- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manual clamping

Results for

Manual clamping - Import export

PARSMEGA MAKINA

Turkey

Valves are generally used to control the product flow under flat-bottom silos with tunnel systems, chain conveyors and conical-bottom silos. It has a wide application area with its galvanized steel structure.

Request for a quote

NORELEM FRANCE

France

The mini clamp is characterised by its small size, positioning accuracy of the clamping arm, and lightweight construction. Mini clamps are fully self-locking. The clamping force is guaranteed even when the pressure is removed through the over dead-centre position of the toggle lever on the clamping arm. The permanent lubrication and special bearing bushings make the mini clamps maintenance-free. They can be operated using dry, oil-free air. The manual closing and locking using the hand lever. Pneumatic opening and closing. Attention: A 5/3-way valve is required, middle position vented. On request: Clamping arm without holes.

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

BORNEMANN GMBH

Germany

Manual marking type holders with hardened type surface, replaceable striking cap, pint stop and clamp screw. This manual marking type holder allows individual labelling, also with company logos. The font size can be designed variably. No fixed norm exists. We make your type holders according to your data.

Request for a quote

IGUS® GMBH

Germany

drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis Move linear torque resistant, completely lubrication-free. The drylin® Q linear construction kit offers the user maximum flexibility in the design Individual housing options such as solid plastic bearings and adjustable complete housings with and without manual clamp are available. Due to the hollow chamber design, the rugged hard-anodised aluminium profile is very light and is suitable for the simultaneous conducting of supply cables. The mounting options are highly variable, among others, using slot nuts; installation size 20 can also combined with all 20/20 aluminium construction profiles. 1. Profile made of hard-anodized aluminum 2. Main body of the carriage made of aluminum 3. Customized clearance adjustment 4. Cover made of solid plastic 5. Gliding elements in high-performance polymer iglidur® J serve as a guide bearing and guarantee optimum running properties drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

FERPLAST SNC

Italy

Dual heat multipurpose. Hand held constant heat sealer. Ideal for sealing clam shells or for tacking. Supplied with a high and low temperature control switch and proportional temperature control system. To spot seal OPS, PSP, PVC, and EPS food container.

Request for a quote

FERPLAST SNC

Italy

The GIGA manual eyelet clamp, thanks to the long steel levers, allows the eyelets used for packaging to be applied with minimum effort. Furthermore, by changing only the punches, it is possible to apply the larger eyelets (like sail for towels and banners from VELA 31 to VELA 80)

Request for a quote

FÖHRENBACH GMBH

Germany

Automatic clamping takes place over disc springs, which are adjustable in the pre-loading and are solved pneumatically to the workpiece change. Manual clamping is made by a knurled knob on the opposite side of the collet. Due to the integration into the existing through-hole of the rotary table, the rotary table with the clamping system remains very compactly. Compact High run-out accuracy Easy to operate Retrofit possible

Request for a quote

NORELEM FRANCE

France

Housing steel. Clamping lever plastic. Threaded spindle grade 12.9. Version Housing nickelplated. Clamping lever, spindle black oxidised. Note Manually operated clamping elements for static clamping tasks. Manual clamping process using the freely adjustable clamping lever. The floating clamp ensure symmetrical application of force onto the rail. Up to 50,000 static clamping cycles (B10d value). In general, a friction connection is created between the clamping element and the the linear guide on the open faces of the profile guide rail so that the ball guide tracks are not damaged. The retaining force is tested on an oil smeared profile guide rail. An adapter plate, dependent on the type of carriage used, is required for height adjustment.

Request for a quote

PRESSTA EISELE GMBH

Germany

Variable notching possibilities for mullion and transom combinations, e.g. curtain walls, winter garden, sky lights and special designs Manual adjustment of the horizontal blade max. 20mm to the front to cut slots Notch variation: rectangle, one sided angular, two sided angular, three sided angular Notch dimensions: 185mm horizontal, and 210mm vertical at (90°) Profile dimensions: height maximum 280mm, width maximum 300mm Manual adjustment of saw blade height, positioning via mechanical digital display; electronic display optional Swivelling range vertical saw blade 30°-90°-30° (back/mid/front) positioning via mechanical digital display Swivelling range of both, horizontal and vertical saw blade, 30°-90°-30°, positioning by mechanical digital display Material fence on the table swivelled left / right 30°-90°-30°, positioning by scale Depth stop adjustable via hand wheel and slide, read out by mechanical digital display, manual clamping Semi-automatic precise and safe notching...

Request for a quote

FRANKE GMBH

Germany

Cassette with star grip - standard Cassette with star grip or clamping lever for locking at any position on the guide track. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. Please consult us for further information. Cassette with clamp lever Cassettes with clamping levers allow the cassettes to be locked in any position along the guideway. The clamping acts without force on the guide system. It is used for manually movable devices, clamping and holding stops, delivery of tools and processing parts. We would be happy to advise you on application and design.

Request for a quote

NORELEM FRANCE

France

The toggle clamp adjusts automatically to the height of the workpiece. Infinitely adjustable clamping height within 35 mm with approximately constant clamping force without manual adjustment of thrust screw position. The clamping force can be adjusted up to 2.500 N according to requirements using a set screw under the lever in the hinge. The hole pattern in the baseplate is suitable for millimetres and inches.

