- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic separation systems

Results for

Magnetic separation systems - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Eclipse’s patented magnetic filtration or magnetic separation systems are the ultimate in filtration technology, providing, quality and environmental benefits. The Filtramag is the ultimate in filtration technology, its’ high intensity magnetic cores make it 1005 effective for use with materials which have lower magnetic permeability such as tungsten carbide and cast iron. With a stainless steel construction it is ideal for use in harsh chemical environments and wash systems. Patented design. Easy installation. Unique dual flow technology™ maximises collection capability. Operates at up to 20 bar. Removes both magnetic and non-magnetic contamination. Minimal pressure drop. In-line connections. Ideal for use in harsh chemical environments. The dual chambered design means that fluid is exposed to the high intensity magnets for the maximum time thus ensuring almost 100% of contamination is removed on first pass through the filter. High intensity magnetic cores ensure particle

Request for a quote

VIRA ISI

Turkey

Magnetic Deaerator and Dirt Separator are used with a single device to dissolve microbubbles, dirt, and air in high performance in heating and cooling installations. Micro smart filter design is the most important element of the system design. Optimum air and microbubble separation and very low flow resistance are available. It also has a high degree of dirt handling. With its magnetic Separator feature, ViraPlus separates the moving metal particles in the installation more effectively and ensures faster cleaning of the installation. It also extends the life of your pump and other connecting equipment by minimizing the damage caused by metal parts to high-efficiency pumps that provide low energy consumption.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and weakly magnetic metals from your product flow. These contaminants can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous metals in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and paramagnetic metals from product flows. These contaminations can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous contamination in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

BLASQEM, LDA.

Portugal

We offer high quality and reliable paint stripping rooms, with different configurations adapted to the requirements of each client. In collaboration with partners with more than 30 years of experience, with engineering and their own manufacturing resources, we study the best technical solutions to meet the expectations of our customers. The blasting rooms supplied by Blasqem can meet different requirements and have different configurations, namely: Shot blasting with several operators Automation of the operation (e.g. robots) Workpiece lifting systems High brightness Double pressure tanks Large capacity depots Different systems and levels of recirculation Magnetic separation ATEX systems No space required We also offer mobile stripping rooms. These solutions can include a complete and compact system for blasting, filtration and recirculation of abrasives.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

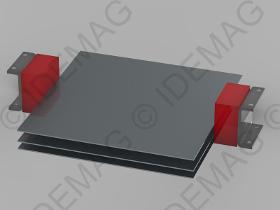

IDEMAG

Spain

The magnetic sheet floaters are designed for separation of magnetic steel sheets, clean , oily or sticky sheets. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. It also operates in automated systems. For a good selection of magnetic floater in the separation of plates, first of all we should know the thickness of the sheets, since it is a critical input to do a good job. One thing to bear in mind is that the magnetic float IDG.FS.RB shall be 90 mm higher than the stack of sheets to be separated. Construction features: * Stainless steel case. * Construction of the magnetic circuit with powerful permanent magnet, which can not be demagnetized. * High resistance welded box. * Threaded holes in the mounting base for a quick assembly * Ceramic or Rare Earths magnets. * Non-standard size. * Sizes and configurations according to customer characteristics. * Available in various magnetic forces.

Request for a quote

ASSFALG GMBH

Germany

The AR series was specifically designed for workpieces that do not have any level contact surfaces. They are only switched on or off with a short compressed air impulse. Workpieces with level, flat, round or irregular surfaces are transported without effort. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. The magnets are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

This magnetic system is specially designed for non-destructive testing of pumped vacuum devices, that required the creation of a uniform magnetic field not only in the center of the operating bore, but in the toroidal region of large size. The system is assembled on the basis of NdFeB permanent magnets.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

AMT&C LLC offers a full range of services in calculations, design and manufacturing of permanent magnet assemblies with required magnetic field configuration. Many years experience in complicated magnetic systems production combined with application of modern most effective magnetic materials permit us to reach high parameters: - to produce, with permanent magnet systems, the magnetic flux density up to 3 Tesla and more; - to reach high homogeneity up to 105; - to create magnetic systems with complicated field pattern; - to produce adjustable magnetic field generators on the basis of permanent magnets. The magnetic field changing rate in such systems can reach 10 Tesla per second.

Request for a quote

TESLA ENGINEERING LTD - MAGNET DIVISION

United Kingdom

Nuclear fusion; the process that powers the Sun, releases energy by means of the fusing of two hydrogen atoms to form one helium atom. Adopting this process on Earth, as part of a next generation power station,1Kg of fusion fuel has the potential to provide the equivalent energy to 10 million Kg of fossil fuel, cleanly and from a potentially limitless fuel. Nuclear fusion reactions require the formation of a plasma of fuel, which can be achieved at temperatures over 100 million degrees. Sustaining this extremely thin and fragile plasma requires a sophisticated magnetic confinement system, which prevents contamination and cooling by the material surfaces. This is where Tesla come in. Tesla is supporting and enabling this international research effort, through the specialist supply of the critical magnetic confinement components for fusion experiments around the World, including: ITER MAST-U Tokamak W7X Stellarator JT-60SA ** Click for more **

Request for a quoteResults for

Magnetic separation systems - Import exportNumber of results

12 ProductsCountries

Company type