- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic coupling pumps

Results for

Magnetic coupling pumps - Import export

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Gear pumps with magnetic coupling The magnetic coupling is equal to contact-free drive and seal. Magnetic coupling pumps are used if critical media has to be transported. The seal ensures that the pumps work 100% securely and without leaking. The magnetic coupling is particularly ideal for hazardous substances that should not escape into the enviroment. The coupling is hermetically sealed and can be designed with different sensors for monitoring and in different variations and materials. A magnetic coupling is used in combination with a chemical pump by default.

Request for a quote

SONDERMANN PUMPEN + FILTER GMBH & CO. KG

Germany

Universal drive control for utmost efficiency MAGSON magnetically coupled centrifugal pumps are extremely efficient by nature. Using the SFU frequency converter for optimum adjustment to changing conditions, this efficiency will increase even more. Thanks to leading-edge control technology, the SFU permanently adjusts the discharge rate to specific requirements. Whenever the rate has to be reduced or the pump has to be operated with changing volume flows, using a frequency converter will save you lots of money. Thus, the power required by a pump running at half speed is only 12% of the original demand. So the system operates with optimum efficiency but saves a lot of energy, especially in part-load operation.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Miniature Centrifugal Pumps of the BMK series have been desined for clean watercircuits of up to 160 degree C fluid temperature and up to 7 bar of system pressure. The pumps are equipped with a magnetic coupling. The pumps can be mounted vertically or horizontally. The specific design allows the pumps to operate wear poor. Impellers: peripheral Types of fluid: Industry water Volumetric delivery up to 55 l/min Delivery head up to 58 m Please contact us for delivery quantity

Request for a quote

BÜCHI AG

Switzerland

Mobile gas scrubber (volume scrubbing liquid) : 6, 10, 20, 50, 100 liter Mobile gas scrubber (column diameter): DN 50, 70, 100, 150, 200 Stationary gas scrubber (volume scrubbing liquid) : Customized according to process requirements Stationary gas scrubber (column diameter): DN50 up to DN600 Pressure: -1.0 (FV) to +0.5 bar Temperature exhaust gas: -60 °C to +200 °C Temperature scrubbing liquid: 0 °C to +80 °C Material: Borosilicate glass 3.3, PTFE, ETFE Gas scrubbers are used to neutralize corrosive exhaust gas from reactors. Depending on the scrubbing liquid, they can be used for caustic or acidic vapors. Gas scrubbers are equipped with an ETFE lined, corrosion resistant magnetic coupled pump. The flow rate of the scrubbing liquid can be controlled with the built-in reducing valve. The scrubbing liquid temperature is maintained by a spiral cooler in the liquid circuit.

Request for a quote

VILLINA LLC

Russia

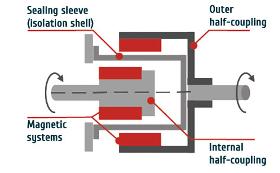

The main parts of magnetic couplings used in GNVC series vertical pumps are the driving (external) and the driven (internal) half couplings, and a sealing sleeve between the half couplings. The exceptional reliability of Villina magnetic couplings is the result of a high-tech design: the enclosed capsular design of the half couplings (enclosed body) secures the magnetic systems from environmental effects; the use of special adhesives allows for fast fixture of domestically produced permanent magnets based on rare-earth elements on the half coupling ferrules; double protection against overheating and demagnetization is implemented using the temperature sensor of the sealing sleeve, which is triggered when the maximum acceptable operating temperature is exceeded by 20 to 50°C, with the use of magnets with Curie point of more than 100°C higher than the maximum acceptable operating fluid temperature; the sealing sleeve made of high-strength Hastelloy alloys

