- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic machine

Results for

Magnetic machine - Import export

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Cost effective fluid clarification for removing ferrous material. Remove ferrous material, including sludge and chips, from both water soluble and neat oils with high intensity ferrite or rare earth magnets. Typical applications include centerless and heavy stock removal grinding machines, honing, and gear cutting machinery. PRAB’s line of magnetic separators employ high-intensity ferrite or rare earth magnets within a fully energized rotating drum to continuously remove ferrous particles from the flow of liquid. These systems are often used as a pre-filter to limit contaminants reaching subsequent filtration equipment. Magnetic separators are well suited to processes where ferrous and non-ferrous contaminants are mixed with water-based coolants or straight cutting oils. They can also be used to enhance chip processing tasks and help you get the most out of your industrial filtration equipment

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Magnetic chip conveyors transfer wet or dry ferrous scrap without carryover. PRAB’s magnetic chip conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, parts or die scrap without carryover. This scrap conveyor system moves material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates the chain for quiet performance and low maintenance of this scrap handling system.

Request for a quote

STRONG MAGNETS GMBH

Germany

Magnetic separator is one of the most widely used and versatile machines in the industry. It is used to remove iron powder from the reused powder granules. Magnetic separators are widely used in resource recovery, wood industry, mining, kiln industry, chemistry, food and other workshops. The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm. It is also used for iron removal of coal, nonmetallic ore, building materials and other materials. The magnetic system of the magnetic separator is made of high quality ferrite material or rare earth magnets. The average magnetic induction intensity of the barrel surface is 100600 mT.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

LDW is a leading competence centre for DC machines. Our expertise has developed and been proven over many decades. As one of the few globally active manufacturers, we are able to replace machines from other providers with one from LDW – taking into consideration electrical and mechanical specifications and adapting them to customer-specific applications. The machines are individually adapted to the respective application. Our spectrum ranges from small DC machines to very large products. All machines are manufactured individually according to the requirements of our customers. Continuous research and development has in recent years led to great improvements with regard to space utilisation and maintenance requirements of DC machines. In addition, the thermal and magnetic efficiency was increased and materials were optimised. The service life of brushes was significantly extended through this process.

Request for a quote

NORELEM FRANCE

France

Housing brass. Magnetic core NdFeB (neodymium). Smooth design, shielded system. Under no circumstances may Neodym magnets be pressed directly into iron, loss of attractive force due to magnetic short circuits occurs. Diameter “D” ground to an h6 tolerance. These magnets can be shortened by the dimensions “H1” and “H2”. The magnets can be mounted by pressfit, screwingin or gluing.

Request for a quote

FERPLAST SNC

Italy

MG 1020 SEALING MACHINE WITH CLOSING MAGNET Pulse sealers MG 1020 series, with 1020 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. Available models: MG 1020: bench sealing machine with manual closing of the bars MGMI 1020: bench sealing machine with motorized closing of the bars and electric pedal

Request for a quote

FERPLAST SNC

Italy

MG 300 SEALING MACHINE WITH CLOSING MAGNET Impulse sealers MG 300 series, with 300 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. Maximum weldable thickness 0.15 mm (0.30 tot). Available models: MG 300: bench sealing machine with manual closing of the bars MGM 300: bench sealing machine with motorized bar closing and electric pedal

Request for a quote

FERPLAST SNC

Italy

MG 421 SEALING MACHINE WITH CLOSING MAGNET Impulse sealers MG 421 series with 420 mm sealing bar and suitable for sealing polyethylene pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. They can be equipped with special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized closing of the bars. The MG 421 series sealing machines are available with bars with mechanical or motorized closure with a sealing thickness of 3 or 5 mm depending on the model. There are also special models in stainless steel and with 2 parallel welds of 3 mm.

Request for a quote

INGAS LLC

Ukraine

Formula: He General Description: Liquid Helium is a liquid state of aggregation of Helium, a colorless, chemically inert liquid, transparent Gas purity and content of its controlled impurities(vol.%, ppmv) Brand 5.5 99,9995% Areas of use: To ensure the operation of superconducting electromagnets: in medical magnetic resonance diagnostics (MRI) machines, in research facilities such as elementary particle gas pedals and fusion plants; For the basis for ultra-low temperature generation in scientific experiments, Brand 5.5 Helium (He) 99.9995% Neon Ne ⩽1.0 ppmv Nitrogen N2 ⩽1.5 ppmv Oxygen + Argon O₂+Ar ⩽0.5 ppmv Hydrogen H2 ⩽0.2 ppmv Amount of hydrocarbons ΣCₙHₘ ⩽5.0 ppmv Carbon monoxide + Carbon dioxide CO+CO₂ ⩽0.1 ppmv Moisture H2O ⩽5.0 ppmv

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium block magnet, also known as rectangular magnet, square magnet or bar magnet, compared with disc magnet, block magnet is not as commonly used as disc magnet, but their straight line and clean edge offer a pleasing and different visual appearance, what's more, it provides a bigger surface area than disc magnet of same diameter. Block magnet is usually magnetized with north and south pole on opposite square faces, also a multi poles magnetized block is possible with a new magnetizer machine. Block magnet is widely favoured for clamping applications, magnetic sweeper applications, magnetic separators in the food industry, wind turbine generators, flow control systems & water conditioning application and other related industrial applications.

