Provide a full rage of Business Printing from Prototypes, to Promotional Printing and Sales and installation of office and 3D Printing Equipment Bespoke 3D Printing Service: The Core of what we do is providing a bespoke 3D Printing Service. Why 3D Print? Speed to Market, Cost Saving, reduced Waste, Recycled Plastic .. Did you know the most common 3D Printed Material, PLA is a by product of corn and is Biodegradable? CAD ( Computer aided design): The internet is a wash with 3D Models and CAD models of most things these days, but when a customer has a specific need and requires a bespoke item, we offer a full CAD service with willingness to sign an NDA if required

Request for a quote

MITCHELL AND SON 3D PRINTING SERVICE

United Kingdom

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. Mitchell and Son 3D Printing Service provides a totally bespoke 3D Printing Service for all sectors using a range of materials. Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. . It is defined as the process of joining materials to make objects from 3D model data, usually layer upon layer. Benefits of additive manufacturing (3D Printing Below are four major advantages that additive manufacturing can provide to help companies reduce cost, timing, and risk. ... 4 Major Advantages of Additive Manufacturing Reduced Tooling Costs. ... Quicker Speed to Market. ... Easily Test Complex Component Geometries. ... Better Component Quality.

Request for a quote

3DMITECH LTD

United Kingdom

PLA premium printers adopt jam technology to amplify the quality. It is easy to print and an affordable option for manufacturers. It has excellent strength and temperature resistance properties. [FDM] PLA It has excellent strength and temperature resistance properties. PLA 3D printer is used to achieve a matt finish and grainy texture.

Request for a quote

3DMITECH LTD

United Kingdom

Selective Laser Sintering [SLS] Selective laser sintering (SLS) uses a laser as the power source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. Our Services Upload custom models for functional. high-performing 3D pieces. Take the guesswork out of manufacturing development with 3D printed prototypes for meetings, testings and perfection of final parts. Ready-to-manufacture 3D prints with one step production from raw material to final part. Available Materials for SLS 3D Printing - About Arnite® T AM1210 (P) - Nylon 11 - Nylon 12

Request for a quote

3DMITECH LTD

United Kingdom

Digital Light Processing [DLP] Digital Light Processing (DLP) starts with a vat of liquid photopolymer or resin that is cured by a digital light source as it repeats this process to build parts layer by layer. Our Services Upload custom models for functional. high-performing 3D pieces. Take the guesswork out of manufacturing development with 3D printed prototypes for meetings, testings and perfection of final parts. Ready-to-manufacture 3D prints with one step production from raw material to final part. Available Materials for DLP 3D Printing -Ultracur3D® RG 35

Request for a quoteResults for

3d printing service - Import exportNumber of results

45 ProductsCountries

Company type

Category

- 3D printers (9)

- Printing - supplies (9)

- Prototypes, industrial (9)

- Printing - digital (2)

- 3D scanner (1)

- 3D software (1)

- Active electronic components (1)

- Additives for plastics industry (1)

- Advertising design - graphic artists and designers (1)

- Hosting of online services (1)

- Medical services - specialised (1)

- Plastic products for engineering (1)

- Plastics moulding (1)

- Printers - computer (1)

- Thermoforming, plastics - machinery (1)