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VILLINA LLC

Russia

Vertical semi-submersible pumps are designed to solve the problem of pumping liquid out of a tank when a part of the pump is within the pumped medium. Pump units are used with the engine speed up to 3,000 rpm. Therefore, the temperature conditions for semi-submersible pumping units are up to 250 degrees. Centrifugal semi-submersible pumps are widely used both in petroleum refining (petroleum and drainage pumps) and the chemical industry, and in the food industry. They are used for transit of various liquids and mixtures including explosive and flammable fluids (oil and gas products, etc.). Semi-submersible pumps are in between surface and submersible units and combine all their advantages, nevertheless, a semi-submersible pump is not designed to carry out specialized tasks for which these two types of units were created. Semi-submersible pumps consist of an electric motor, a working section and immersed sections. The engine is placed on a base plate

Request for a quote

VILLINA LLC

Russia

Modern petrochemical and gas industries typically use horizontal centrifugal canned pump units with magnetic couplings similar to Villina-GNGC type pumps. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. Magnetic coupling pumps combine complete tightness, smooth operation, long service life and high maintainability. A sub-type of horizontal pumping units are high-temperature pumps Temperature of the pumped fluid: -50°C to +420°C; viscosity up to 26 cSt; density 2,000 kg/m3 maximum; mass concentration of solid non-abrasive inclusions up to 0.2%; size 0.2 mm maximum Permanent magnets (SmCo) with an operating temperature of up to 450°C are used for operation in these temperature conditions. The pump, a part of the pumping unit, is a single-stage or multi-stage horizontal centrifugal section-type

Request for a quote

VILLINA LLC

Russia

ADVANTAGES - GNVC-P vertical semi-submersible pumps are developed and manufactured according to individual parameters of the Customer and in compliance with normative documents. - Time of manufacture: 90 days. - Warranty period: 24 months. - Chemical pumps are capable of pumping liquids with viscosity up to 35 cSt, and density up to 2,000 kg/m3. PERFORMANCE SPECIFICATIONS - Purpose: transit of corrosive, toxic, explosive and flammable fluids; - Pump rate ranges: 1 to 55 m3/h; - Head ranges: 5 to 250 m; - Seal type: a magnetic coupling according to API 685 with a sealing sleeve made of Hastelloy alloy (standard version) ensures 100% tightness; - Temperature of the pumped fluid: up to plus 250°С; - Shaft speed: 2,900 rpm; - Structural design: type VS4 according to API 610, vertical type, fixed installation on the container neck on the base plate; - Submergence: 1 to 6 metres, with a length increment of 10 cm for the choice of a specific immersed part length of the pump.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

VILLINA LLC

Russia

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

SCHMITT-KREISELPUMPEN GMBH & CO. KG

Germany

The MPN Pump Series is particularly suitable for crystallizing media (no air can get inside), toxic or environmentally hazardous media. A small amount of gas in the liquid can also be transferred without disrupting the liquid flow. Materials: PVDF (polyvinylidene fluoride) oder PP (polypropylene) Max. output rate: 400 l/min Max. discharge head: 32 m Motor power: 0.18 - 3.0 kW advantages: »»highest chemical resistance »»robust design - without vulnerable (floating) axles »»low-maintenance through double hydro-dynamic slide bearings with extra big radii »»long-lasting and wear-resistant through axial thrust compensation »»half-open impeller (i.e. solids up to 3 mm of grain size and 10 Vol. % are possible) »»no metal parts are in contact with the medium »»easy to maintain (wear parts can be changed swiftly) »»universally applicable, quiet and compact »»available as explosion proof version for combustible environments

Request for a quote

VILLINA LLC

Russia

The magnetic coupling drives for stirring devices are designed to be installed immediately into the tank and provide the necessary stirring of the product. The drive is electrically driven and consists of two half-couplings (driven and driven magnetic half-couplings), bearing assembly and the stirring device itself. Stirring devices (mixers) are of several types: paddle, anchor, propeller, U-type, etc. We develop and supply turn-key solutions for our customers. Magnetic coupling drives for stirring devices are custom-tailored for each specific customer's application in accordance with the sketches provided or according to the parameters specified in the questionnaire form.

Request for a quoteResults for

Magnetic coupling pumps - Import exportNumber of results

13 ProductsCountries

Company type