Request for a quote

SOPEM

Belgium

Year - 1986 Window punching and patching machine. Magnetic cylinder for flexible knives. One inside and one outside flexo print units

Request for a quote

DOREY

France

The preparation of tapes before lamination is often an important step in terms productivity. The new GCM works directly from overlays coils thickness from 0.04 to 0.4 mm with or without magnetic tape. Depending on the machine configuration, the hourly rate reaches 1200 format welded, cut to length and stacked. Benefits Fully automatic suction cup brings a destacker hearts in the process, capacity of 1000 sheets 0.7 mm thick. Cleaning sheets before being fed into the machine, each sheet passes PVC or PET in a special cleaning roller. You do not have to worry about the cleanliness of the cards before lamination. High technology, high precision alignment and positioning hearts compared with magnetic tapes. Depending on the heat size, the magnetic strip can be positioned much higher than the overlay on the bottom. In the assembly process, a special ultrasonic welding of two or three layers fixed with accuracy.

Request for a quote

DOREY

France

The preparation of tapes before lamination is often an important step in terms productivity. The new GCM works directly from overlays coils thickness from 0.04 to 0.4 mm with or without magnetic tape. Depending on the machine configuration, the hourly rate reaches 1200 format welded, cut to length and stacked. BENEFITS Fully automatic suction cup brings a destacker hearts in the process, capacity of 1000 sheets 0.7 mm thick. Cleaning sheets before being fed into the machine, each sheet passes PVC or PET in a special cleaning roller. You do not have to worry about the cleanliness of the cards before lamination. High technology, high precision alignment and positioning hearts compared with magnetic tapes. Depending on the heat size, the magnetic strip can be positioned much higher than the overlay on the bottom. In the assembly process, a special ultrasonic welding of two or three layers fixed with accuracy. High efficiency

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Tecnomagnete began its activity in 1974, becoming specialized in permanent-electro magnetic technology applied in the machine tool field. Thanks to original patents, the continous improvement of Quadsystem technology and a winning commercial strategy, Tecnomagnete is the leader for magnetic systems in the industry. Products entail MillTec Grip, for gripping on milling machines, Radial Pole and FlexoMag for gripping on lathes, and the range of MaxX magnetic lifters for lifting ferrous materials.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High collection capacity relative to size No reduction in pressure or flow Easy clean Rapid return on investment Eclipse Magnetic Filtration produce a range of products to filter ferrous materials from your CNC machine's cutting fluids and oils. Magnetic filtration is a positive contribution to companies' environmental policies and ISO 14001 accreditation. Magnetic filtration requires no consumable or disposable products. It extracts 100% of ferrous contamination, drastically reducing the use of disposable filter media. Eclipse Micromag is a compact magnetic filter for standard machine filtration and smaller wash stations. Micromag is compact in size but has massive holding capacity. Units hold 1kg, 2kg, and 4kg of contamination respectively. Micromag is available in a range of sizes to suit a range of applications up to a pressure of 80 bar and a temperature of 140 degrees. Specific Micromag units are selelcted for an application based on required flow rate

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NITTO KOHKI EUROPE GMBH

Germany

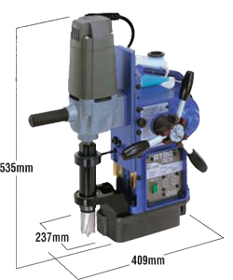

Highly Sensitive Sensor Equipped Side Slip and Inclination detected by a builtin sensor Selfcheck Function The machine checks for faults itself Total Weight Just 7 kg Weight reduced by utilising a moulded plastic Housing Powered by a Battery It makes it possible to drill holes anywhere Magnetic Force Control Function The magnet force is automatically reduced when the drill is not running Soft Start Function The large electric current on startup is prevented by starting the electric drill gently Automatic Drill Stop and Warning Function Unnecessary operations are eliminated

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

CMC TEXPAN oers several solutions for the removal of metal (ferrous and non-ferrous) contaminants, based on dierent principles of operation, hence suitable for various applications. magnetic drum The machine consists of a rotating drum made of stainless steel

Request for a quote

OFFICINE CONTERNO SRL

Italy

Magnetic separators Iron removers are machines used to separate ferrous materials from inert materials in waste processing and recycling plants; these machines are also used in the plastic and wood industries and in mineral crushing facilities for the ceramic and glass industries. Installation on conveyor belts enables optimisation of aggregate recycling processes, thereby reducing costs and increasing profits.

Request for a quote

LM SYSTEMS

Turkey

Magnetic chuck for milling machine and mould clamp for Plastic enjection machine

Request for a quoteResults for

Magnetic machine - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Drilling - machine tools (6)

- Magnets (3)

- Package sealing machinery (3)

- Goods handling systems, continuous (2)

- Cutting - machine tools (1)

- Disks, magnetic (1)

- Electric motors - dC (1)

- Gas mixtures (1)

- Laminating machines and equipment (1)

- Machine tools - metal machining (1)

- Milling - machine tools (1)

- Screen filters (1)

- Wood veneer - machinery and equipment (1)