- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetically coupled centrifugal pumps

Results for

Magnetically coupled centrifugal pumps - Import export

SONDERMANN PUMPEN + FILTER GMBH & CO. KG

Germany

Universal drive control for utmost efficiency MAGSON magnetically coupled centrifugal pumps are extremely efficient by nature. Using the SFU frequency converter for optimum adjustment to changing conditions, this efficiency will increase even more. Thanks to leading-edge control technology, the SFU permanently adjusts the discharge rate to specific requirements. Whenever the rate has to be reduced or the pump has to be operated with changing volume flows, using a frequency converter will save you lots of money. Thus, the power required by a pump running at half speed is only 12% of the original demand. So the system operates with optimum efficiency but saves a lot of energy, especially in part-load operation.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

VILLINA LLC

Russia

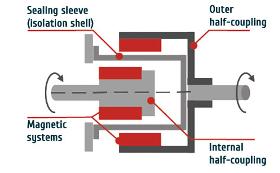

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

SCHMITT-KREISELPUMPEN GMBH & CO. KG

Germany

The MPN Pump Series is particularly suitable for crystallizing media (no air can get inside), toxic or environmentally hazardous media. A small amount of gas in the liquid can also be transferred without disrupting the liquid flow. Materials: PVDF (polyvinylidene fluoride) oder PP (polypropylene) Max. output rate: 400 l/min Max. discharge head: 32 m Motor power: 0.18 - 3.0 kW advantages: »»highest chemical resistance »»robust design - without vulnerable (floating) axles »»low-maintenance through double hydro-dynamic slide bearings with extra big radii »»long-lasting and wear-resistant through axial thrust compensation »»half-open impeller (i.e. solids up to 3 mm of grain size and 10 Vol. % are possible) »»no metal parts are in contact with the medium »»easy to maintain (wear parts can be changed swiftly) »»universally applicable, quiet and compact »»available as explosion proof version for combustible environments

Request for a quote

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Magnetically coupled centrifugal pumps - Import exportNumber of results

6 ProductsCountries

Company type

Category