Request for a quote

NORELEM FRANCE

France

The pneumatic hold-down clamp is suitable for clamping workpieces from above. This clamp is operated with standard pressure compressed air. The large swivel angle of the clamping arm makes it easy to insert and remove the workpieces without any obstructions, guaranteeing optimum accessibility to the workpiece. The block design of the housing offers universal fastening possibilities, which means that the clamp can be optimally adapted to the workpiece being clamped. Self-aligning pads with a smooth or serrated faces can be fitted in the clamping arm, enabling rough or machined workpieces to be clamped. These pneumatic clamps can be placed in multiple positions on the workpiece and operated in any particular order. They can be controlled manually or automatically. As these clamps are pneumatically actuated, they relieve the operator, particularly where frequent clamping processes are carried out.

Request for a quote

FUSED MACHINERY

Belgium

Year: 01/2018! Hours of use: 6,100 h Press force: 170 ton Folding length: 4.080 mm Machine is in very good condition and can be inspected under power in France. Immediately available. Standard equipment closed car chassis RAM Spherical suspension of the piston, with the inclination of the piston Electro-hydraulic drive down Hydraulic unit measuring system along the Y axis hydraulic oil in the machine (grease life) oil cooler everse system 2 axle rear system, X and R axes Calibration finger (2 pcs.) Tool pliers2 TRUMPF hand gripper for top tool Manual clamping of the TRUMPF lower tool Edge system Combined with CNC and self-adjusting crown control Intuitive multi-touch controls, Delem T3500T Teleservice on the Internet Built-in Trumpf technology data Network connection Strength 170T Folding length 4080 mm Distance between uprights 2690mm CNC Delem T3500T Gooseneck 420mm Vertical stroke 200mm working speed 15mm/s Number of backgauge axles 4

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

designed for various tool interfaces, e.g. HSK, SK, collet chuck slot and short taper equipped with manual or automatic clamping system permanent grease lubrication or oil-air lubrication

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quote

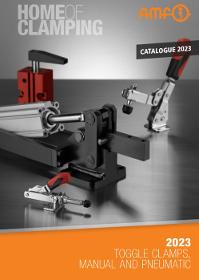

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Toggle clamps from AMF: versatile, strong, durable. Tried-and-tested technology with ever new variants. The benefits of our toggle clamps are highly valued in many fields of application: in the metal industry for drilling, welding, bending, grinding, checking and mounting as well as for the machining of wood and plastic in gluing, drilling, cutting and milling fixtures.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

1999 XYZ PRO 1500 CNC TURRET MILL Control - A.G.E 2 Axis CNC X & Y Variable Speed Head Spindle Taper R8 Spindle speeds to 50 - 4200 RPM Table Size 1066 x 228mm Motor 3hp Coolant Manual, collets, clamps and machine vice Year 1999

Request for a quote

TIRPAR OTOMOTIV MAKINA SAN. VE TIC. LTD. STI.

Turkey

AUTOMATIC SLACK ADJUSTER HALDEX AUTOMATIC SLACK ADJUSTER TM SLACK ADJUSTER MANUAL 3 HOLES SLACK ADJUSTER MANUAL 5 HOLES SLACK SPRING DRUM SPRING BRAKE DRUM BRAKE CHAMBER DISC SPRING BRAKE DISC BRAKE CHAMBER AIR TANK W/CLAMP KIT AIR TANK W/STAND AIR TANK CLAMP KIT

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-4/90 P=30 kW, n=3,000 RPM, M=1,000 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with internal and external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 515 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-2/90 P=15 kW, n=1,500 RPM, M=500 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1.68 : 1 - Manufactured length (up to spindle centre): 750 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-1/90 P=7 kW, n=3,500 RPM, M=150 Nm Construction principle: - Positioning and clamping: manual - SK 40 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 495 mm / 645 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

With its unique ergonomic features and ease of use, the device is ideal for mobile use. The scribe marking system type 317 is available with different handles for flexible adaptation and handling. Being a lightweight of 5.5 kg (without controller, pneumatic and chuck), the unit sets new standards. It offers a large marking area of 120 mm x 25 mm at its small dimensions. Via quick interchangeable, optional fixtures it is possible to adopt to virtually any vehicle geometries. The compact controller provides extensive opportunities for data input via PC, barcode scanner, PLC or the integrated keypad. By this keypad the easy creation and selection of the model-dependent imprinting orders is provided. Options • Vehicle-related fixtures with manual, pneumatic or magnetic clamp functionality

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Quality that inspires It isn’t just the price-performance ratio of MANOK that is impressive. With its incredible holding power, precision and rigidity, MANOK has already surprised many users who never would have imagined that this kind of quality could be found in a manual clamping device. In addition, you can also mount an end-stop to the MANOK in no time at all: Simply fasten the inside end-stop directly onto your machine tool table or mount a front end-stop on the face of the clamping taper. That’s it! Absolute versatile implementation MANOK is not only practical and economical, but it is also extremely versatile. For instance, the integrated actuation lever makes this possible by functioning as an additional force accumulator and acts as an anti-vibration device during milling.

Request for a quoteResults for

Manual clamping - Import exportNumber of results

28 ProductsCategory

- Clamp collars, plastic (5)

- Bearings - ball, needle and roller (1)

- Bearings, ball (1)

- Embossing machine tools (1)

- Food packaging (1)

- Industrial tools (1)

- Joints, pneumatic (1)

- Machine tools, metal machining - parts and accessories (1)

- Oils, cooking - machinery and equipment (1)

- Package sealing machinery (1)

- Planing lathes, automatic (1)

- Tempering, metals - machinery and installations (1)

- Trailers (1)